Scientists at NTU Singapore have developed a novel fabric that stiffens on demand, potentially revolutionizing medical devices and soft robotics such as drone limbs. This innovative material, named RoboFabric, was created through an integration of geometric design, 3D printing, and robotic control.

The NTU research team, led by Nanyang Assistant Professor Wang Yifan from the School of Mechanical and Aerospace Engineering, has already demonstrated the fabric’s practical applications. They have developed an elbow support to help individuals carry heavier loads and a wrist support prototype that could stabilize joints, aiding patients with Parkinson’s Disease who experience trembling.

“We were inspired by how animals often have multiple functionalities for their limbs through the use of intricate structures, much like the shape-morphing and stiffness-variation in octopuses,” said Professor Wang. He envisions a future where patients needing plaster casts for fractures can opt for flexible limb supports that stiffen on demand. Unlike traditional rigid casts, these supports would be easy to put on or remove at the touch of a button.

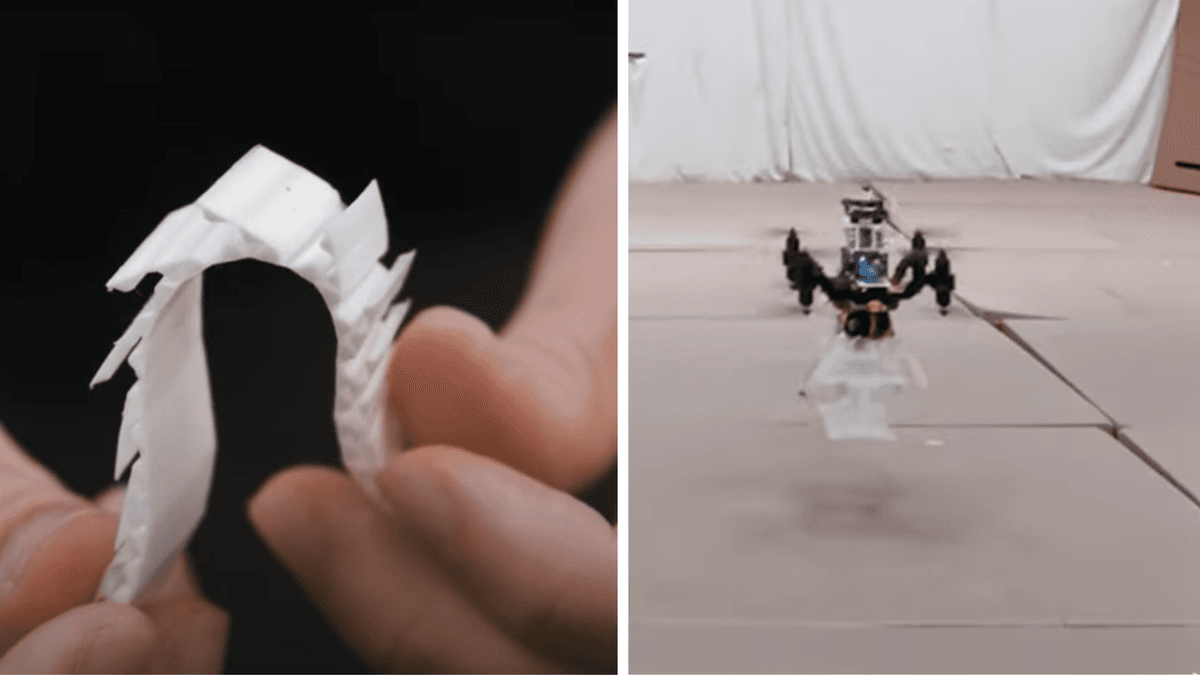

This patent-pending technology draws inspiration from the interlocking scales of pangolins and armadillos, which form protective shells. The development process begins with an advanced mathematical algorithm that designs an interlocking system of tiles. These 3D-printed tiles are connected by metal fibers running through tiny channels, or by an external soft case requiring constant negative air pressure. When these fibers contract, the tiles interlock, increasing RoboFabric’s rigidity by over 350 times and providing additional strength and stability.

The study, published in Science Robotics, also explores RoboFabric’s potential in robotics. The team demonstrated a tiny robot composed of thin, wave-shaped tiles sealed in an elastic envelope. By applying a vacuum, the RoboFabric stiffens into a designated shape, allowing the robot to climb or swim, carry small loads, and protect fragile items by forming a rigid shell. This capability is crucial for exploration and rescue robots, which must navigate complex terrains and provide protection on demand.

Prof Wang’s team believes RoboFabric’s unique properties will pave the way for advanced applications in both medical and robotic fields.