Hysata, an Australian startup, is transforming the hydrogen production industry with its innovative electrolyzer technology. It claims to have the lowest-cost green hydrogen globally. Hysata’s remarkable 95% efficiency rate, which outperforms traditional techniques, has drawn substantial investment to expand manufacturing and develop its unique solution.

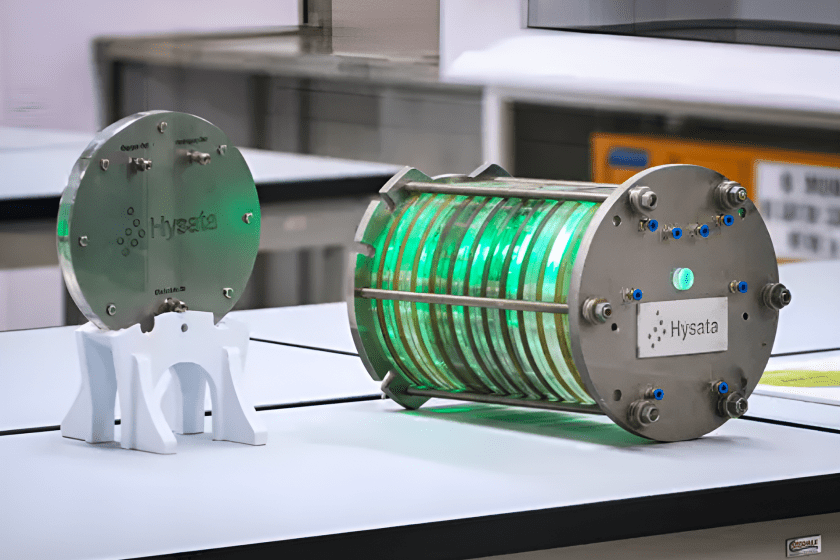

The key to Hysata’s success is its capillary-fed electrolyzer, which was created to overcome the drawbacks of conventional electrolysis techniques. With Hysata’s technique, resistance and energy wastage are greatly reduced as electrode exposure to the electrolyte is maximised, removing hydrogen and oxygen gas bubbles from the electrolyte fluid.

The design of Hysata is a critical innovation; it keeps the electrolyte at the bottom of the device and uses a porous, hydrophilic separator to promote capillary action. This design ensures that each electrode is in direct contact with the electrolyte to minimise energy losses during the electrolysis process.

The exceptional effectiveness of Hysata, confirmed by peer-reviewed research published in Nature Communications, highlights the technology’s practicality. A recent US$111 million Series B investment round focused on increasing production capacity and further refining the technology shows that investors are confident in Hysata’s potential.

Although Hysata’s accomplishments give optimism for decarbonisation initiatives, problems still exist in the more significant electrolyzer business. Due to delays in distributing subsidies, the demand for electrolyzers remains low despite substantial manufacturing capacity, placing a financial burden on manufacturers.

However, Hysata’s economical solution puts it in a favourable position in the face of market uncertainty and presents a strong value proposition for hydrogen manufacturers. Hysata’s technology continues to be a shining example of efficiency in the quest for green hydrogen production as the sector navigates through short-term challenges.

Source: Hysata