The creation of a novel technique that can 3D print artificial heart valves in less than 10 minutes by Harvard University researchers is a significant advancement in the field of 3D printing. This ground-breaking innovation has the potential to transform the manufacturing of heart valves and offer patients who require valve replacements significant advantages.

Damage to or dysfunction of the heart valves can have serious effects on the body, including stroke, arrhythmia, and heart failure. At the moment, making artificial heart valves that are utilized as replacements is expensive and time-consuming. The novel 3D-printed valve the researchers have created could, however, get around these issues.

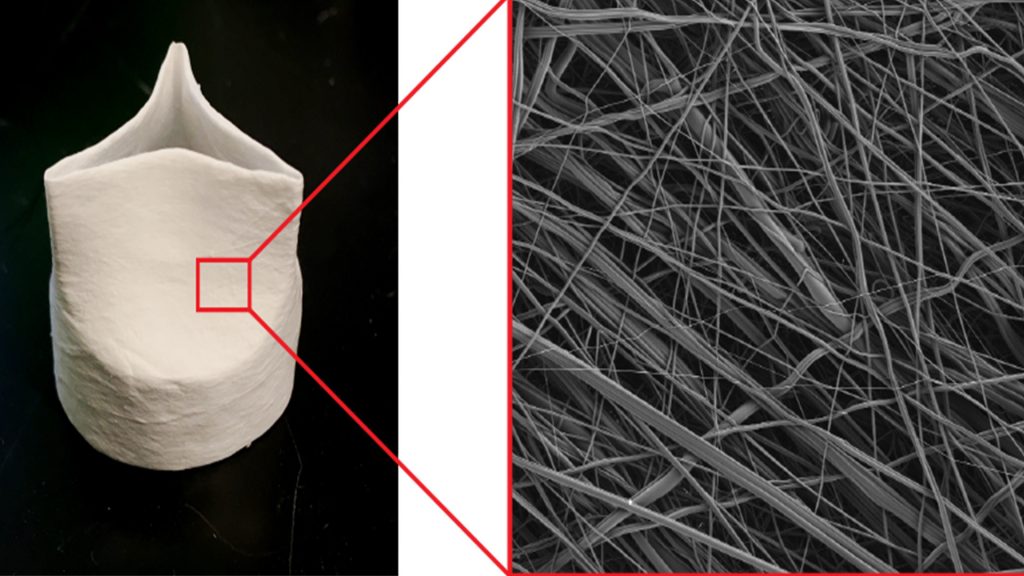

The synthetic valve prototype created by the researchers was successfully tested in sheep, where it effectively regulated blood flow for an hour. The valve is designed to remodel itself and consists of a mesh-like network of nanofibers that mimic the extracellular matrix supporting the growth of natural heart valves.

The fabrication of these nanofibers is achieved using focused rotary jet spinning (FRJS), an additive manufacturing technology that enables the rapid creation of micro or nanofiber scaffolds with adjustable alignments in three dimensions. The researchers created a heart valve-shaped frame and used air jets to push a liquid polymer into the frame, resulting in a flawless nanofiber meshwork. This porous scaffold allows cells to attach and grow, facilitating the development of a native valve that can grow and adapt with the patient over time.

Unlike existing technologies that take weeks or months to produce, the researchers claim that their method can spin a complete synthetic valve in less than 10 minutes. This rapid production process could significantly reduce costs and waiting times for patients requiring heart valve replacements.

The study also highlighted the potential benefits of these synthetic valves for children with pediatric valve disease. The valves manufactured using biodegradable polymer fibers can attach to the patient’s cells and allow for remodeling of the implanted scaffold, enabling the valve to grow and live with the child throughout their life.

The preliminary findings are encouraging, but more research and testing are required before this technology can be applied to people. The long-term effectiveness of the valve implants will be evaluated by the researchers when they carry out more studies on other animal models.

If it works, this novel heart valve creation technique using 3D printing could transform the practice of cardiology and alter how heart valve replacements are performed. It may be able to offer urgently needed patients quicker, more affordable, and tailored treatments, enhancing their quality of life and lowering the risks connected to heart valve problems.