researchers at Tsinghua University have developed a breakthrough 3D printing technique capable of fabricating complex millimeter scale objects in just 0.6 seconds.

The new method, called Digital Incoherent Synthesis of Holographic Light Fields (DISH), represents a major leap forward in additive manufacturing speed and precision. Traditional high resolution 3D printing can take minutes or even hours to produce intricate shapes. DISH compresses that process into a fraction of a second.

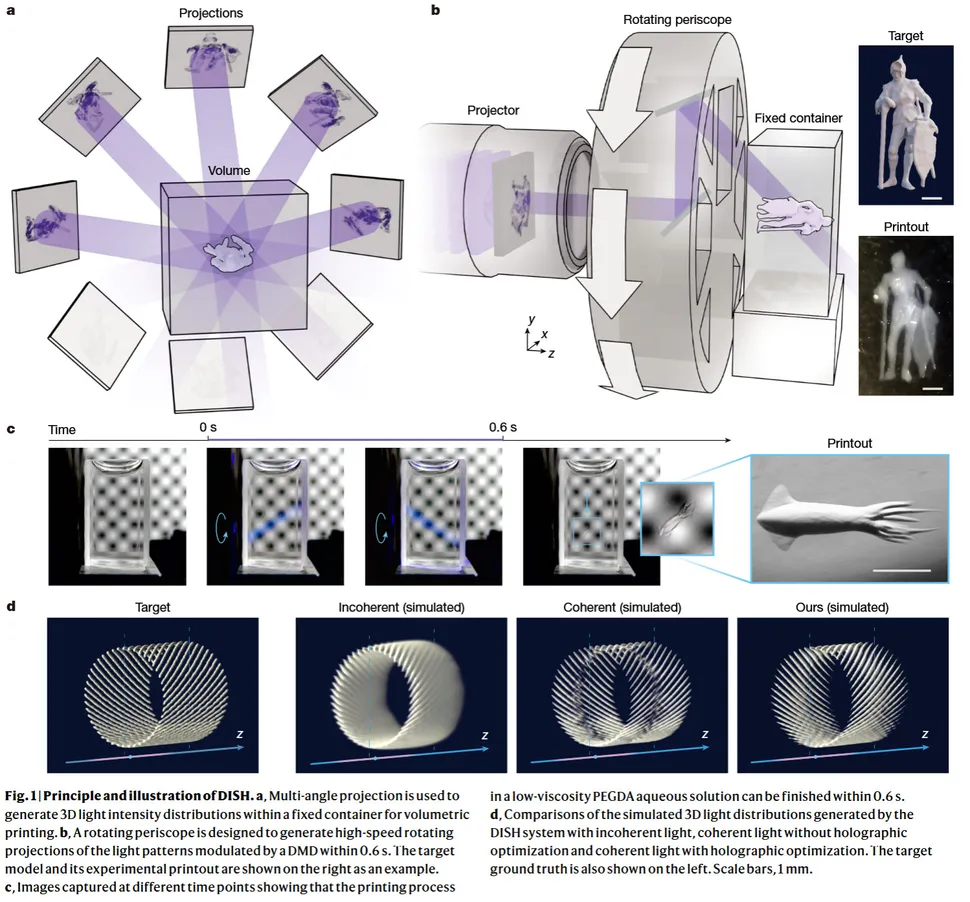

The key innovation lies in how the material is cured. Conventional volumetric 3D printing systems rotate the object while projecting patterned light through liquid resin to solidify it layer by layer. The DISH system takes the opposite approach. Instead of moving the material, it keeps it completely stationary and rotates holographic light fields around it at extremely high speed, according the study published in the journal Nature.

These precisely controlled multi angle light projections create the full three dimensional structure almost instantly. The holographic light patterns cure the resin simultaneously throughout the entire object, eliminating the need for slow layer by layer fabrication.

Tsinghua University

This approach offers not just speed, but also improved accuracy and stability. Because the material does not move during fabrication, the process reduces mechanical vibrations and alignment errors that can affect traditional systems.

The technology could have significant implications across multiple industries. The researchers say DISH is particularly well suited for manufacturing micro scale components such as photonic computing hardware, smartphone camera modules, micro robotics, and flexible electronics.

It could also enable faster production of advanced biomedical structures, including tissue engineering scaffolds and micro medical devices, where precision and speed are critical.

If the technology can be scaled for industrial use, it could dramatically accelerate manufacturing timelines for complex miniature components. Instead of hours or minutes, future factories may produce precision micro devices in seconds or less.