Chinese engineers at the China Railway Construction Heavy Industry Corporation (CRCHI) have used an ancient 2,500-year-old blacksmithing technique to create the world’s largest tunnel-boring machine (TBM).

In 2008, China built its first domestically produced TBM. Over the next decade, the country advanced its technological expertise and emerged as a key player in the global supply of TBM machines.

TBMs are essential to the development of underground infrastructure, enabling engineers to tunnel through various terrains. These machines represent a combination of high-tech innovations, integrating cutting-edge electronics, information technology, and artificial intelligence.

CRCHI engineers revisited the ancient art of blacksmithing, inspired by a 2,500-year-old technique used in crafting the legendary Sword of Goujian. The Sword, forged during the reign of the King of Yue between 496 BC and 465 BC, was known for its intricate and durable design.

In modern TBM design, one major challenge arises from the stress placed on the machine’s bearing, especially given its increased size and the thin surface layer that bears the brunt of the load. As temperatures fluctuate during tunneling, structural weaknesses can develop in the bearings.

To address this, CRCHI engineers adopted a technique similar to how the Sword of Goujian was tempered. Traditionally, blacksmiths used a quenching process, heating the metal and cooling it rapidly in water. However, the sword’s makers applied clay to the surface during the cooling process to ensure a uniform temperature change. By replicating this approach, CRCHI engineers were able to strengthen the TBM’s steel, effectively solving the issue of uneven temperature distribution.

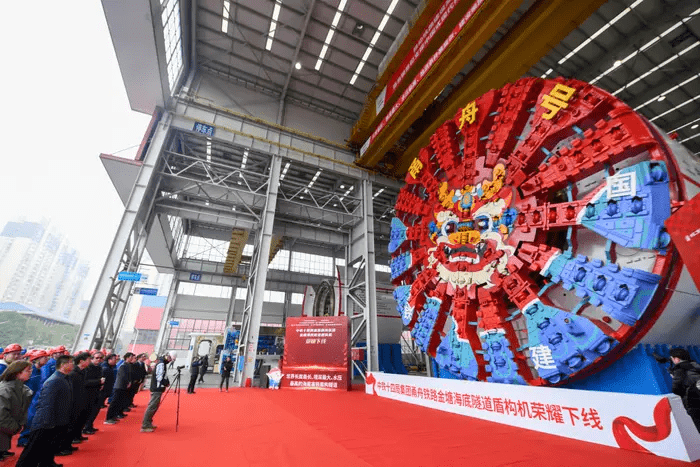

The newly constructed TBM boasts a diameter of 28 feet (8.61 meters) and stands as tall as a three-story building. The machine’s main bearing alone weighs over 10,000 tonnes and contains more than 30,000 individual parts, reflecting the immense complexity of the project.

China’s achievement in producing such a large TBM is the result of years of research, experiments, and collaboration. In 2019, CRCHI established a research institute focused solely on improving bearing designs.

The project also benefited from partnerships with the Chinese Academy of Sciences, allowing the team to experiment with advanced materials and manufacturing processes.

Now, China is not only a leader in TBM production but also in the manufacturing of extra-large-diameter-wide bearings, setting the stage for continued advancements in infrastructure development.