Robert Feranec, known for his electronics-focused YouTube channel has released a video that takes soldering to a whole new level, showing us what the process looks like up close!

Under extreme magnified levels, the video allows viewers to see details of different soldering techniques, including Ball Grid Arrays (BGA) and leaded soldering otherwise unseen by the naked eye.

Even if you’ve never used a soldering iron before, the video makes it a fascinating watch. For those familiar with soldering, the footage offers a rare glimpse into what the bonding process looks like at a microscopic level. You can observe how solder behaves when applied properly, as well as what happens when too much or too little solder is used—valuable knowledge for DIY electronics enthusiasts. As Feranec demonstrates, this can help troubleshoot potential issues in your projects before they arise.

“Have you ever seen soldering THIS close?” Feranec asks, and for most of us, the answer is likely no.

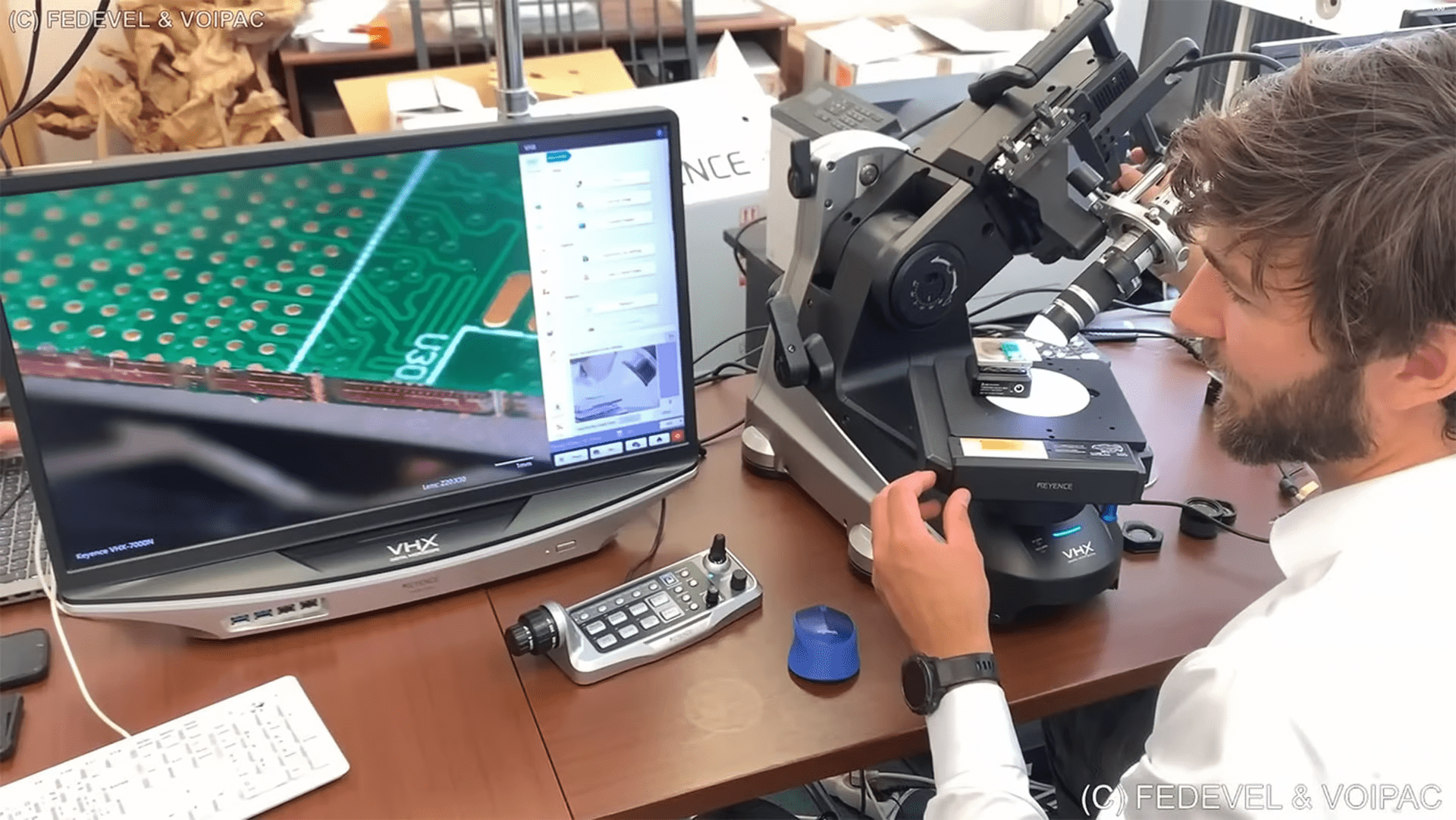

The incredible footage was captured using the Keyence VHX-7000N, a high-end Japanese microscope that launched in 2022. Described as the “world’s first 4K ultra-high accuracy microscope,” it boasts a jaw-dropping 6,000x magnification and the ability to generate 3D views for precise measurements down to micrometers. The device also features HDR support, 20 times greater depth-of-field than traditional microscopes, and an onboard 1TB hard drive for capturing high-resolution images with impeccable clarity.

While the Keyence VHX-7000N is an advanced tool with an equally impressive price tag (upwards of $30,000), its capabilities have allowed Feranec to capture soldering like never before. “That’s a really expensive microscope capable of 6,000x magnification and 4K imagery,” he notes in the video.

For those unfamiliar with the process, soldering involves joining metal components using a filler metal, known as solder. This method is commonly used in electronics, plumbing, and even jewelry-making. The process requires a soldering iron, which heats the solder to its melting point—typically around 360°F (182°C) for lead-based solder—allowing it to form a bond between metals.

Interestingly, soldering dates back to 3000 BC, with evidence of early metalwork discovered in Sumerian swords. In the UK, the word “solder” is pronounced as ‘sole-der’, whereas in North America, it’s pronounced ‘sodder’.

For those looking to get into soldering, you don’t need to break the bank. Basic kits can be found for as little as $12. But if you’re after something more advanced, the Jiizer 01X offers high-tech features like automatic solder feeding and built-in hot air fans for enhanced control.

Starting at $60, this tool aims to simplify soldering by letting you work with one hand, making it a great option for enthusiasts looking for precision and ease of use.

Lastly, if you enjoyed this dive into microscopic soldering, Feranec also recommends checking out a viral video that zooms into the intricate details of an iPhone processor—although, spoiler alert, the video is a fake but still worth watching for its stunning visual effects.