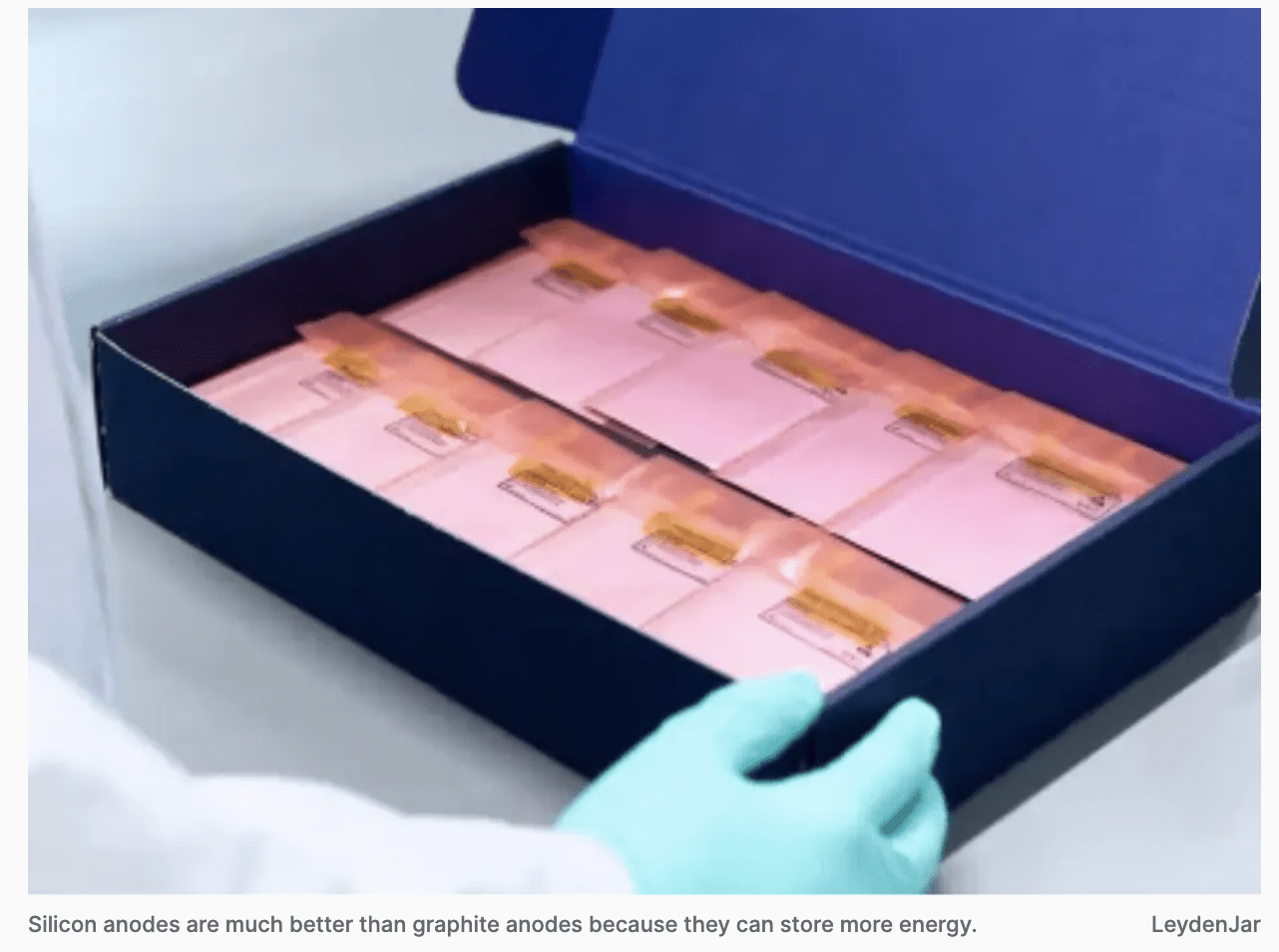

A Netherlands-based company, LeydenJar, has announced a major breakthrough in lithium-ion battery technology. The firm has successfully developed a 100% silicon anode battery that can endure 500 charge-discharge cycles without requiring any external pressure—overcoming a longstanding challenge in battery engineering.

Christian Rood, CEO of LeydenJar, expressed his enthusiasm about the innovation, stating, “We are extremely proud of this breakthrough and the potential it unlocks for the future of energy storage.”

This development could accelerate the adoption of silicon anodes in electric vehicles (EVs) and consumer electronics by addressing a critical durability issue that has hindered their widespread use.

Silicon offers several advantages over traditional graphite anodes, primarily due to its significantly higher energy storage capacity. In fact, silicon can hold up to 10 times more lithium ions than graphite, potentially enabling the creation of lighter, smaller, and more powerful batteries.

For electric vehicles, this means extended driving ranges, making EVs more appealing to consumers. In consumer electronics, it promises longer-lasting battery life in devices like smartphones, laptops, and wearables.

Despite its advantages, silicon anodes have faced a major obstacle—swelling during charge-discharge cycles, which can lead to internal damage and premature battery failure.

“A major challenge has been silicon’s tendency to swell during charge-discharge cycles. This swelling can damage the cell internally, leading to early degradation and failure,” the company explained.

To mitigate this, traditional silicon anode designs relied on heavy clamps applying high external pressure to maintain anode stability. However, this method significantly restricted their practicality, especially for portable and space-sensitive applications.

LeydenJar has successfully tackled this issue by engineering a 100% silicon anode with a unique porous architecture that absorbs the expansion of silicon during battery operation. This eliminates the need for external pressure, ensuring long-term stability.

“With LeydenJar’s new silicon anode technology, the need for external pressure has been entirely eliminated for the first time,” the company stated.

The company’s silicon anodes have surpassed key industry benchmarks, achieving 500 charge cycles before dropping to 80% capacity and 700 cycles before reaching 70% capacity retention—a remarkable feat in battery research.

The elimination of the external pressure requirement opens new doors for silicon anode integration across various industries.

LeydenJar highlighted that “By replacing graphite with ultra-thin 100% silicon anodes, our technology can increase battery energy density by up to 50%.” This directly translates to longer-lasting consumer devices with less frequent charging needs.

The company is actively working with leading battery manufacturers and OEMs to integrate this technology into commercial products. Furthermore, it is exploring applications in electric vehicles, energy storage systems, and next-generation wearables.

LeydenJar’s breakthrough follows recent developments from U.S.-based companies working on similar advancements. Another firm recently revealed plans for fully silicon anode-based batteries, while Amprius Technologies introduced an EV battery featuring a silicon anode that can reach 90% charge in just 15 minutes.