H3X Technologies, a Colorado-based company, was founded by Jason Sylvestre, Eric Maciolek, and Max Liben, three buddies who met years ago during an EV engineering course. And now, the Department of Energy grant brought them together to develop methods to improve electric motors.

To enable sustainable flying, the company typically manufactures the world’s lightest electric aircraft propulsion systems. In addition, it recently claimed to have developed a new electric motor capable of powering huge commercial planes.

Long-distance flying is still to be facilitated due to the energy density of lithium-ion batteries. As a result, H3X turned to the electric motor to increase its power output.

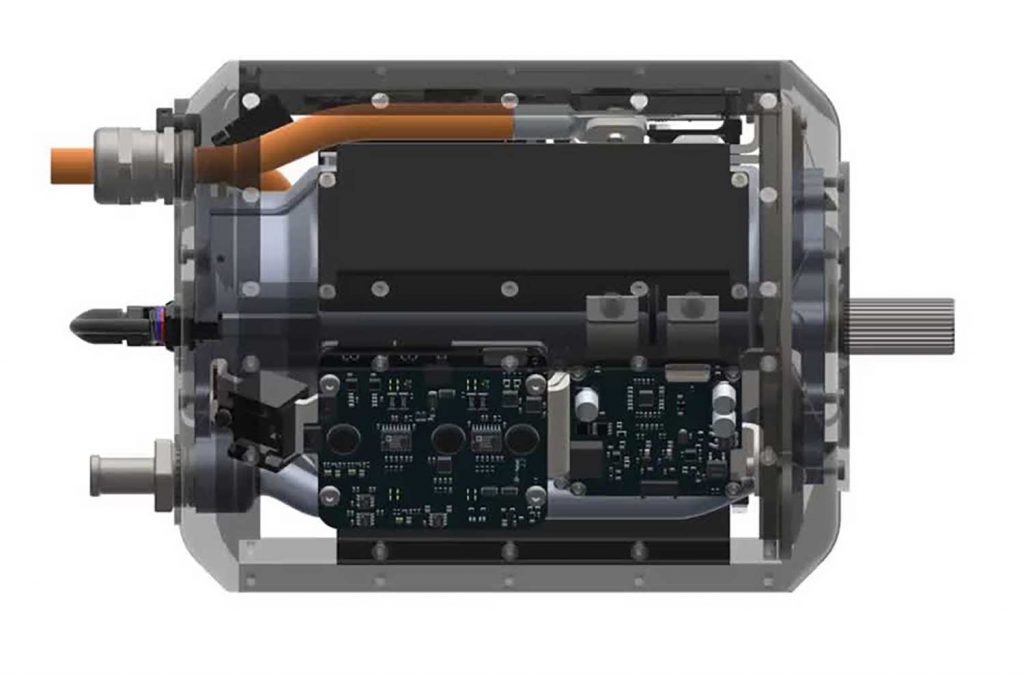

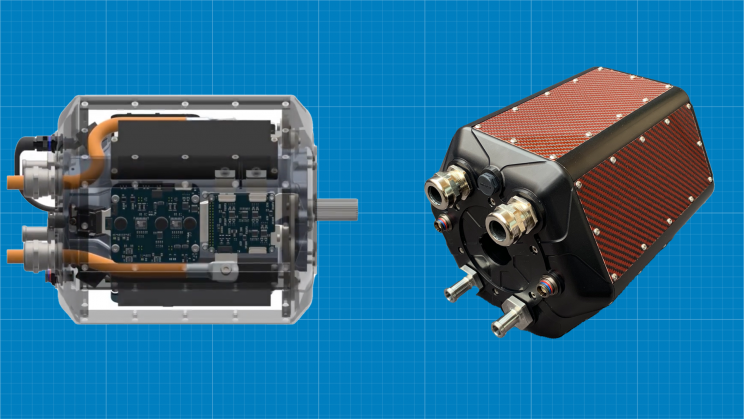

The team started examining the electric motor’s numerous components. For example, a gearbox, a power delivery system, and the primary motor are often separated to provide appropriate cooling space. Failure to do so could result in engine failure.

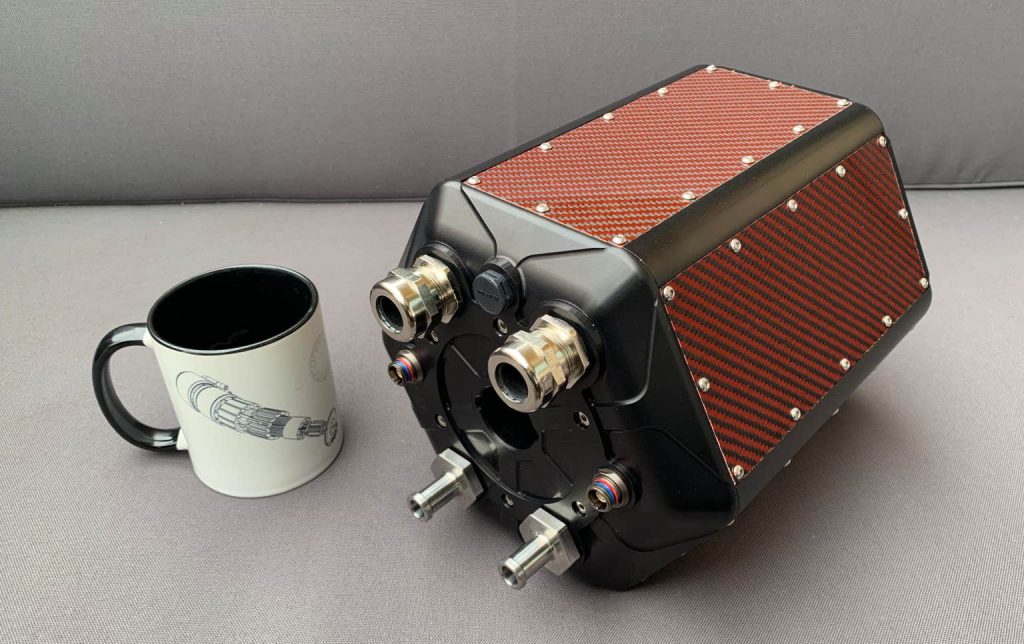

The team could pack all of the components into a system that weighs only 33 pounds (15 kg) without compromising their cooling requirements by including 3D-print materials such as copper. Their motor, called HPDM-250, is notably smaller and lighter.

According to the Advanced Research Projects Agency-Energy (ARPA-E) criteria, a commercial aircraft propulsion system must have a constant power density of 12 kW/kg, according to the Advanced Research Projects Agency-Energy’s (ARPA-E) criteria. On the other hand, conventional electric motors can only produce up to 4kW/kg. The HPDM-250’s power density clocks in at an amazing 13kW/kg owing to its lower weight.

H3X claims its motor can power any mass-sensitive or high-performance application, such as electric boats and urban air mobility. Other long-term aims for the Colorado company include short-haul commercial flights of less than 1000 miles.

Using advanced technologies makes electric motor manufacturing easier and less expensive, Max Liben, Chief Technology Office at H3X, stated. In addition, the staff was conscious of maintenance requirements while assembling the components and has assured that repairing their motors is simple.

These upgraded electric motors are expected to play a part in enabling electric air mobility, even over longer distances, whether powered by electric batteries or hydrogen fuel.