Researchers at the Swiss Federal Institute of Technology (ETH Zurich) have found the most sustainable solution for the glass fog problem. They have filed a patent application for an ultrathin and 100 percent transparent coating that performs defogging (removing existing fog on a surface) and anti-fogging (preventing the formation of fog on a surface).

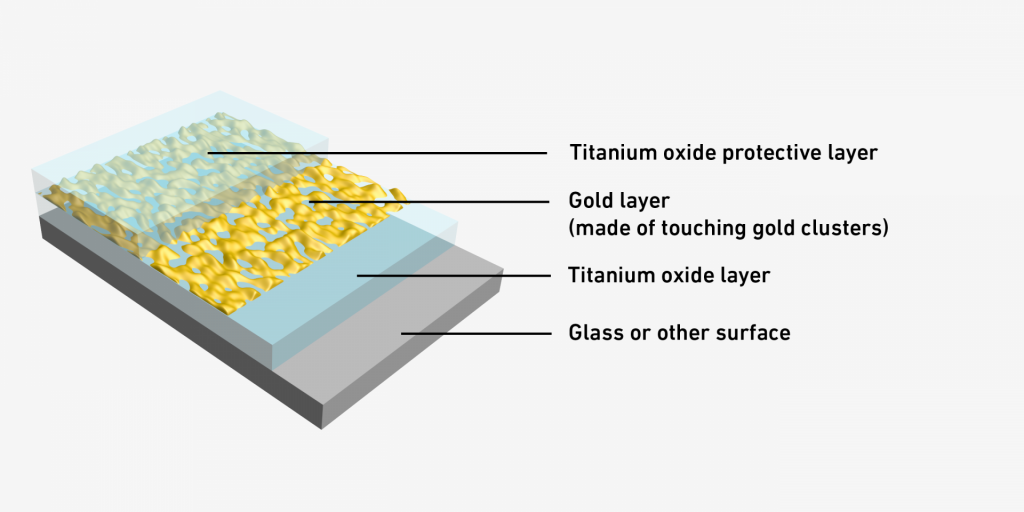

The coating is made up of titanium oxide and gold particles. It selectively absorbs infrared radiations from the sunlight and creates a heating effect that is powerful enough to keep away the fog.

The coating basically employs heat to combat fogging. To heat itself, the coating relies on the most popular and easily available renewable source i.e., sunlight. Interestingly, nearly half of all the energy of sunlight is in the near-infrared spectrum, a wavelength range that we can not see with our human eyes.

The selective absorption of the near-infrared part of the sunlight heats up the surface up to 8°C, preventing the occurrence of fog.

“We achieve this heating effect by fabricating a metal layer (gold) at a very specific thickness (called the percolation threshold), where an optical anomaly occurs. This leads to a strong and broadband absorption of the near-infrared spectrum over just a few nm (10 nm in total),” a Ph.D. student at ETH Zurich and one of the study authors, Iwan Haechler, told IE.

“Our underlying motivation was to show the vast potential of solar energy, and how less sustainable technologies (such as using electricity to prevent fogging) can be circumvented by applying physical concepts and rational engineering. Hence, ideally, our coating contributes to the reduction of electricity consumption for heating,” Haechler told IE.

In normal cars, the hot air from the engine can be used to convectively blow on the windshields and remove fog. Electric engines do not heat up so much, but the gold-based coating might extend the range of electric cars.

Haechler explained, “As the gold layer is only 5 nm thin, it requires only very little gold. The amount of gold per square meter of material would be 100 mg. Assuming that a pair of glasses is about 2×15 cm2, this means that a pair of glasses would use approximately 0.3 mg of gold. This leads to a price of about 0.017 USD for the gold required for a pair of eyewear.”

The limitation of this product is that even though it can work at quite low levels of solar irradiation, it does rely on a certain amount of light. The researchers have already filed a patent, and they are waiting for it to be approved.

The study is published in the journal Nature Nanotechnology.