A team of researchers has made a breakthrough by combining the most advanced battery technologies to develop the world’s first anode-free sodium solid-state battery.

The researchers’ approach uses pressure and a stable solid electrolyte to create dense sodium metal. The utilisation of an aluminium current collector guarantees effective, consistent sodium plating and stripping at raised capacities and rates. Given sodium’s abundance and reduced cost, this new battery type promises to be less costly and environmentally hazardous by doing away with the anode and using sodium instead of lithium.

“Although there have been previous sodium, solid-state, and anode-free batteries, no one has been able to combine these three ideas until now successfully,” stated Grayson Deysher, a PhD candidate at UC San Diego and the study’s first author. This breakthrough could create high-capacity, low-cost, quickly-charging batteries for grid storage and electric vehicles (EVs).

Compared to lithium, which only makes up 20 parts per million of the Earth’s crust, sodium is much more abundant, making up 20,000 parts per million. Because of its abundance and the rising expense of lithium-ion batteries due to shortages, sodium is an ideal replacement for these batteries in battery manufacturing.

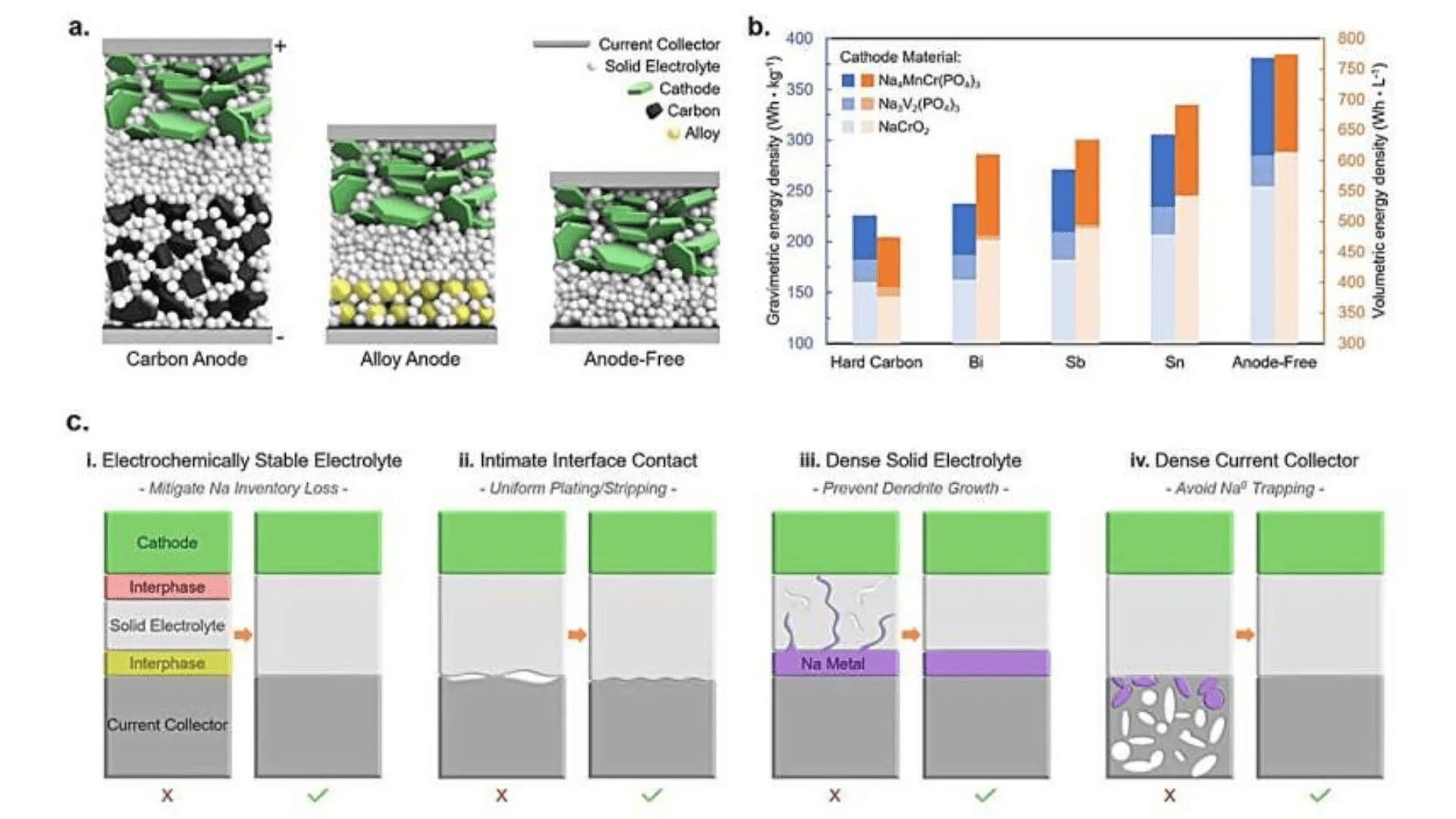

Conventional batteries store ions in the anode while charging and move them to the cathode during operation, which powers devices. On the other hand, anode-free batteries electrochemically store the ions by depositing alkali metal directly onto the current collector. Although complex, this approach has advantages, including higher cell voltage, lower cell cost, and more energy density.

“In any anode-free battery, there needs to be good contact between the electrolyte and the current collector,” Deysher explained. “This is typically very easy when using a liquid electrolyte, as the liquid can flow everywhere and wet every surface. A solid electrolyte cannot do this.”

Liquid electrolytes, though, cause a buildup called solid electrolyte interphase, which gradually reduces the battery’s effectiveness. The team designed a current collector that surrounds the electrolyte to address this. They used aluminium powder, which flows like a liquid, to form the current collector. This powder was then compressed under high pressure during battery assembly, creating a solid current collector while maintaining liquid-like contact with the electrolyte.

Sodium solid-state batteries are usually seen as a far-off-in-the-future technology. Still, we hope that this paper can invigorate more push into the sodium area by demonstrating that it can indeed work well, even better than the lithium version in some cases,” said Deysher.

The findings of this research, conducted by members from the UChicago Pritzker School of Molecular Engineering and the University of California San Diego, were published in Nature Energy.