Researchers have made a breakthrough in lithium-ion battery (LIB) technology by developing an innovative approach to solid-state electrocatalysis. Led by a team from the University of Science and Technology of China, the new design features an advanced sulfur-doped black phosphorus (S/bP) anode, which, when paired with a lithium cobalt oxide (LCO) cathode, allows for rapid recharging of the battery.

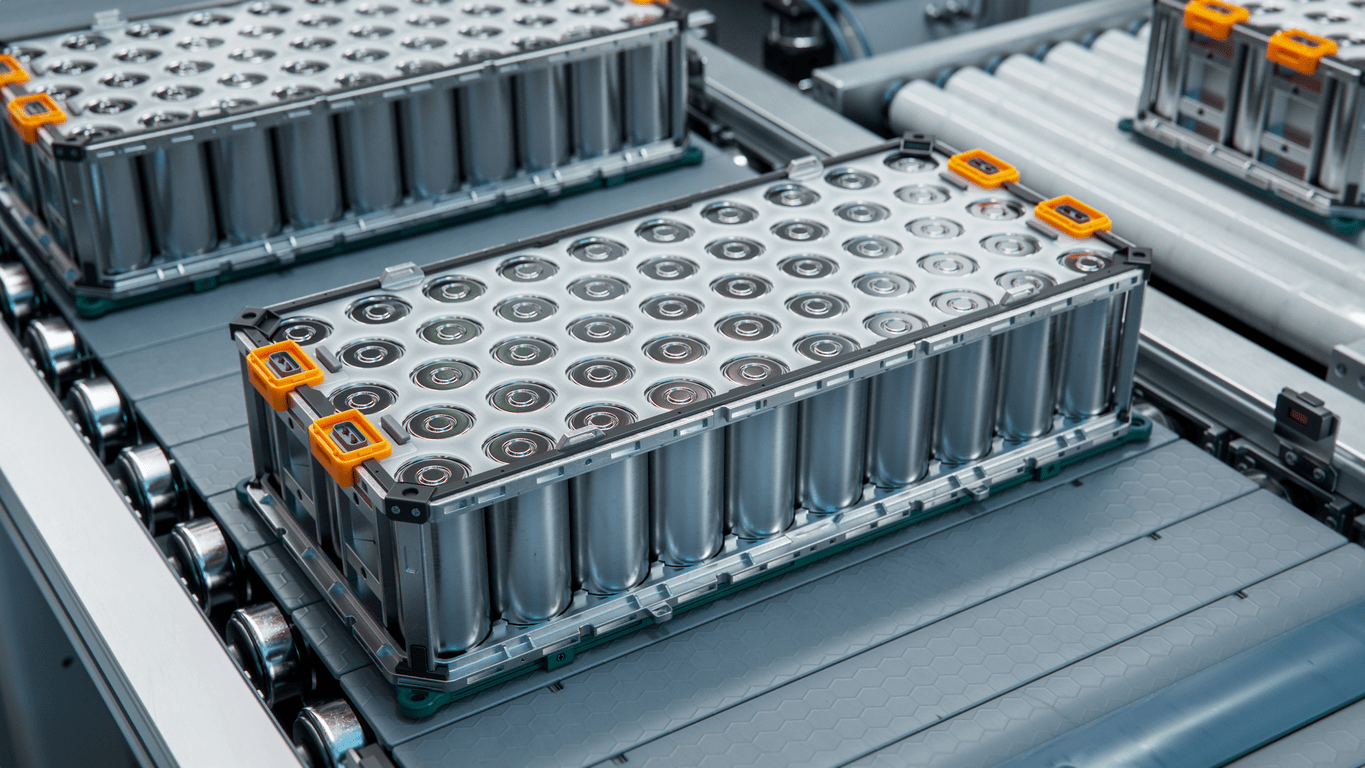

The result is an energy-dense lithium-ion battery that can achieve an 80% charge in just nine minutes, outperforming earlier designs in terms of both speed and efficiency. With an impressive energy density of 302 Wh kg?¹, the battery maintained this performance for over 300 charge cycles, demonstrating its durability and commercial viability.

At the heart of this achievement lies the application of electrocatalysis to solid-state reactions. Electrocatalysis accelerates electrochemical reactions by lowering the energy barrier, and it is a fundamental mechanism in fuel cells, batteries, and other energy conversion technologies. Traditionally, electrocatalysis has been confined to liquid-solid or gas-solid interfaces, but this breakthrough demonstrates its potential in solid-phase reactions, a critical need for the advancement of LIBs.

The research team addressed a common limitation of LIBs: the sluggish movement of lithium ions in solid anode materials such as silicon and phosphorus. Typically, these materials store lithium ions through alloying reactions, but their slow ion mobility limits the battery’s ability to recharge quickly. Additionally, the products of the lithium-alloying process exist in solid phases, bypassing the typical two-phase contact necessary for traditional electrocatalysis.

To overcome these challenges, the team employed heteroatom doping—a process where foreign atoms are integrated into the material’s structure to alter its properties. In this case, sulfur was introduced into black phosphorus to improve conductivity and enhance the reaction kinetics of the Li-alloying process. By using a critical heteroatom doping concentration of approximately 5%, the researchers were able to create highly active sites for alloying reactions. These sites significantly boosted the breaking of intrinsic chemical bonds, facilitating the formation of smaller unit cells that increased the number of reactive sites, ultimately speeding up the electrochemical reaction.

“Electrocatalysis is crucial in enhancing the efficiency of reactions in batteries, and in this study, we’ve shown that it can be applied to solid-state reactions with tremendous success,” the team stated. “This breakthrough enables the development of ultrafast-charging batteries that are not only faster but also more energy-efficient than current designs.”

The result of this innovation is a battery that recharges 80% of its capacity in just nine minutes, far exceeding the capabilities of earlier LIBs. This performance makes it ideal for high-energy applications and marks a significant step forward in the ongoing quest for faster and more efficient battery technology.

Moreover, the team’s findings suggest that further improvements can be made by refining the doping process and optimizing the reaction environment. According to theoretical predictions and X-ray absorption spectroscopy (XAS) data, heteroatom doping at the correct concentration accelerates the Li-alloying reactions, boosting overall performance.

In addition to speeding up the charging process, the new design minimizes the battery’s environmental impact. The improved reaction kinetics reduce energy consumption during charging, making the battery not only faster but also more sustainable.

The researchers believe that this innovative approach to electrocatalysis in solid-state reactions will have far-reaching implications for the future of energy storage technology.

“This study advances the field of solid-state electrocatalysis and brings us closer to the goal of high-energy, fast-charging batteries suitable for widespread industrial use,” the team concluded.