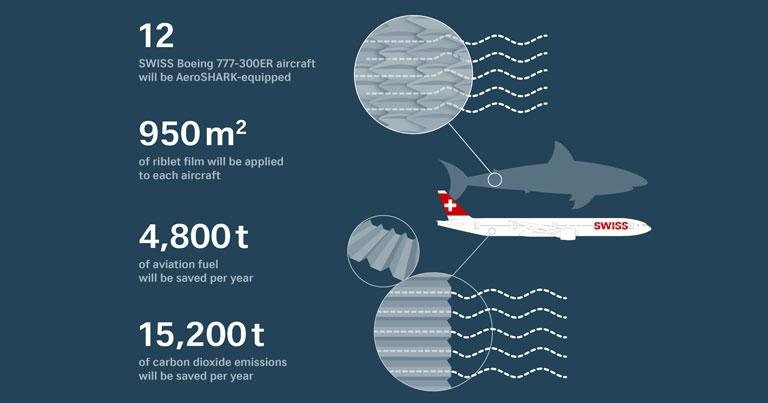

SWISS became the world’s first airline to use the innovative AeroShark technology in its passenger services. The transparent AeroSHARK film, which has been applied to the fuselage and engine nacelles of its aircraft, mimics the hydrodynamic skin of a shark to reduce aerodynamic drag and, as a result, lower inflight fuel consumption and carbon dioxide emissions.

By utilizing sharkskin technology, the global fleet of long-haul aircraft could save nearly five million metric tonnes of kerosene per year. And we’re way past proof of concept! AeroSHARK is a long-lasting bionic film that successfully mimics shark skin and optimizes airflow, allowing for significant fuel savings.

The AeroSHARK film features millions of “riblets”—small protrusions just 50 micrometers high—which replicate the highly hydrodynamic skin of sharks and thus reduce an aircraft’s aerodynamic drag wherever it is applied. The riblet film is easy to apply, even on large commercial aircraft—up to 500 m2 on a Boeing 747-400’s lower fuselage and belly fairing. It is extremely resilient; it withstands large temperature shifts, pressure differentials, and ultraviolet radiation at high altitudes.

AeroSHARK will be installed on Lufthansa Cargo’s entire Boeing 777F freighter fleet beginning in early 2022, making the aircraft more economical and lowering emissions. We estimate a drag reduction of more than 1% in this case. This equates to an annual savings of around 3,700 metric tonnes of kerosene and just under 11,700 metric tonnes of CO2 emissions for the entire fleet of ten aircraft, which is the equivalent of 48 individual freight flights from Frankfurt to Shanghai.

The adoption of the new AeroSHARK technology is a critical step in our larger efforts to reduce carbon dioxide emissions. It also demonstrates our commitment to promoting the use of cutting-edge technologies. We have set ourselves the goal of halving our net CO2 emissions from 2019 levels by 2030 and becoming carbon-neutral in our business and operations by 2050.