Sound insulators play an important role in life, especially if you’re living next to an airport or a train station. The roar of train engines or jet engines can usually hamper anyone’s day. However, the most important use of sound insulators is in the aircraft themselves. If the jet engines are so loud that they can disturb nearby housing, imagine how it would feel being inside an actual aircraft.

This is where sound insulators come into play, all aircraft are heavily insulated to prevent the sound from the jet and even the noise made by the air whizzing by at high speeds from entering the cabin and rupturing your eardrums. This insulation though comes at a cost and that cost is the overall weight of the plane itself. A conventional sound absorber, like kinetics KUA, has a density of 32 kg/m3. This where this graphene-based aerogel made by the University of Bath comes into play.

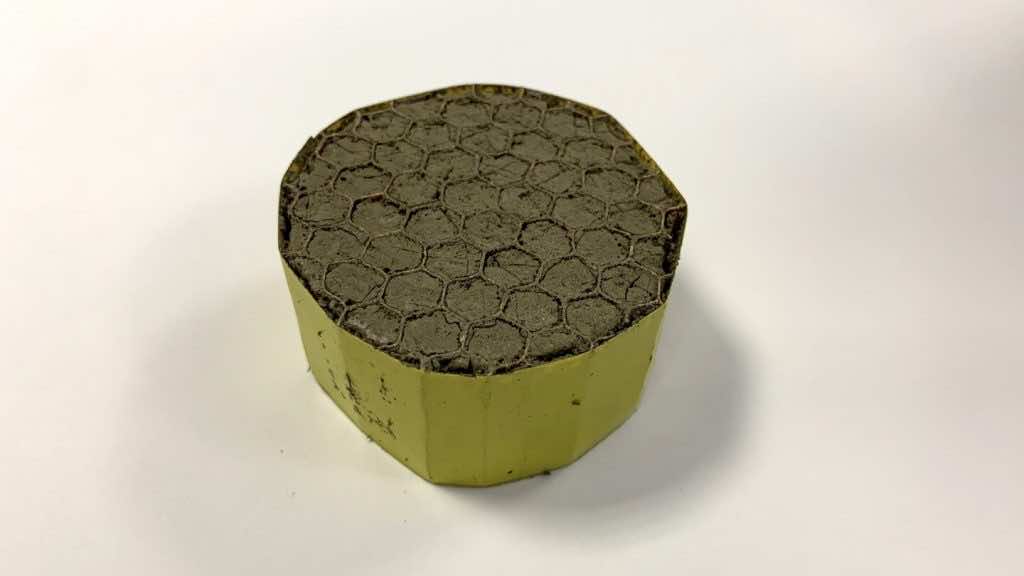

This aerogel might be the lightest sound insulation material ever manufactured. It has the ability to dampen noise by up to 16 decibels despite weighing just 2.1 kg per cubic meter. Compared with regular polyester urethane sound absorbers, this new graphene oxide-polyvinyl alcohol aerogel weighs less than one-fifteenth of an equivalent traditional acoustic foam.

According to Professor Michele Meo, who led the research, “This is clearly a very exciting material that could be applied in a number of ways – initially in aerospace but potentially in many other fields such as automotive and marine transport, as well as in building and construction. “.

They further explained that “We managed to produce such an extremely low density by using a liquid combination of graphene oxide and a polymer, which are formed with whipped air bubbles and freeze-casted. On a very basic level, the technique can be compared with whipping egg whites to create meringues – it’s solid but contains a lot of air, so there is no weight or efficiency penalty to achieve big improvements in comfort and noise”.

According to the study, the aerogel can reduce the current 105-dB engine roar of a jet airliner to something closer to a 95-dB hairdryer. The research was published in the journal Nature Scientific Reports and you can read the original study here. Researchers believe that sound insulation isn’t the only use they can get out of this new material.

They also believe that the aerogel could be useful in other areas like fire resistance, electromagnetic shielding, and they could also develop it further to improve its heat dissipation capabilities. The team said that the aerogel can be commercialized and put into use in just over a year and a half.