The electronic devices we use every day have revolutionized the way we live, work, and communicate. However, the production process for these devices often involves hazardous chemicals and toxic gases, which can pose a threat to both human health and the environment.

In an effort to create more environmentally-friendly electronics, researchers at Duke University have developed a new process for fabricating printed electronics using water instead of chemicals.

Duke University’s Aaron Franklin and his team have previously developed fully recyclable printed electronics, and now they have developed a water-based ink that can replace chemicals in the fabrication process.

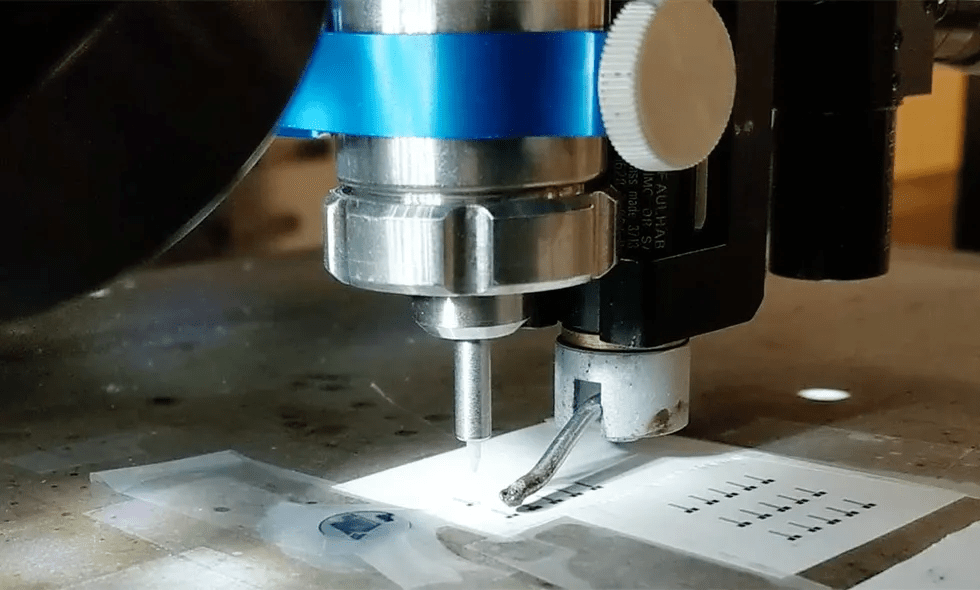

The team used three carbon-based inks to create the recyclable printed electronics – semiconducting carbon nanotubes, conductive graphene, and insulating nanocellulose. To create a water-based ink, they added a surfactant similar to detergent to prevent the carbon nanotubes from clumping together.

However, this resulted in a layer of carbon nanotubes that was not dense enough for a high electron current to pass through. In addition, the surfactant prevented additional layers from adhering to the first.

Traditional processes used high temperatures or harsh chemicals to remove surfactants, which posed human and environmental health risks. Therefore, Franklin’s team developed a cyclical process that involves rinsing the device with water, drying it in low heat, and printing on it again. This process is fully recyclable, uses less water than traditional methods, and is more environmentally friendly.

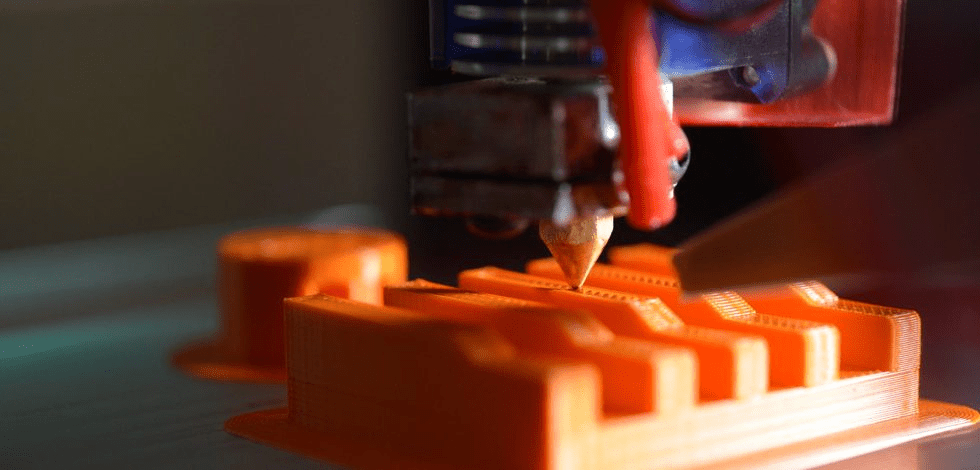

Franklin believes that his approach can be used to manufacture other electronic components like screens and displays. The current fabrication technology relies on hazardous chemicals and toxic gases, which his system could replace.

This environmentally friendly approach may signal to the rest of the field that there is a viable path toward making electronics manufacturing processes much more eco-friendly. With the successful production of water-based transistors using carbon nanotubes, graphene, and nanocellulose, the researchers at Duke University have demonstrated a viable path toward reducing the environmental impact of the electronics industry.