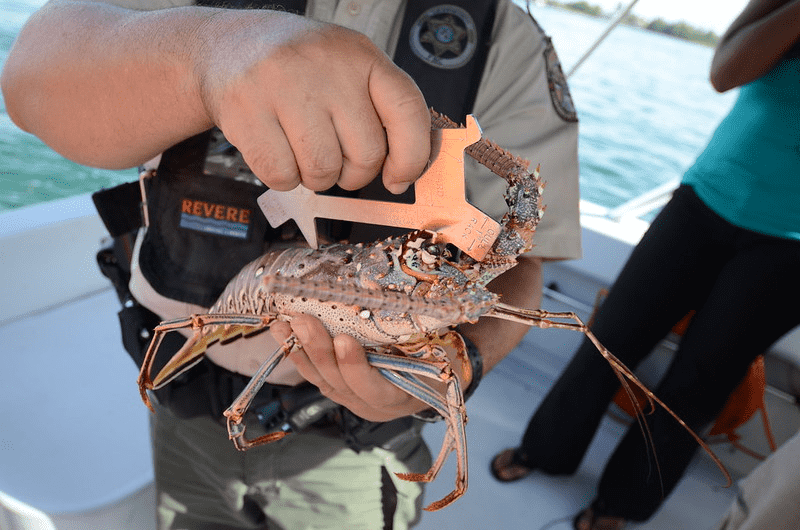

In today’s era, different tech companies are incorporating the principle of sustainability into their newly developed products in order to comply with environmental considerations. Working on the same technique, the researchers at the University of Maryland’s Center for Materials Innovation led by Liangbing Hu have achieved a milestone by manufacturing a battery with recycled materials. The researchers have brought us one step closer to achieving this ambitious goal of fostering a green environment and strengthening sustainability in our ways. For this, they obtained “chitin” from the shells of crustaceans like crabs and lobsters and then combined it with zinc, which further helped in generating electricity.

As we know that electric cars have almost become a trend now and their popularity is continuously gaining momentum. In such circumstances, using those batteries which are not environmentally friendly and that too on a large scale would be an injustice to our environment. For this very reason, researchers have stepped up to develop this state-of-the-art technology. The material “chitin” which has been obtained from the shells of crustaceans has been further processed and transformed into “chitosan”. However, when they processed it again with zinc, an electrolyte was produced that helps in producing electricity within this electrolyte solution. This, in turn, became the process for powering the batteries.

It should be noted that the experiment has only been performed in the laboratory as of now and the results are very encouraging. The findings reveal that even after usage of 400 hours, the electrolyte in the battery still remains effective and capable of delivering more ions that foster electricity generation. Moreover, apart from obtaining chitin from the shells of crustaceans, researchers further revealed that it can also be obtained from materials like squid and the walls of mushrooms as well. According to Graham Newton, who is a Professor of Materials Chemistry at the University of Nottingham, “When you develop new materials for battery technologies, there is usually a significant gap between promising laboratory results and a detectable and scalable technology.”

This shows that the battery is recyclable as well as sustainable and this can further be proven by the fact that after the usage of five months, the substance in the electrolyte can automatically be decomposed. However, the zinc that remains will again be used in the processing of such batteries along with chitin. Graham Newton says that the research has only one significant limitation. He says we see no possibilities about the extraction of chitin on a large scale that may scale up the production of such batteries. So we can say that the research has been confined to the laboratory and cannot be commercialized at the moment due to such constraints.