Researchers from Sweden’s Chalmers University of Technology have developed the world’s strongest structural battery.

The battery, which is based on cutting-edge structural design, could increase the range of electric vehicles by as much as 70 percent, while also laying the foundation for credit-card-thin mobile phones.

“We have made calculations on electric cars that show that they could drive for up to 70 percent longer than today if they had competitive structural batteries,” said Professor Leif Asp, who led the research team.

While electric vehicles are gaining popularity, major obstacles remain for the transportation industry, particularly when it comes to long-haul ships and airplanes. These vehicles require energy-dense fuels that are light enough to avoid adding excessive weight, but current battery technologies don’t offer a solution. Batteries tend to be much heavier than fossil fuels while delivering far less energy, making electrification challenging for large-scale transportation.

However, structural batteries present a promising alternative. Unlike traditional batteries that act as dead weight, these batteries serve a dual purpose by also performing load-bearing functions within devices. This drastically reduces energy consumption, especially in vehicles, leading to extended range and greater efficiency.

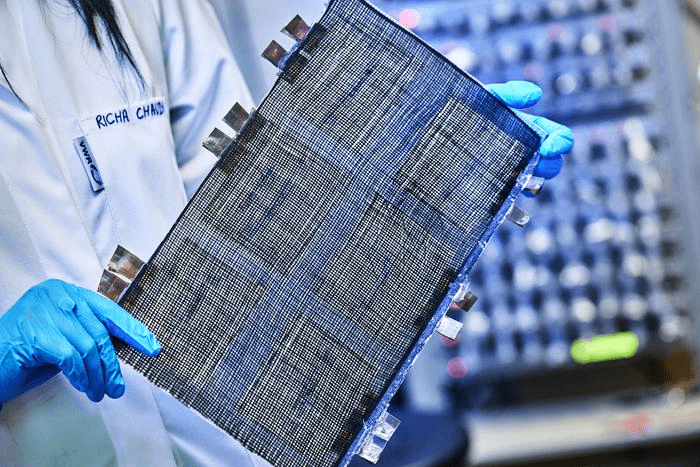

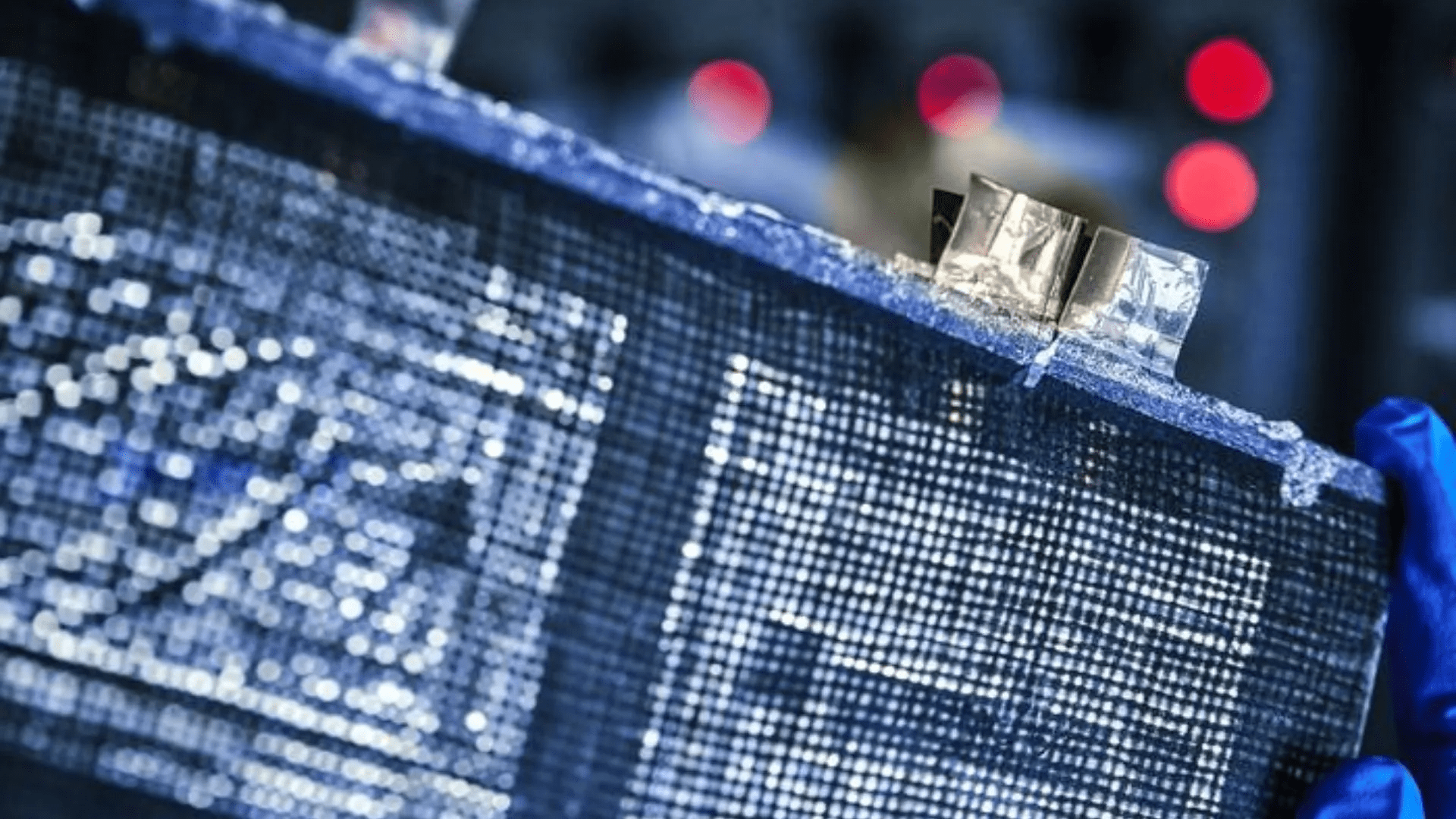

Professor Asp and his team have been exploring the use of carbon fibers in structural batteries since 2018. They discovered that these fibers not only reinforce the structure of the battery but also function as electrodes, making them a powerful component in lithium-ion batteries. In 2021, they increased the energy density of their structural battery to 30 watt-hours per kilogram (Wh/kg), marking a significant improvement from their earlier developments.

Although the energy density of these structural batteries is still lower than conventional lithium-ion battery packs, they don’t need to match that level to be impactful. Asp explained that the benefits of weight reduction and multifunctionality compensate for the difference in energy capacity: “In terms of multifunctional properties, the new battery is twice as good as its predecessor—and the best made in the world.”

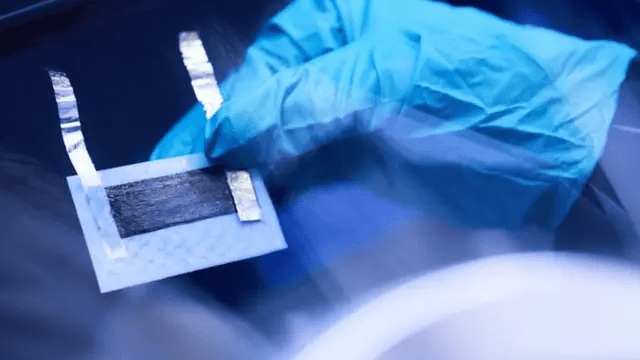

The latest version of the structural battery uses carbon fibers as both positive and negative electrodes, eliminating the need for heavy materials such as copper or aluminum. In previous designs, the positive electrode included aluminum foil, but this has now been replaced by carbon fibers coated with lithium iron phosphate (LFP). This integration of carbon fibers allows the battery to perform multiple roles, reducing overall weight while maintaining high energy efficiency.

The battery also utilizes a semi-solid electrolyte, which not only reduces the risk of fire but also supports safer and more stable energy storage. However, one limitation remains: the battery is not yet capable of delivering high power output. The research team is now focusing on overcoming this hurdle, as they aim to further improve its functionality.

The potential applications of this technology are vast. The increased stiffness of the battery means it can carry loads like aluminum but at a fraction of the weight, making it ideal for use in both portable devices and larger-scale transport systems.

“One can imagine that credit card-thin mobile phones or laptops that weigh half as much as today are the closest in time. It will require large investments to meet the transport industry’s challenging energy needs, but this is also where the technology could make the most difference,” Asp said.