3D printing has taken over the world by storm. It has a wide variety of applications and has only been held back because of the size of the 3D printer. However, a team hailing from UC San Diego has created a foam that is capable of expanding up to 40 times its original size.

The study’s abstract reads, ‘In modern manufacturing, it is a widely accepted limitation that the parts patterned by an additive or subtractive manufacturing process (i.e., a lathe, mill, or 3D printer) must be smaller than the machine itself that produced them. Once such parts are manufactured, they can be post-processed, fastened together, welded, or adhesively bonded to form larger structures.’

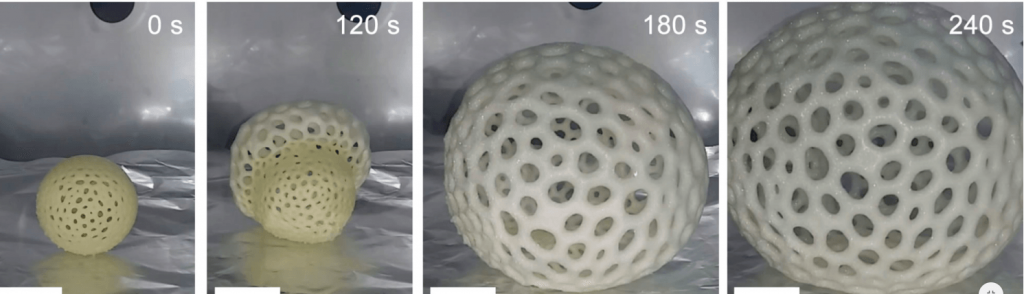

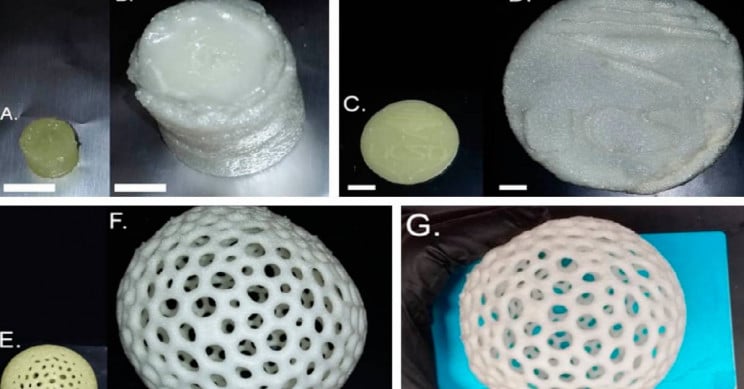

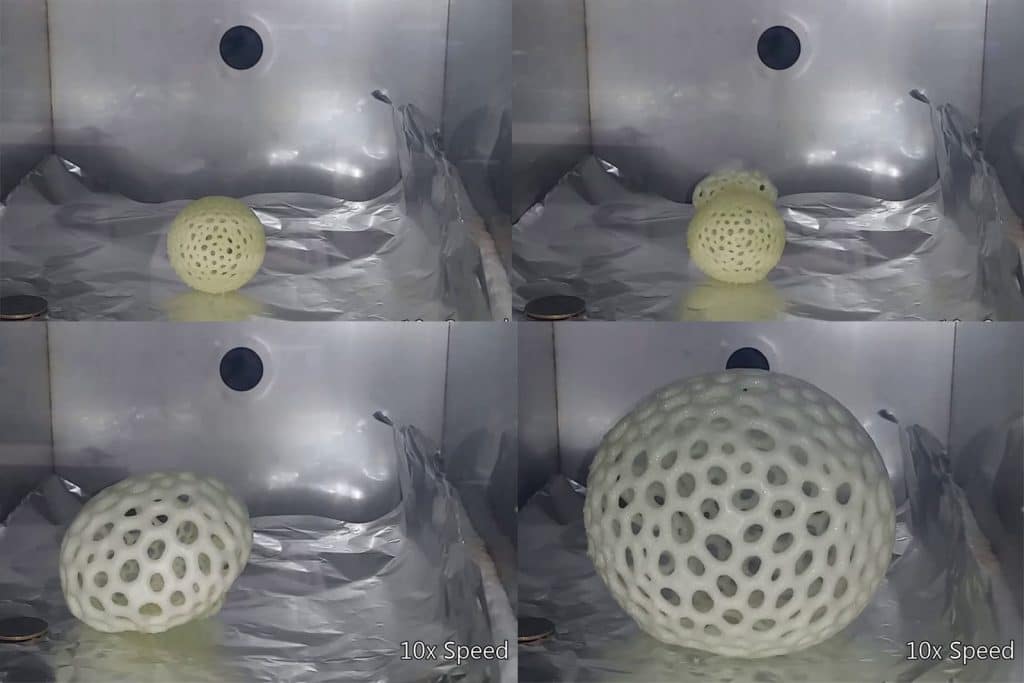

The team said, ‘We have developed a foaming prepolymer resin for lithographic additive manufacturing, which can be expanded after printing to produce parts up to 40× larger than their original volume. This allows for the fabrication of structures significantly larger than the build volume of the 3D printer that produced them.’

The team started work by finalizing a monomer that will act as the building block for the polymer resin. The final chosen one was 2-hydroxyethyl methacrylate. In the next phase, they had to come up with the optimal photoinitiator concentration while also choosing a suitable blowing agent for pairing the 2-hydroxyethyl methacrylate with and following multiple tests; the team was able to agree on a non-conventional blowing agent that is generally utilized in tandem with polystyrene-like polymers.

Once the team from UC San Diego was able to obtain the final photopolymer resin, it tested 3D printing a variety of simplistic CAD designs and heated them at 200°C for up to 10 minutes. The final result showed that the structures had expanded by 4000%.

The researchers are hopeful that this technology can be utilized for lightweight applications including aerospace, energy, biomedicine, and architecture. The study has been published in ACS Applied Materials & Interface.