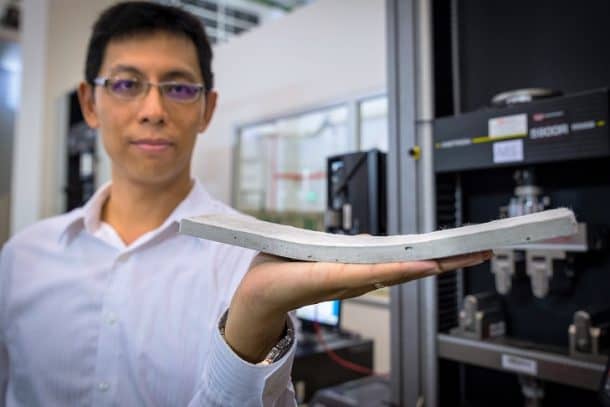

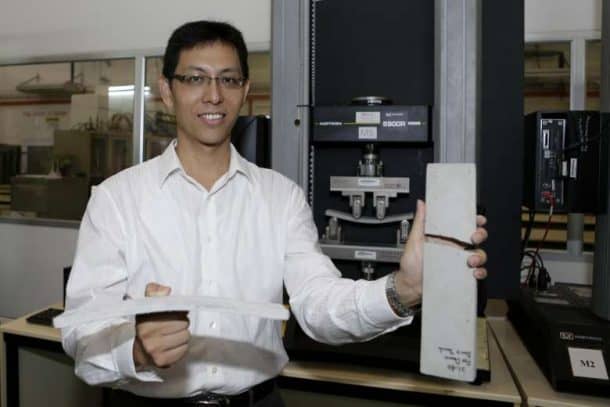

ConFlexPave is a new type of concrete invented by the researchers at the JTC Industrial Infrastructure Innovation Centre (I3C). Apart from being stronger and more durable, the most distinct aspect of this new type of concrete is its flexibility.

The scientists from the Nanyang Technological University (NTU) claim that the non-brittle structure of ConFlexPave ensures longer endurance and also cuts back on maintenance costs. Professor Chu Jian, from the JTC I³C, said that the newly developed material is ideal for the pre-fab homes:

“We developed a new type of concrete that can greatly reduce the thickness and weight of precast pavement slabs, hence enable speedy plug-and-play installation, where new concrete slabs prepared off-site can easily replace worn out ones.”

The design team believes that the ability of ConFlexPave to be moulded into sleek precast asphalt plates could reduce the construction time for roads etc. allowing more to be laid down.

How ConFlexPave Works

The conventional concrete mix comprises of cement, gravel, water, and sand. Though the mix ensures the durability of the structure, the concrete is notorious for cracking under heavy pressure. As opposed to the usual cement mixture, ConFlexPave is a unique combination of polymer microfibers and hard materials that impart strength and flexibility to the structure.

The lead researcher of the project Assistant Professor Yang En-Hua explained the idea behind ConFlexPave:

“The key breakthrough was understanding how the components of the materials interact with one another mechanically on a microscopic level. With detailed understanding, we can then deliberately select ingredients and engineer the tailoring of components, so our final material can fulfil specific requirements needed for road and pavement applications. The hard materials give a non-slip surface texture while the microfibers which are thinner than the width of a human hair, distribute the load across the whole slab, resulting in concrete that is tough as metal and at least twice as strong as conventional concrete under bending.”

The Director of the Technical Services Division, Mr. Koh Chwee applauded the great collaborative effort of the researchers for the development of this technology.

“Through collaborations with universities such as NTU in research and development of disruptive technologies, JTC hopes to pioneer cutting-edge industrial infrastructure solutions to address challenges faced by Singapore and its companies such as manpower and resource constraints. We will continue to open up more of our buildings and estates to test-bed and if successful, implement such new solutions.”

Being lightweight as compared to the traditional material, the bendable concrete will also make it easier for the construction materials to be transported to the site.

Nice Article.