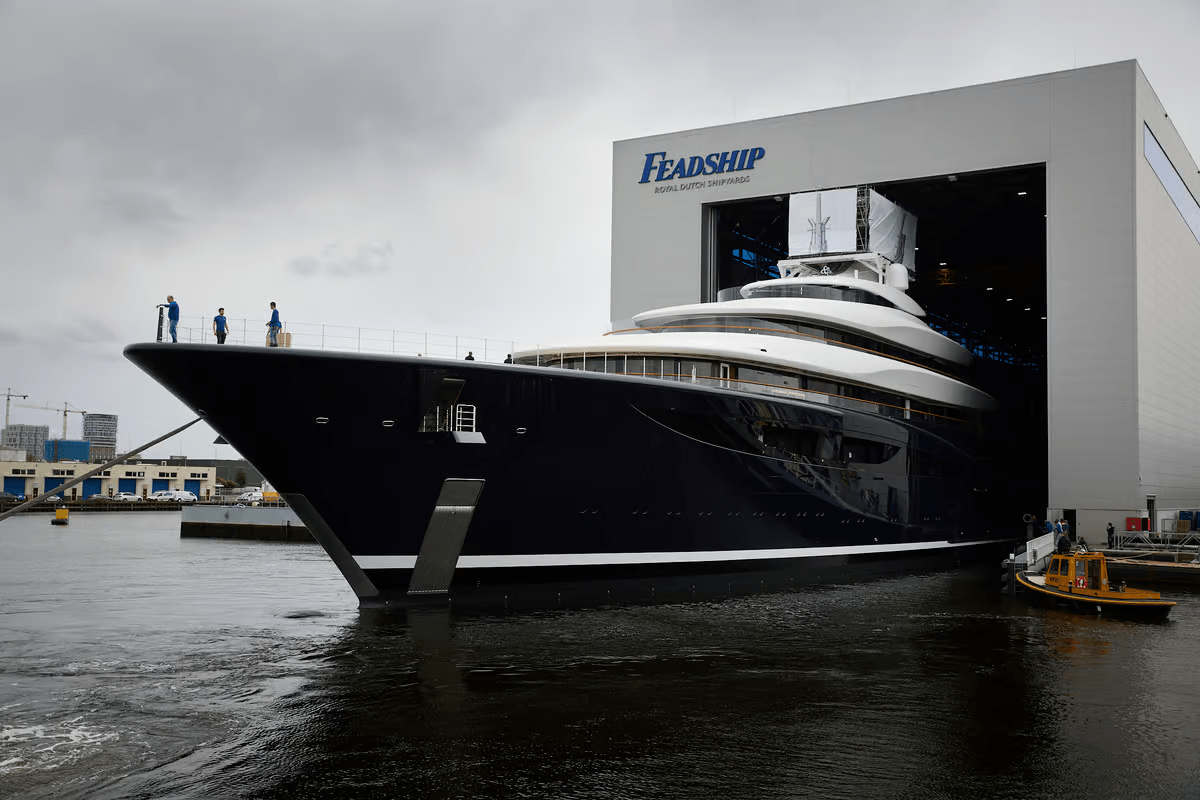

Project 821, a luxurious superyacht, sets the standard for green hydrogen technology as it launches from Feadship’s Amsterdam base.

Although hydrogen is frequently heralded as a major factor in alternative energy, its practical application is crucial to understanding its advantages and disadvantages. Project 821, launched on May 4, 2024, intends to advance hydrogen technology, especially for superyachts. Since there are currently no rules governing the management of fuel cell systems or hydrogen storage at the class, flag-state, or International Maritime Organisation (IMO) levels, this project is essential. As a result, Feadship worked with Lloyd’s Register and superyacht brokers Edmiston to create scaled technology for boats longer than 100 meters (328 ft) as well as possible guidelines and procedures.

There has been little application of hydrogen fuel cells in the maritime industry since they were initially used in the Apollo Moon missions. Project 821 demonstrates several difficulties, especially for such a large ship. Hydrogen is a very efficient energy source, but it needs to be stored under pressure at -253°C (423°F) because it is only 10% as dense as diesel fuel. The ship must carry more than four tonnes of hydrogen for Project 821 to supply 16 fuel cells with DC power via specialized switchboards. The hull had to be extended because this arrangement does not consider problems like hydrogen embrittlement of metals or the unique vent stacks needed to manage water vapor. In addition, if hydrogen is not accessible, the ship must carry methanol to power the fuel cells.

Despite these advancements, hydrogen alone cannot meet all the ship’s power needs. It is only suitable for very short passages under 10 knots (11 mph, 18 km/h), such as entering and leaving the harbor or passing through ecologically sensitive areas. Instead, hydrogen primarily powers the “hotel load,” which includes all non-propulsion power requirements like heating and air conditioning. According to Feadship, hydrogen can cover up to 78% of this load, enabling a week of silent, clean operation while at anchor.

“The aim has been to develop a new, clean technology not just for this project, but for the world,” said Jan-Bart Verkuyl, Feadship Director and CEO of Royal Van Lent Shipyard. “The value of the research, as well as the development of class and flag safety regulations for an entirely new type of energy generation, is an advancement we are proud to have made available to all.”

Source: Feadship