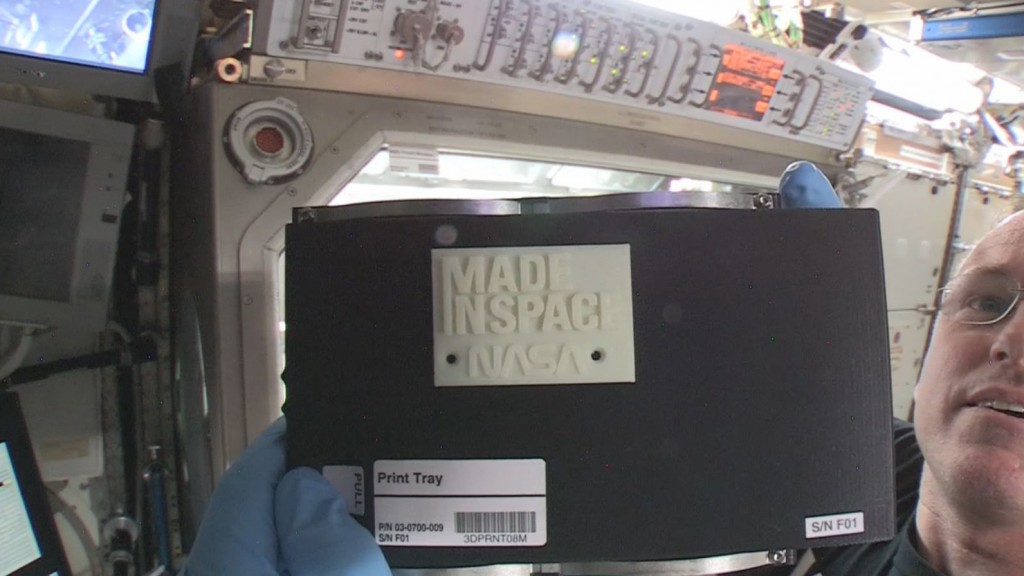

The first 3D printer in space aboard the ISS (International Space Station) printed the first object ever with the embossed faceplate reading, “NASA and Made in Space, Inc.” This feat constitutes the first step of the efforts that NASA is doing in order to enable the production of spare parts in space and work towards a simpler mission logistics. The 3D printer currently at ISS was created by ‘Made in Space’ and employs a low-temperature plastic filament to model objects, tackling one layer at a time. It has been modified so that it can work without gravity while meeting the safety standards of the space station.

The demonstration was executed by Barry ‘Butch’ Wilmore, a NASA astronaut. He is the Expedition 42 commander. On 17th November, Barry took the printer out of storage, installed it and then ran tests for 3 days that catered to the calibration of the machine with the help of mission control. NASA said that the process was controlled by the NASA team on ground thus enabling the station crew to perform other tasks.

Mission Control initiated the first actual printing job when the command was executed on November 24th, making a faceplate for it’s extruder casing. According to NASA, this not only demonstrated that the printer functioned in Zero G, but that it could create its own spare parts. Though the print of the first 3D object was successful, the object stuck to the tray, may be due to the microgravity environment. This was not anticipated and NASA says that this effect will be studied further.

The ultimate goal of the experiment was to determine the feasibility of 3D printing in space as a way of creating replacement parts with a supply of digital printing files and raw materials to fabricate objects as needed. To achieve this, the ability of the printer to develop replacement parts for itself or for another printer is a key capability. As the calibration tests continue, NASA is planning to fine tune the process. In the meantime, the objects printed in space will be brought back to Earth to compare them in detail, with those in control environments produced by an identical printer on the ground.

“The operation of the 3D printer is a transformative moment in space development,” Aaron Kemmer, chief executive officer of Made In Space said. “We’ve built a machine that will provide us with research data needed to develop future 3D printers for the International Space Station and beyond, revolutionizing space manufacturing. This may change how we approach getting replacement tools and parts to the space station crew, allowing them to be less reliant on supply missions from Earth.” Check out the video below for more details: