A cutting-edge air-based refrigeration system developed by the Korea Institute of Energy Research (KIER) may reach temperatures as low as -76°F (-60°C) without the use of hazardous refrigerants. Gases that contribute significantly to global warming, such Freon and hydrofluorocarbons (HFCs), are no longer required thanks to this innovative technique.

The vapor compression cycle, which employs refrigerants like hydrochlorofluorocarbons (HCFCs) and chlorofluorocarbons (CFCs) to cool by absorbing heat during the evaporation of liquid refrigerants, has been the backbone of most cooling systems for decades. These gases are useful, but because of their enormous potential for global warming, they have serious negative effects on the ecosystem.

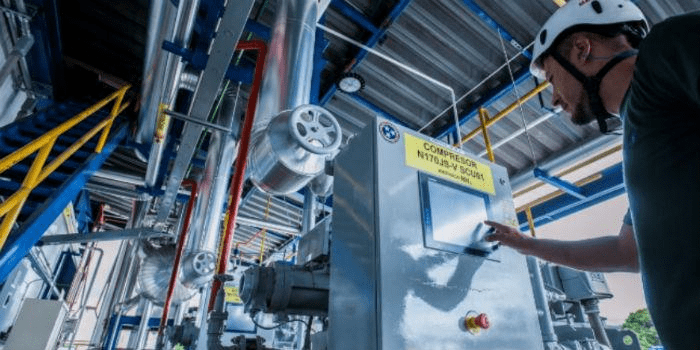

The KIER eco-friendly cooling is based on the reverse-Brayton cycle, where the working fluid is air. It involves the process of air compression coupled with heat exchange and expansion resulting in low-grade temperature gas without any liquid refrigerants. This is possible to provide by a newly introduced component termed as the “compander,” that manages to fit both a compressor and an expander into a single 4-sided rotor, operational at ultra-high speeds. More so, due to tolerances smaller than 0.1 millimeters between some parts, it can cool down large volumes of air very fast and effectively.

The system’s performance is exceptional, reaching -76°F in just one hour, and it has the potential to achieve even lower temperatures of -148°F (-100°C). This represents a 50% efficiency improvement over traditional vapor compression systems.

The KIER team is working on further improvements to the system, with potential applications in semiconductor manufacturing, pharmaceuticals, and biotechnology. As global regulations on harmful refrigerants tighten, such as the European Union’s phase-out of F-gases by 2025, this new air-based refrigeration system could be a game-changer for industries requiring ultra-low temperatures.