An idea to colonize the planets other than our very own Earth was considered to be a science fiction once. But now, aerospace companies like Mars One and SpaceX are opening doorways to make human colonies on Mars as well. A trip to Mars is not that much of a big problem. Our biggest concern is to ensure a successful life on Mars and that forces us to reinvent all the ways of life to suit that particular environment. High-tech research is being conducted to develop the materials that can sustain life on the Martian soil. Recently, the engineers from Jacobs School of Engineering of the University of San Diego were able to make the bricks of Martian soil using NASA’s funding. The research findings were published in Nature.

The researchers used simulated Martian soil (with known compositions) to create the strong bricks using minimal resources. Use of Martian soil to build human habitats is not a new idea, but this research is quite unique. These bricks do not require a brick kiln or complex chemical composition to convert organic compounds into the binding polymers.

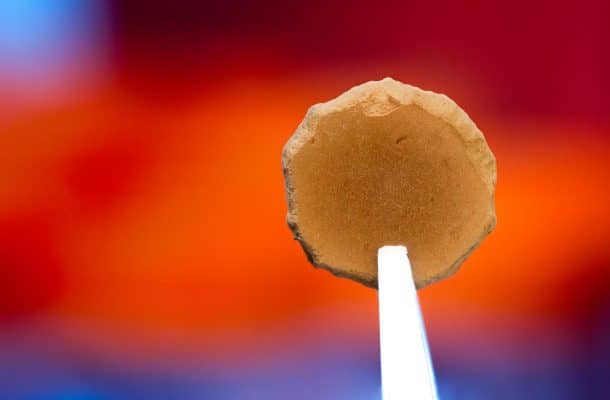

Originally, the researchers aimed to reduce the number of binding polymers in the material. However, they soon discovered that no polymer was required at all to make a brick from Martian soil. The Martian soil simulant called Mars-1a is used to make a brick in a two-step process that requires no heating or additives. First, the stimulant is added to a flexible mold by using a rubber tube. A pressure equivalent to the drop of a 10-lb hammer from a height of one meter is then applied to the soil. The high pressure results in a small round brick, which can be cut into square shapes as required.

According to the researchers, the reddish hue is imparted by nanoparticulate iron oxide (npOx), which serves as the binding agent in the brick. The team performed a series of scans on the material to discover its structure and found out that the larger rock basalt particles are coated with nano iron particles. The smooth facets of these nanoparticles result in easy binding under high pressures.

The leader of this research team, Yu Qiao, who is also a professor of structural engineering at UC San Diego, says,

“The people who will go to Mars will be incredibly brave. They will be pioneers. And I would be honored to be their brick maker.”

There have been numerous other attempts for the creation of materials that may improve the inhibition of humans on the planet. However, this one is the most incredible of all, as this material even surpasses the strength of steel-reinforced concrete. The engineers say that this method can be applied to the additive manufacturing by building a layer of soil and then compressing it. Like the usual 3D printing methods, the procedure will be repeated recursively, until the desired structure is created. The bricks produced so far are smaller in size, and the team plans to make bigger ones soon.

Aerospace companies are in a race to colonize Mars very soon. President Trump even signed a Congress bill as an official promise that it will happen by 2033.

In all excitement, we must not forget a few things. First, the brick is made with simulated Martian soil and not the real one. So we do not know about the behavior of the actual soil. Second, the iron bonding agent is quite common in the Martian soil, but it is not present in all of it. So, only some areas of the planet may be feasible for building such structures. Whether this structure serves useful for the future Mars colonies or not, we shall have to wait and see.