In a major leap forward for battery safety, LG Chem has developed a material called Safety Reinforced Layer (SRL), which offers a proactive way to halt battery overheating before it leads to fires or explosions.

Thermal runaway has long been a critical challenge in the battery industry, particularly for devices powered by lithium-ion batteries. It occurs when the battery’s internal components specifically the cathode and anode come into direct contact, resulting in a short circuit and rapid temperature rise.

According to LG Chem’s press release, “Thermal runaway occurs when the cathode and anode inside the battery unintentionally come into direct contact, causing a short circuit and generating heat. Within seconds, the temperature can rise to nearly 1,000°C (1,832°F).”

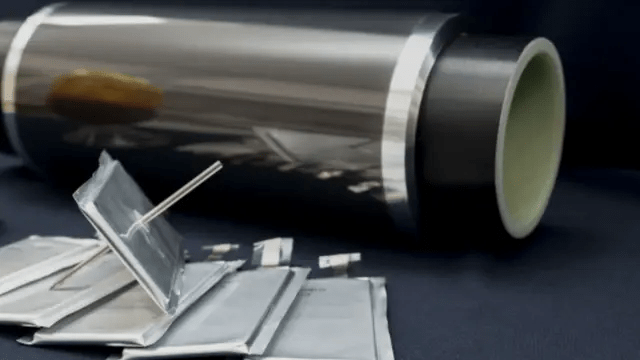

To address this hazard, LG Chem has introduced SRL, a thin, temperature-responsive material designed to act as a barrier within the battery. Measuring just 1 micrometer thick—approximately one-hundredth the thickness of a human hair—SRL is placed between the battery’s cathode and its current collector, which is typically an aluminum foil that conducts electricity. The key innovation here is that SRL allows normal electrical flow under typical conditions but reacts quickly to rising temperatures by altering its molecular structure.

“When the battery’s temperature rises beyond the normal range, between 90°C and 130°C, the material reacts to the heat, altering its molecular structure and effectively suppressing the flow of current,” explained LG Chem’s research team.

This responsive behavior halts the thermal runaway process in its early stages, preventing further escalation.

Additionally, SRL is highly sensitive to temperature fluctuations. “The material’s electrical resistance increases by 5,000 ohms (?) for every 33.8°F (1°C) rise in temperature,” LG Chem noted.

This significant rise in resistance, which can become over 1,000 times higher than under normal conditions, cuts off the flow of current, stopping the overheating in its tracks. Notably, this safety feature is reversible; once the temperature returns to safe levels, the resistance decreases, and the battery resumes normal function.

LG Chem’s SRL has been rigorously tested to validate its effectiveness. In nail penetration tests—designed to simulate physical damage to mobile lithium cobalt oxide (LCO) batteries—none of the SRL-equipped batteries caught fire, whereas only 16% of standard batteries remained fire-free. In another round of tests involving nickel cobalt manganese (NCM) batteries used in EVs, a weight impact test was conducted. While all standard batteries ignited, 70% of those equipped with SRL did not catch fire. Even the few that did only experienced brief flames that extinguished quickly.

“Impact testing on 3.4-Ah pouch cells shows that the SRL reduces battery explosions from 63% to 10%,” LG Chem researchers stated in their findings.

The development of SRL was the result of a collaborative effort between LG Chem’s Platform Technology R&D team and the Department of Battery Engineering at POSTECH, led by Professor Lee Minah. LG Energy Solution, the company’s battery storage division, also contributed to the safety verification process.

A major advantage of SRL is its seamless integration into existing production lines. The material can be mass-produced using roll-to-roll technology at a rate of 3 miles (5 kilometers) per day, making it viable for large-scale manufacturing.

“This is a tangible research achievement that can be applied to mass production in a short period,” said Lee Jong-Ku, CTO of LG Chem.

The company plans to continue testing SRL in larger-capacity EV batteries throughout the next year, having already completed safety verification for mobile batteries.

With this innovation, LG Chem aims to enhance the safety of electric vehicles and solidify its position as a leader in the battery industry. “We will enhance safety technology to ensure customers can use electric vehicles with confidence and contribute to strengthening our competitiveness in the battery market,” Jong-Ku added.