BMW Group, on their Digital Day 2018 event, displayed innovative technology applications that would change the future for the automotive industry. 3D printed motorcycle frames were featured among these. Although 3D printing technology has been put to produce car parts, concerns were raised about the appearance of the motorcycle frame.

Frontline technological innovations, on which BMW is currently working on, were displayed at the BMW Group Digital Day 2018 event. The theme of the event was certainly predictable as it revolved around information technology and included topics like the use of artificial intelligence in autonomous cars, designing and developing 5G mobile service, how the development processes are rapidly improving through mixed reality applications, connecting software operating systems for cars with vehicles. Along with these, there was an area designated to 3D printing technology.

BMW has been investing heavily in the research and development of 3D printing technology. It has already produced 140,000 parts per year for a number of departments of the Group, through its Research and Innovation Center in Munich.

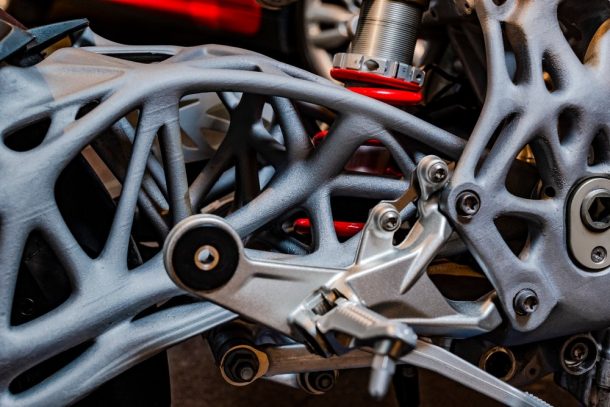

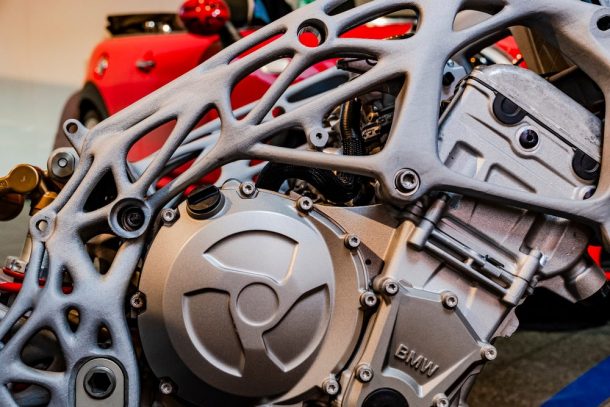

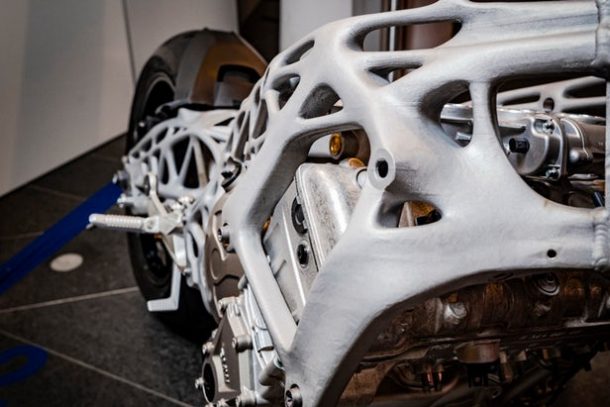

The wide range of parts produced include anything from aluminum mountings for the soft roof of the i8 Roadster and BMW’s DTM racing cars fuel pump to cosmetic plastic bits for customized Minis. Nonetheless, it would be appropriate to say that a 200-hp S1000RR motor in a 3D-printed frame and swingarm takes things to another level.

BMW Motorrad has never been shied away from innovation. However, BMW did not elaborate on the 3D printed motorcycle frames and left it up to the viewers’ imagination to what they might signify and more importantly what it is made of.

According to BMW, the 3D printed motorcycle frames or all vehicle parts, in general, are a faster and cheaper way of production. We will have to wait for an official statement from BMW about what this signifies and what we might expect in the future.