BAM is an incredible material that makes components many times more durable, is the slipperiest material in the world – slipperier than Teflon even! – and is almost like a diamond in hardness.

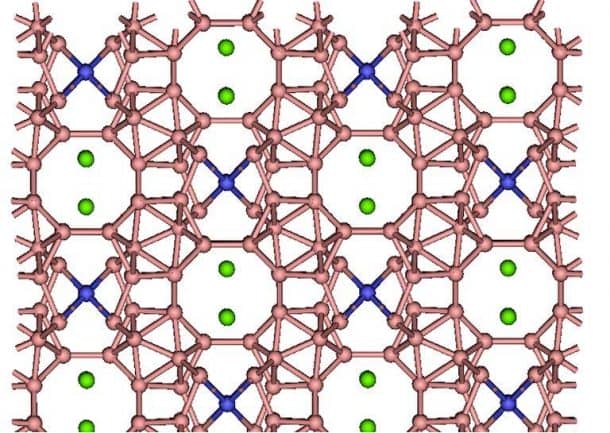

What is it made of? Well, it is made up of Aluminium, Boron and Magnesium (AlMgB14) along with titanium boride (TiB2) resulting in a substance that is just the third hardest material in the world coming after diamond and cubic boron nitride. This material named BAM (after B, Al and Mg first alphabet) was discovered by the US Department of Energy Ames Laboratory. BAM was formed accidentally in 1999 as experiments were conducted to create a substance that could convert heat energy into electrical energy.

Uh, no. BAM does not have that property but it has other characteristics like super hardness and extremely reduced coefficients of friction (meaning high slipperiness) owing to its unique chemical composition. As it turned out, this material became the world’s best lubricant.

“Its hardness was discovered by accident. We had a terrible time cutting it, grinding it, or polishing it,”

Says a materials scientist Alan Russell, of Iowa State University in Ames.

The accident turned into a benefit as the lab was given $3-million to develop and work on the new material into a substance that could considerably increase the resilience of the material and efficiency of energy. The coefficient of friction for Teflon is 0.05, previously making it the slipperiest material. However, BAM has a coefficient of friction of 0.02 that is even less than half of Teflon’s thus winning the title of the slipperiest material on earth.

BAM has many applications as a micro layer of its coating can provide a surface enhanced durability and more efficient energy. Bruce Cook, the principal investigator of the Ames Lab experiment, estimated that use of BAM could “save US industries 330 trillion kilojoules or 9 billion kilowatt-hours each year by 2030 – translating into about $179 million of savings a year.”

Materials engineers would know that usually a substance can exhibit either the property of hardness or of low friction/ slipperiness. Both these characteristics in a single material is an entirely novel phenomenon. Therefore, BAM’s physical properties are being studied thoroughly at present, as it is unclear why the material possesses such capabilities.

Frictional wear is an engineer’s biggest fear as friction causes wear and tear in machines, wastes a lot of energy and adds another layer of complexity to designing machines. Now, BAM has the potential to solve that problem as it has a low coefficient of friction but still maintains its strength. BAM can significantly reduce the tension as it is super slippery and super hard. This will help save useless energy expenditure and increase the longevity of machines beyond imagination.

What do you think of BAM? Do you think it can be used as a potential material in mechanical, materials and robotics engineering? Let us know what you think!

Its not the cost, we can find ways to make it cheap. Companies don’t like the idea of a product that lasts forever, because then there is no need to ever buy another.

This would be a good coating for cams in IC engines. All Lycoming aircraft engines suffer from high cam wear. and last the life of the engine. This coating would be a good solution.

id like to know why this is so expensive?

\

How do you know how much it costs? Where to buy it?

get cast iron works even better and lasts forever if cared for till then

This is a discovery of truly historic importance. I am concerned that there are not many more current examples of practical use in commercial products. It should have potential for Class 8 truck fifth wheels, ball bearing replacement with BAM treated plain bearings and shafts, lab instruments, The applications seem endless. Why are there so few applications years after the discovery of BAM?

Sounds like grear stuff. So, when will they start making pot & pans out of it so I can throw away all my scratched up Teflon ones? 🙂