An inventive lithium-sulfur (Li-S) battery prototype that can function even when folded or sliced in half has been created by researchers at the University of Electronic Science and Technology of China. This innovation solves serious safety issues with lithium-ion batteries, which can catch fire easily and are prone to damage. Although commonly utilized in gadgets ranging from electric cars to cellphones, lithium-ion batteries have a short lifespan and are susceptible to structural damage. Because Li-S batteries rely on cheap, readily available raw materials and can store more energy, they present a promising alternative.

Li-S batteries do, however, have a number of drawbacks, such as a limited cycling life and safety issues with their lithium metal anodes. A research team headed by Professor Liping Wang has made great progress in improving the stability and longevity of Li-S batteries in response to these constraints. The group suggested enhancing battery stability at high temperatures by employing an electrolyte based on carbonate. Additionally, a layer was inserted between the electrolyte and cathode to stop sulfur from dissolving and lowering the battery’s capacity.

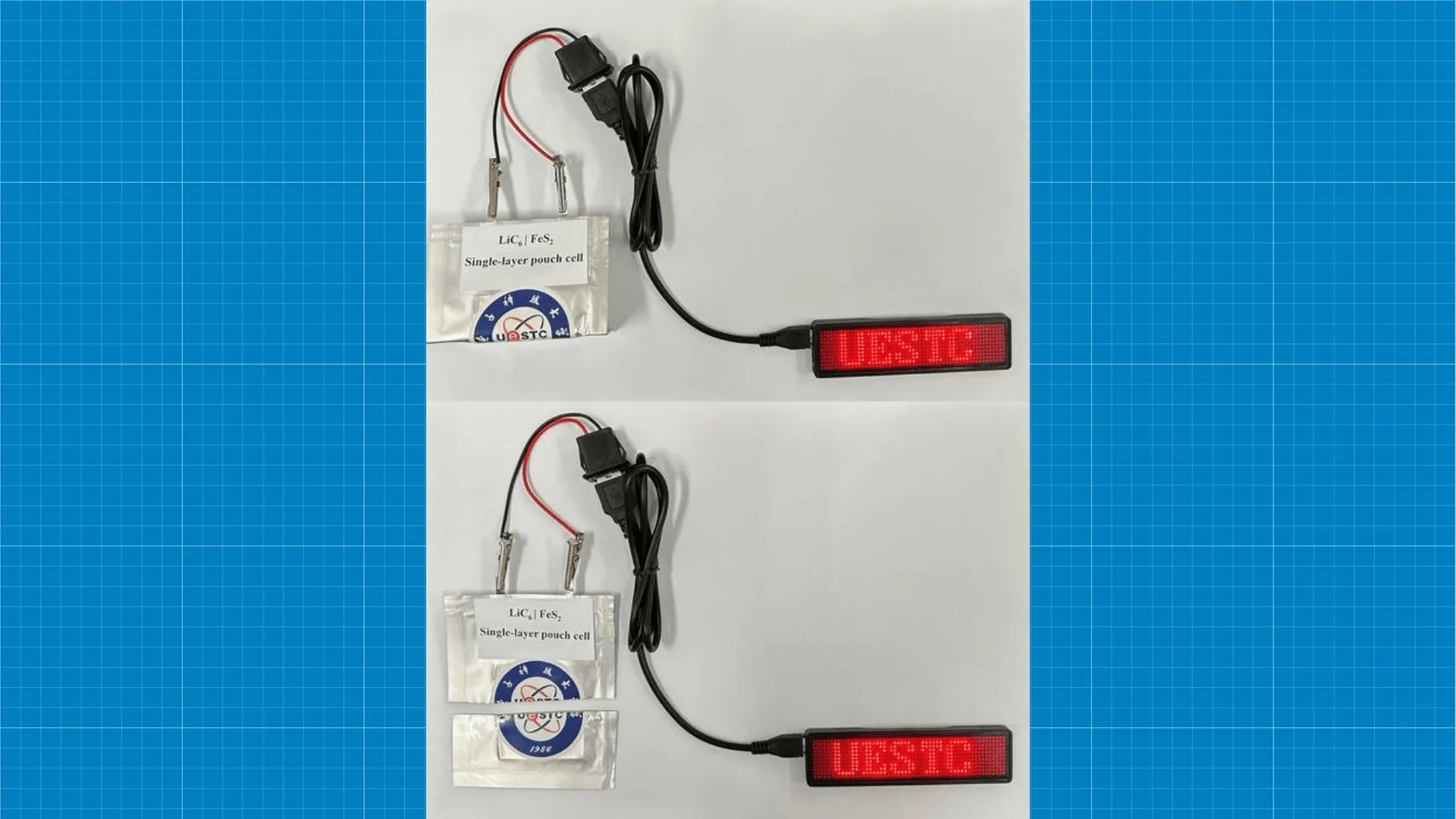

Polyacrylic acid (PAA) was determined to be the ideal material for this extra layer after a great deal of testing. Using an iron sulfide cathode coated with PAA, which remained 72% of its initial capacity even after 300 charge-discharge cycles, the team developed prototypes for pouch and coin cells. The pouch cell’s unique architecture preserved conductive pathways in spite of physical damage, which is astonishing given that it remained functional even after being sliced in half.

This discovery may open the door for the practical application of Li-S batteries, as well as lithium-molybdenum and lithium-vanadium batteries, where long-term stability and high energy density are essential. If these batteries are successful, energy storage options for a variety of industries could be revolutionized.