Lawrence Livermore National Laboratory researchers recently reported a net energy gain from nuclear fusion. This breakthrough in fusion energy is a big step toward supplying thousands of homes with carbon-neutral electricity.

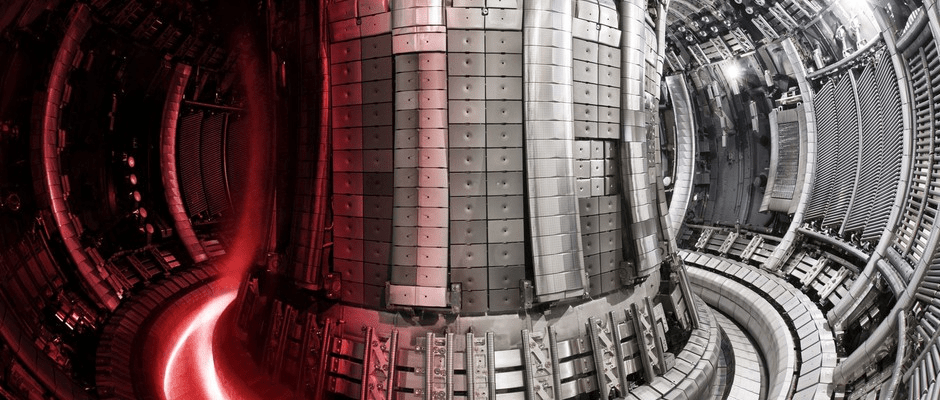

Scientists at Pacific Northwest National Laboratory (PNNL) and Virginia Polytechnic Institute, and State University (Virginia Tech) are helping to achieve this goal by showing how the structure of seashells can be used to improve heavy tungsten alloys for use in high-tech nuclear fusion reactors.

“This is the first study to observe these material interfaces at such small length scales,” said Jacob Haag, the research paper’s first author. “In doing so, we revealed some fundamental mechanisms which govern material toughness and durability.”

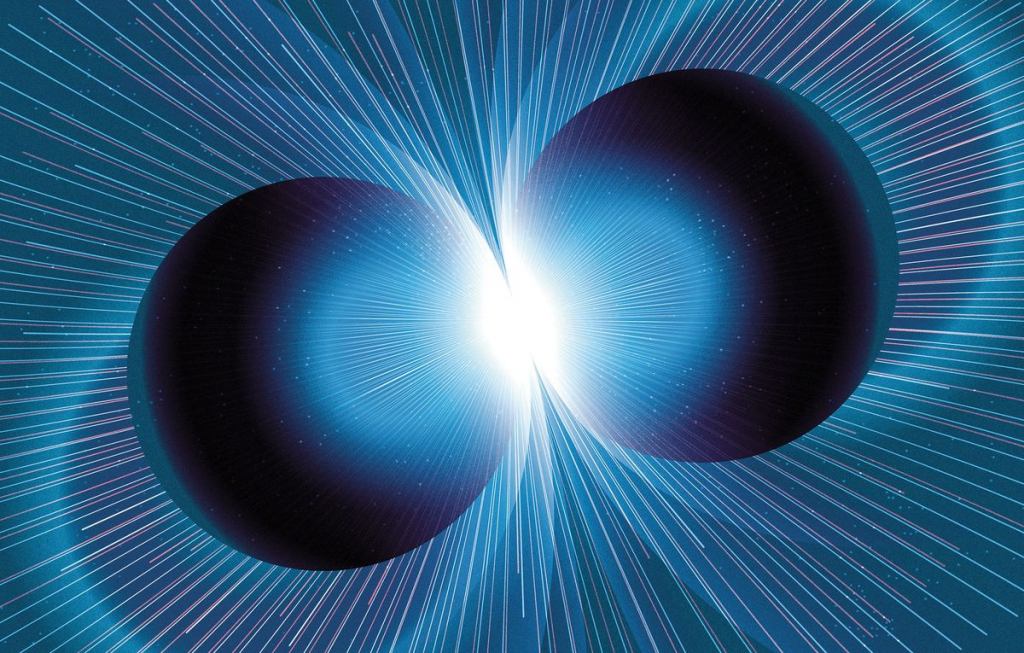

The sun is powered by nuclear fusion. Fusio sioFn processes produce a lot of heat as a result.

But before fusion energy can be used as a power source, researchers must create nuclear fusion reactors that can withstand extreme heat and radiation.

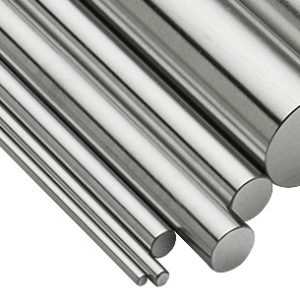

Since it has one of the highest melting points, tungsten is the preferred choice. An alloy that is harder than tungsten alone while keeping its high melting point is created when tungsten is mixed with minute amounts of other metals.

Furthermore, properties like tensile strength and fracture toughness can be altered by the thermomechanical processing of the material. For example, a special hot-rolling method produces tungsten-heavy alloys with microstructures resembling seashells.

“We wanted to understand why these materials exhibit nearly unprecedented mechanical properties in metals and alloys,” said Haag.

Haag and his coworkers employed scanning transmission electron microscopy, energy dispersive X-ray spectroscopy, and atom probe tomography to map the nanoscale composition of the material contact to analyze the microstructure of the alloys.

The nacre-like structure has two distinct phases that make up the tungsten-heavy alloy. The study’s findings reveal that the strong bond between the different phases, including the closely related “hard” and “ductile,” gives tungsten heavy alloys enormous strength.

“While the two distinct phases create a tough composite, they pose significant challenges in preparing high-quality specimens for characterization,” said Wahyu Setyawan, PNNL computational scientist and co-author of the paper.

“Our team members did an excellent job in doing so, which enabled us to reveal the detailed structure of interphase boundaries and the chemistry gradation across these boundaries.”

The findings of the recent study are published in Scientific Reports.