One day, a visit to the hospital for a critical bone fracture may not result in bone replacement surgery or medications due to unique material, bone-building micro-robots that may eventually provide a less severe alternative.

Microrobots are essentially microscopic-scale automated devices built to make precise motions in response to certain stimuli—but their small size allows them to move into the body and do jobs that no conventional robot could.

Scientists from Linköping University in Sweden and Okayama University in Japan are working on the technology. The fontanelle tissue, which permits infants’ skulls to be flexible as they travel through the birth canal, prompted the research. Fontanelle tissue progressively transforms into the hard bone after birth. Researchers have now put together materials that mimic this natural process.

“We want to use this for applications where materials need to have different properties at different points in time. Firstly, the material is soft and flexible, and it is then locked into place when it hardens. This material could be used in, for example, complicated bone fractures. It could also be used in microrobots – these soft microrobots could be injected into the body through a thin syringe. Then they would unfold and develop their rigid bones”, says Edwin Jager, associate professor at the Department of Physics, Chemistry, and Biology (IFM) at Linköping University.

The concept was born on a study trip to Japan when Japanese scientists identified a type of biomolecule that may drive bone development in a short amount of time.

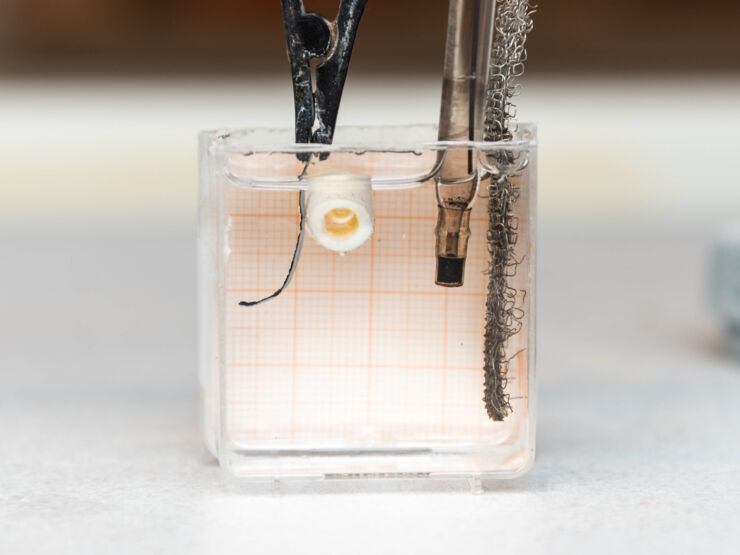

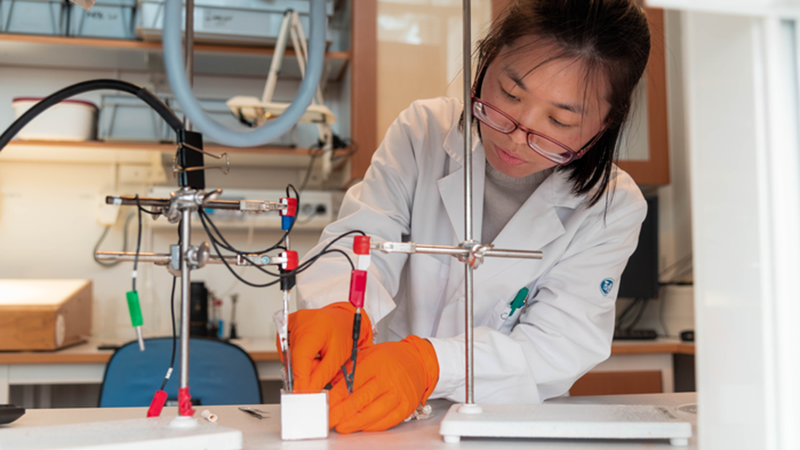

In the study published in Advanced Materials, the researchers built a simplistic “microrobot” that can take multiple forms and vary stiffness. The researchers started with alginate, a type of gel. Next, a polymer substance is generated on one side of the gel. When a low voltage is supplied to this material, it alters its volume, forcing the microrobot to bend in a certain way.

Biomolecules have been attached to the gel’s opposing side, allowing the soft gel material to harden. These biomolecules are isolated from the cell membrane of a bone-forming cell type. The biomolecules cause the gel to mineralize and stiffen like bone when put in a cell culture medium (a medium comparable to the human body that includes calcium and phosphor).

The researchers are particularly interested in bone repair. The soft substance, propelled by the electroactive polymer, could move and fill spaces in bone fractures. When the material has hardened, it may be used to form new bone. The study showed that the material could wrap itself around chicken bones, and the artificial bone that emerges, as a result, grows alongside the chicken bone.

The researchers can control how the basic microrobot bends when electricity is applied by creating patterns in the gel. For example, the robot turns in a semicircle when perfectly straight lines are on the material’s surface, but it bends like a corkscrew when the lines are diagonal.

“By controlling how the material turns, we can make the microrobot move in different ways, and also affect how the material unfurls in broken bones. We can embed these movements into the material’s structure, making complex programs for steering these robots unnecessary”, says Edwin Jager.

Source: Linköping University