Researchers from the University of Wisconsin-Madison have unveiled a groundbreaking lightweight foam made from vertically aligned carbon nanotubes (VACNT) that outperforms existing materials in absorbing kinetic energy from impacts. This innovative foam, designed for use as a helmet liner, demonstrated nearly 30 times better energy absorption than the liners currently employed in US military helmets. The potential applications extend to mitigating traumatic brain injuries (TBIs), particularly concussions, in both military personnel and athletes.

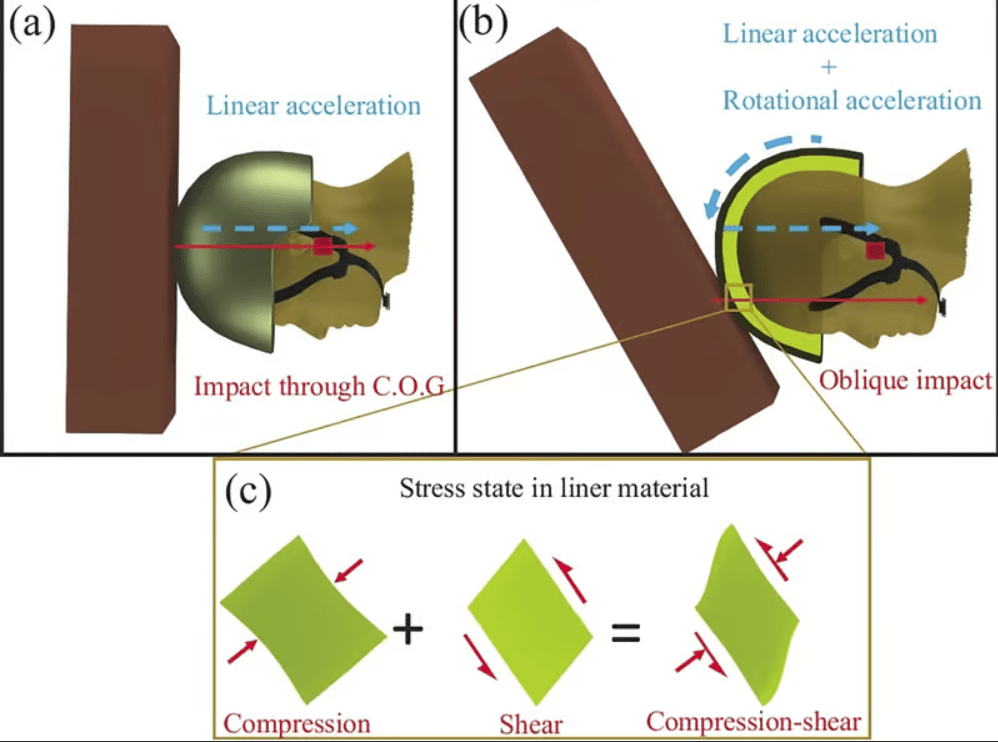

Traumatic brain injury, often resulting from oblique impacts involving a combination of linear and rotational kinetic forces, poses a significant threat to military veterans and sports enthusiasts. The majority of TBIs, including concussions, are associated with these oblique impacts, causing shearing of the brain tissue. To address this, effective helmet liners must limit both linear and rotational motions during impacts.

The researchers, led by Ramathasan Thevamaran, drew on previous work involving VACNT foams—layers of carbon cylinders arranged one atom thick. Unlike traditional helmets that rely on sliding layers to reduce rotational motion, the novel foam developed by the researchers avoids energy dissipation issues associated with sliding layers. The unique deformation mechanism of VACNT foam involves sequential progressive buckling under compression. This allows the foam to absorb large shear strains and return to its initial state once the load is removed.

The study found that at 25% precompression, the VACNT foam exhibited almost 30 times higher energy dissipation in shear compared to polyurethane-based elastomeric foams of similar density, particularly at shear strains up to 50%. This remarkable performance makes VACNT foams ideal as liner materials for advanced helmets aiming to prevent TBIs by managing both linear and rotational kinetic energy during oblique impacts.

In addition to its potential in helmet liners, VACNT foam offers outstanding thermal conductivity and diffusivity. This feature could enable helmets made from the foam to remain cool in hot environments. Beyond protective gear, the researchers suggest broader applications for VACNT foam, such as electronic packaging and systems where it could prevent shocks and contribute to maintaining optimal temperatures for electronics.

In conclusion, the development of VACNT foam represents a significant step toward enhancing helmet technology for improved concussion prevention. The material’s capacity to absorb energy from oblique impacts, along with its thermal properties, opens up possibilities for applications beyond helmets, including in electronics and protective systems.