A metal’s new type has been demonstrated recently by researchers that is so light that it can float on water. The material has been termed as metal matrix composite and was developed in collaboration with US Army. The applications? Imagine a boat built of this material. Now imagine this boat not sinking even after taking considerable damage – get the picture?

The material also hopes to enhance automotive fuel economy since it is pretty heat resistant while being light weight. Syntactic foams have been into play for quite some years now, however, this qualifies as the first development of a metal matrix syntactic foam that is lightweight. Nikhil Gupta, an NYU School of Engineering Professor in the Department of Mechanical and Aerospace Engineering and study’s co-author said, “This new development of very light metal matrix composites can swing the pendulum back in favor of metallic materials. The ability of metals to withstand higher temperatures can be a huge advantage for these composites in engine and exhaust components, quite apart from structural parts.”

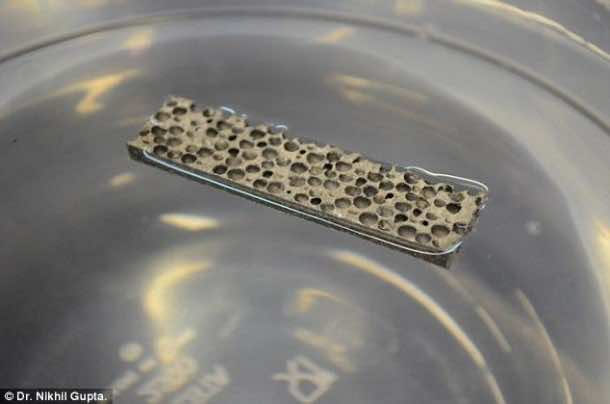

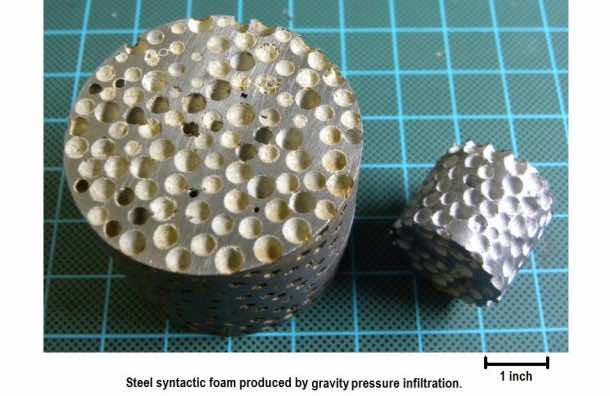

It has been created by Deep Springs Technology and the New York University Polytechnic School of Engineering. The magnesium alloy matrix composite has been enhanced by making use of silicon carbide hollow particles and exhibits a density of 0.92 grams per cubic centimeter, in comparison water has a density of 1g/cc. Apart from being less dense than water, it also is capable of surviving the rough conditions offered by the marine environment. As per the team, it will be ready for prototyping in 3 years’ time.

The amphibious vehicles, for instance the Ultra Heavy-lift Amphibious Connector (UHAC) that is being developed by the US Marine Corps, will be benefitting greatly from the high buoyancy and the low weight which is offered by syntactic foams.

The applications of this new material are limitless and soon we shall be witnessing this material making its impact in the market.