Researchers at the Singapore University of Technology and Design (SUTD) have unveiled a groundbreaking advancement in 3D food printing, introducing 3D-printed edible QR codes for tailored meals. This innovation paves the way for personalized, visually appealing, and nutritionally tailored meals, potentially revolutionizing food consumption, particularly for individuals with specific dietary needs or swallowing difficulties.

“To date, there is a lack of an efficient approach to printing multiple food inks with different rheological properties,” stated the study. The SUTD research outlines a novel technique enabling the seamless printing of foods using multiple ingredients. This new method performs multi-material 3D food printing using a single nozzle with multiple inlets and rapid pneumatic switching of printing materials.

“Printing food in 3D enables the customization of nutrients, the creation of aesthetically pleasing meals, and the modification of food texture to suit individual dietary needs,” explained Associate Professor Michinao Hashimoto, the principal investigator of the research. Previous 3D food printing techniques often resulted in fragmented prints and required complex machinery. The team’s approach, drawing inspiration from microfluidics, uses a dual-inlet, single-outlet system. This innovative design allows for the combination of different food “inks” before printing, eliminating the need for multiple nozzles and the associated challenges.

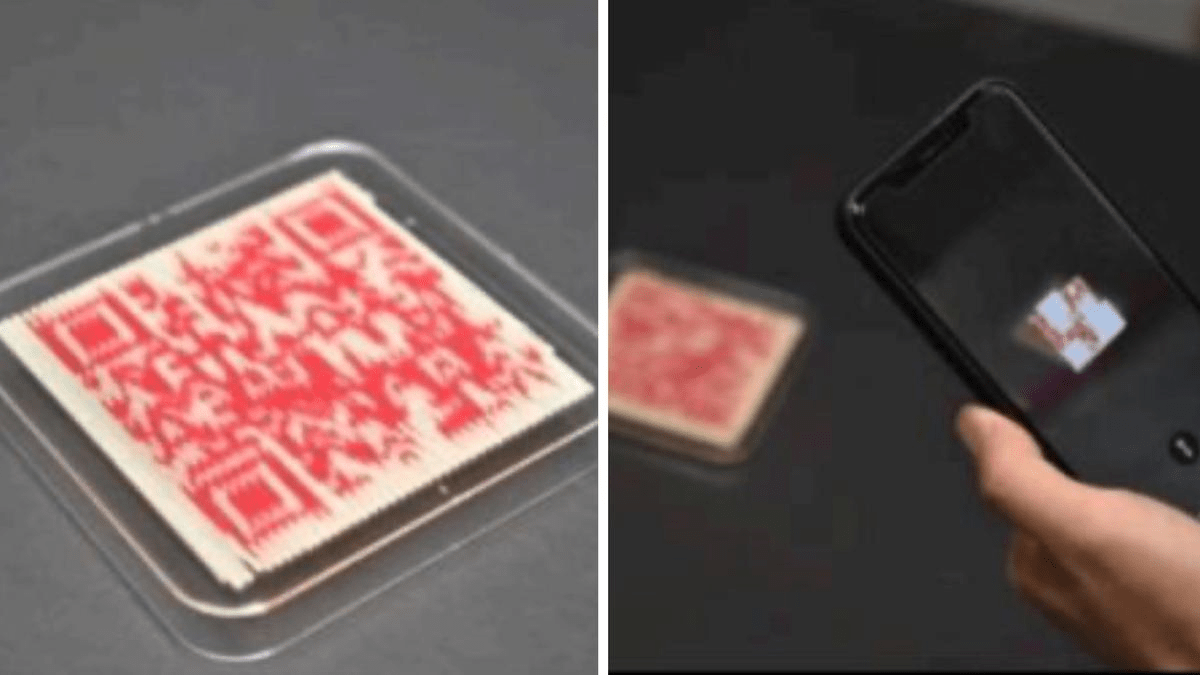

“Existing methods for multi-material food printing rely on independently controlled syringes, posing challenges in aligning more than one type of food inks and creating a seamless continuous food filament with different materials,” the study highlighted. The researchers successfully demonstrated their system by printing the SUTD institutional logo and a fully functional QR code using different milk inks.

This breakthrough technology addresses a major hurdle in 3D food printing: achieving smooth transitions between ingredients with varying properties, such as viscosity. “The overall objective of this project was to develop a method for multi-material 3D food printing with different viscosities,” the researchers expressed. The SUTD team’s design includes a widened exit outlet and an offset printing algorithm, effectively resolving this issue.

Additionally, the ability to incorporate repurposed food sources, such as okara or insect protein, into visually appealing meals could promote sustainability and reduce food waste. The researchers aim to refine their technology further, accommodating more inlets and scaling up for commercial applications.

“Our technology can be used to 3D-print foods consisting of multiple materials without compromising the printed structures and appearance,” said Dr. Lee Cheng Pau, the lead researcher. This technology opens up a world of possibilities, from crafting personalized meals to designing visually stunning dishes, even allowing for the creation of interactive dining experiences, such as incorporating edible QR codes that provide diners with detailed information about the ingredients and nutritional value of their meals.