People living in Pakistan know what it feels like sitting through the hot summer without electricity. Most of the households have a generator or a UPS (Uninterruptable Power Supply) but these devices often malfunction. A new technology developed for fans that reduces the running cost can help with the situation.

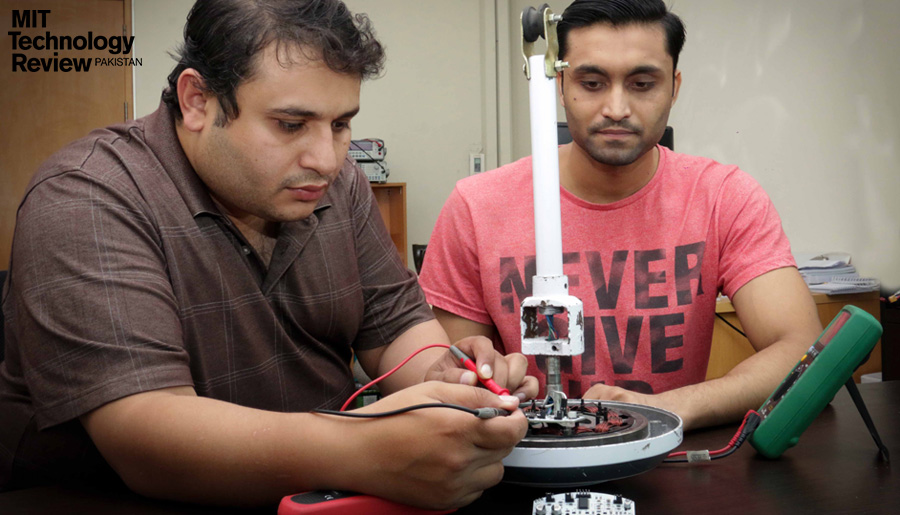

Dr. Tauseef Tauqeer from Information Technology University (ITU) in Lahore started working on the technology when he was at the National University of Sciences and Technology (NUST). He continued his research even after he shifted universities and received the first order of 1000 fans for an industry in Pakistan a year and a half ago.

The new variant for the fan uses Brushless DC (BLDC) drive that consumes less power than the fans normally installed in the houses. These fans normally use 80 to 100 watts of electricity while the new technology only consumes 32. This results in a great decrease in electricity bills without compromising on the speed.

The electricity in Pakistan has periods of sags and swell and the voltage is not always the desired 230 volts. This not only affects the performance of the fans but also damages the machinery. In some cases, it is damaged beyond repair. The new variant of the fan maintains the normal voltage level irrespective of the voltage being supplied by the grid.

The fan requires a battery bank. This is already installed in the houses with a UPS and it is charged through the main grid which makes the fan work during power outages. A small battery can also be attached to the fans. The battery can also be charged by solar panels. This is a one time cost but saves much on the bill in the long run.

“Our main competitors are Chinese fans which have similar features and technology,” says Dr. Tauqeer. “But they are much more expensive and are not customized according to our region. As a result, their air delivery is less and the size is smaller.”

These fans can be repaired locally as well as all the components are made here. The problem with Chinese fans is that their parts are not easily available. The Chinese fans also cost more and these fans cost less than half of their $120. They cost only $50.

“If Pakistan’s manufacturing industry starts making fans with this technology, more than 1000 GWh energy can be saved per year, which is 3.5% of domestic use currently,” says the doctor. It can definitely be something good for the country that suffers from power shortage.