A team of 25 researchers from Stellantis, CNRS, and Saft in France has completed a four-year research project resulting in a battery prototype. This new battery offers a more efficient and cost-effective energy storage system compared to traditional setups available in the market.

The project, called Intelligent Battery Integrated System (IBIS), marks a significant departure from current electrical energy conversion systems used in most electric vehicles (EVs) worldwide. IBIS combines the functions of the electric charger and inverter directly into the lithium-ion battery modules, eliminating the need for separate electrical conversion modules. This innovation not only saves space in the vehicle but also has the potential to revolutionize the design of electric powertrains.

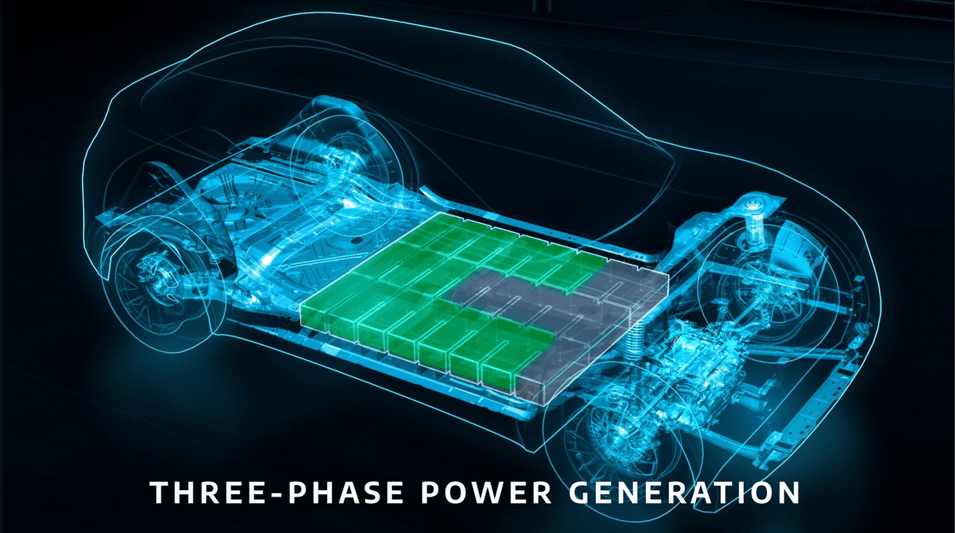

In most EVs today, you find a large battery pack of smaller cells, separate inverters for motor drive, and a charger that converts AC power from the grid into DC for the battery. The inverter then converts DC back into AC for the motors. These three systems are usually located in different parts of the vehicle.

In contrast, IBIS places the electronic conversion boards, handling the power inverter and charger functions, as close as possible to the lithium-ion battery cells. “A sophisticated control system enables alternating current for an electric motor to be produced directly from the battery.”

This approach aims to address various limitations faced by EV customers, such as range, interior space, and affordability, while also improving overall efficiency and reducing the carbon footprint.

“By developing an efficient and cost-competitive technology, the IBIS project offers the opportunity to reduce vehicle weight and the cost of EV powertrain and vehicle manufacturing, while offering a large number of new features.”

Saft’s involvement in the project, as a specialist in advanced technology battery solutions for various industries, enables the team to conduct long-term research programs like IBIS. This includes the availability of turnkey systems, improved battery performance, optimized energy use, and reduced carbon footprint in stationary energy storage and renewable energy integration.

“The intrinsic architecture of the IBIS battery will simplify the maintenance and upgrade of the facility and reduce the site’s carbon footprint.”

The team has been testing IBIS on a demonstration since 2022 and is currently working on a fully functional prototype for road testing. Stellantis plans to make IBIS accessible in their EVs before the end of the decade. If successful, IBIS could mark a significant breakthrough in EV battery technology, leading to more efficient and affordable electric vehicles in the future.