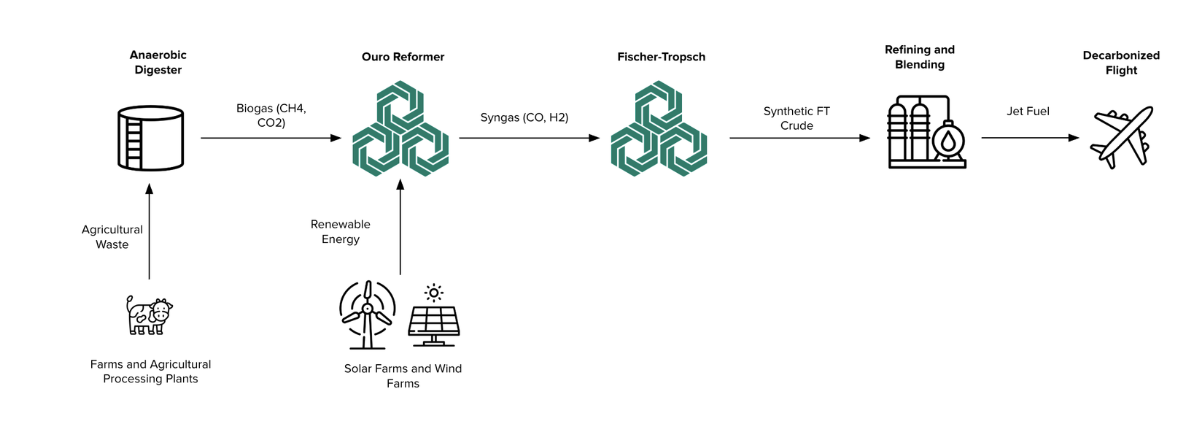

California-based Circularity Fuels has unveiled a breakthrough technology that could dramatically change the future of sustainable aviation fuel (SAF). Using its compact Ouro Reactor, the startup has successfully converted dairy farm biogas into a key ingredient for jet fuel.

On August 19, the company announced a successful trial in California’s Central Valley, where the Ouro Reactor transformed raw biogas from a dairy farm’s manure lagoon into syngas, a vital precursor for jet fuel. Unlike conventional facilities, this electric-powered reactor works without combustion, is small enough to fit on-site, and costs just 1/100th of traditional systems.

“Farmers in the U.S. and around the world are sitting on an untapped goldmine,” said Dr. Stephen Beaton, CEO and Founder of Circularity Fuels. “We’re giving them the ability to turn waste into a profitable product that airlines desperately need.”

The process requires no complex infrastructure. The reactor plugs into a standard electrical outlet and processes raw biogas directly, skipping costly pre-treatment steps. Even contaminants that typically damage reformers are no obstacle for the system, allowing stable operation under farm conditions.

Biogas, mostly methane and carbon dioxide released as manure decomposes has long been an overlooked energy source. While U.S. livestock farms produce nearly a trillion pounds of manure each year, less than 6% of them capture this biogas. By converting it into syngas, and then into jet fuel using the Fischer-Tropsch synthesis, Circularity Fuels believes it can unlock a massive new fuel supply.

“For the first time, farmers will become renewable fuel producers without waiting for pipeline infrastructure that will never come,” Beaton added. The fuel, once produced, can be trucked through existing networks, bypassing the need for specialized pipelines.

The aviation industry faces increasing pressure to adopt cleaner fuels, yet current SAF production meets less than 1% of global demand. Circularity Fuels argues that if its biogas-to-SAF technology were deployed widely across farms, landfills, and wastewater plants, it could produce 42 million gallons per day, enough to supply 70% of U.S. jet fuel needs.

This innovation not only helps airlines meet sustainability targets but could also provide farmers with a new stream of revenue. By turning waste into fuel, Circularity Fuels hopes to bridge the gap between agriculture and aviation, creating what Beaton describes as a “profitable, circular solution.”

The company will showcase the Ouro Reactor at the SAF Global Summit in London next month and plans a full-scale farm demonstration in California later this year.

If successful, this technology could mark the start of decentralized fuel production, reshaping how the aviation industry sources its energy.