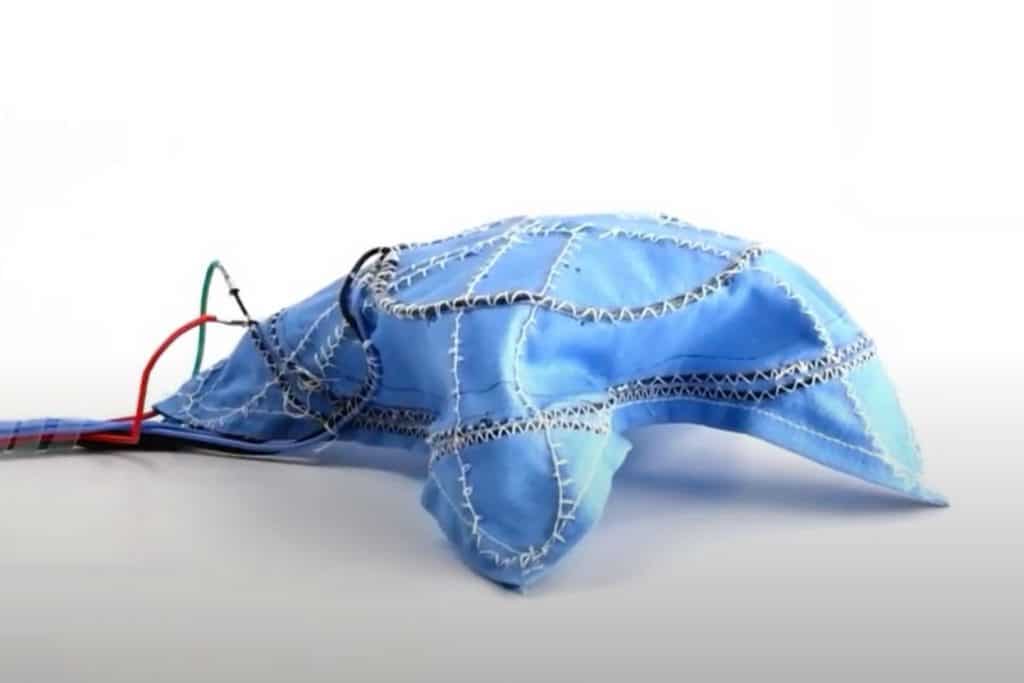

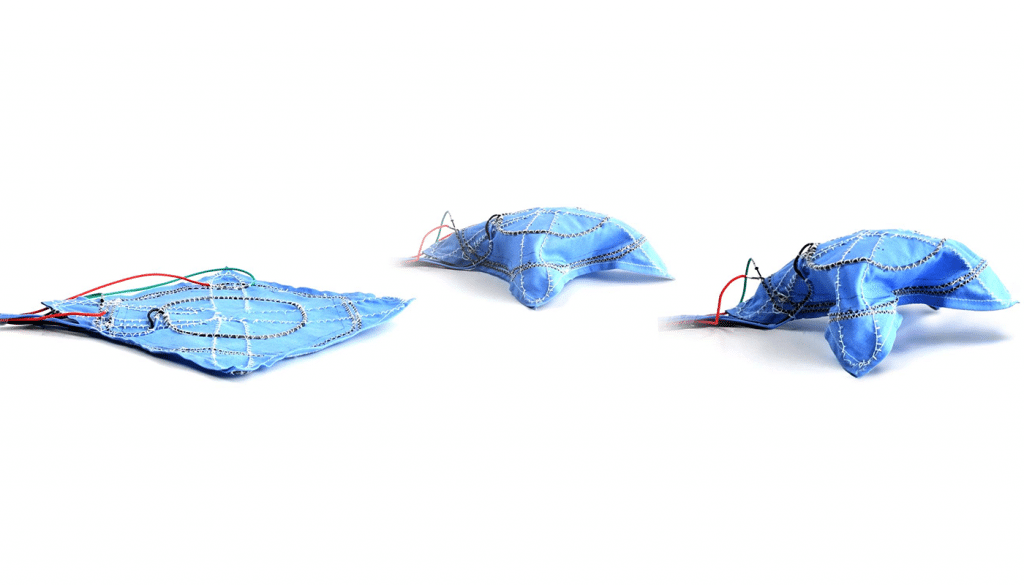

A new robotic fabric has been developed at Yale University by a group of scientists. The unique feature of this fabric is it could change its stiffness and shape as desired. The material automatically adjusts to the optimum level, considering the need for the environment.

Such a fabric material can come in handy in the future uses such as in advanced clothing. This could also be a useful material for tents given its property of changing its surface efficiently. It could also make good material for the robotic parachutes as well.

The team of scientists developed fibers that have multiple abilities and functionalities. Those newly created fibers are then used to form new cloth material by weaving them with different forms of everyday fabric.

Scientists termed the first fiber created with this process as Field’s metal and mostly consists of epoxy particles. This fiber melts at a low temperature of up to 62°C (144 °F). It’s property to change its stiffness and shape upon receiving a little heat makes it a great fabric for different applications.

Once the formation is changed, it is left at room temperature to form a particular desired shape. It could change its shape repeatedly without wearing off.

The lead author of the study said that their Field’s metal-epoxy composite could become as flexible as latex rubber or as stiff as hard acrylic upon the change of temperature. Long fibers of this material can be sewn onto a piece of fabric to give it a supportive skeleton that can be turned off and on.

The process converts the cloth into a smart material that can bear the load and holds weight up to 50-g, flattening most other fabrics. Another cool feature this fabric brings along is that scientists used conductive ink to create sensors that enable the material to detect changes and react favorably.

Rebecca Kramer, another author of the study, said the conductive composite self-coagulates around the individual fibers and did not seemingly change the composition of the fabric. The sensors are visible but don’t modify the texture or breathability of the material, making it comfortable for wearable applications.

The team used a shape memory alloy, which helps the material in changing the shape. Particular shapes can be programmed to the material or a suit made of it. This feature lets the material get back into its original form in case of deformity. The researchers straightened SMA wires into ribbons, allowing them to flatten the shape of the material as desired.

The team showcases the robotic fabric in the video below, and the details on this automated material could be found in the Journal Proceedings of the National Academy of Sciences.