A new wind-driven propulsion system developed by startup CoFlow Jet aims to revolutionize the cargo shipping industry by significantly reducing fuel costs and emissions. Resembling bridge supports mistakenly installed on a cargo ship, the system employs stationary cylinders with no moving parts to harness wind power, potentially cutting fuel usage by up to 90%.

The shipping industry is facing growing demands to improve fuel efficiency and meet rigorous carbon neutrality goals for 2050, largely because of rising fuel prices. While sails were traditionally utilized for navigation, their impractical nature—requiring sizable crews and relying heavily on wind conditions—led to their replacement by steam and diesel engines.

However, with contemporary concerns about sustainability, there is renewed interest in sail-like technologies. Modern adaptations include kites, composite wind vanes, inflatable sails, and even using the ship’s hull as a sail.

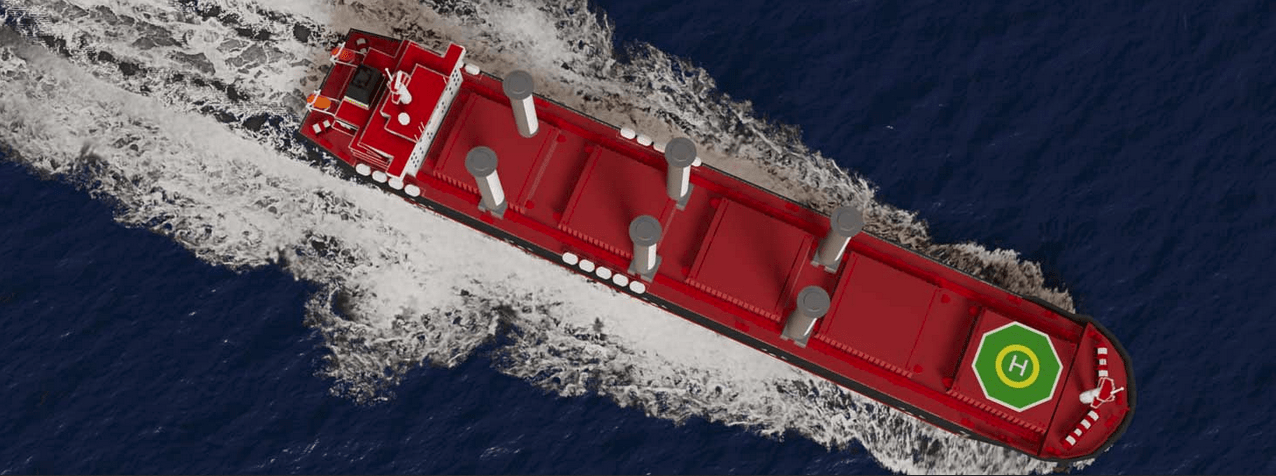

CoFlow Jet’s approach builds on the 1920s Flettner rotors concept but innovates with stationary cylinders. Unlike rotating Flettner rotors, these cylinders intake wind, compress it, and expel it to create thrust without any moving parts. This mechanism provides significant thrust and can reduce fuel consumption by up to 50% for large ships and 90% for smaller ones.

GeCheng Zha, a professor at the University of Miami and the mind behind this system, emphasizes the effectiveness of this wind propulsion method. The CoFlow Jet system’s high lift coefficient and drag reduction enable it to offer a substantial portion of the necessary thrust for vessel movement. Additionally, the system’s retractable cylinders make it adaptable for retrofitting existing ships and maneuvering in harbors.

Zha points out that while traditional sailing ships could achieve complete fuel reduction by relying solely on sails, this new technology provides a reliable and environmentally friendly alternative to diesel engines, crucial for the shipping industry, which contributes approximately 3% of global greenhouse gas emissions.

As pressure mounts for industry-wide change, innovations like CoFlow Jet’s wind-assisted propulsion system could be pivotal in transitioning towards more sustainable maritime operations.

“What’s old is new again,” said Zha. “With the technological advancements of today, wind-assisted propulsion is an efficient alternative to diesel engines. And the major advantage is that it’s environmentally friendly – an effective way to decarbonize the shipping industry that’s responsible for about 3% of global greenhouse gas emissions. The shipping industry has had a tendency to resist change because diesel engines are so powerful but now, with pressure mounting, either willingly or unwillingly, it will have to change.”