Engineers at Caltech have developed a material similar to chain mail that can transform from a foldable, fluid-like state into specific solid shapes under pressure.

While explaining the material of the fabric Chiara Daraio, Caltech’s G. Bradford Jones, Professor of Mechanical Engineering and Applied Physics and corresponding author of the study, said that the material has potential applications as a smart fabric for exoskeletons or as an adaptive cast that adjusts its stiffness as an injury heals, or even as a deployable bridge that could be unrolled and stiffened.

“We wanted to make materials that can change stiffness on command,” said Daraio in a statement. “We’d like to create a fabric that goes from soft and foldable to rigid and load-bearing in a controllable way.”

The basic underlying idea is familiar to us.

“Think about coffee in a vacuum-sealed bag,” Daraio added. “When still packed, it is solid, via a process we call ‘jamming.’ But as soon as you open the package, the coffee grounds are no longer jammed against each other, and you can pour them as though they were a fluid.”

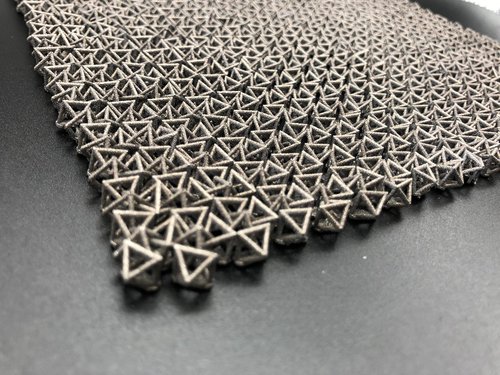

However, the chain consists of complex interlocking shapes, 3D-printed using polymers and metals instead of coffee grounds.

“In this chain mail application, the ability to carry tensile loads at the grain scale is a game-changer,” Caltech mechanical engineering professor Jose Andrade said in the statement. “It’s like having a string that can carry compressive loads.”

The team found that the material can hold up more than 50 times its own weight when in a stiff state during the tests. Currently, researchers are finding ways to switch the material from its rigid to its fluid state and vice versa. For instance, Daraio suggested that cables run through the material like “drawstrings on a hoodie.”

However, it will take some time until the material is ready to help patients recover from an injury; the team plans to miniaturize and optimize the design of structured fabric for practical applications.