Lexus is changing the game in car manufacturing with its upcoming electric cars. They’ve introduced a “self-driving assembly line” at the Japan Mobility Show, signaling a significant shift away from traditional assembly line methods that rely on conveyor belts.

The most eye-catching display at the event was the LF-ZC, an angular electric concept car set for a 2026 release. While concept cars often generate hype and skepticism in equal measure, the real innovation lies in the manufacturing process Lexus is adopting.

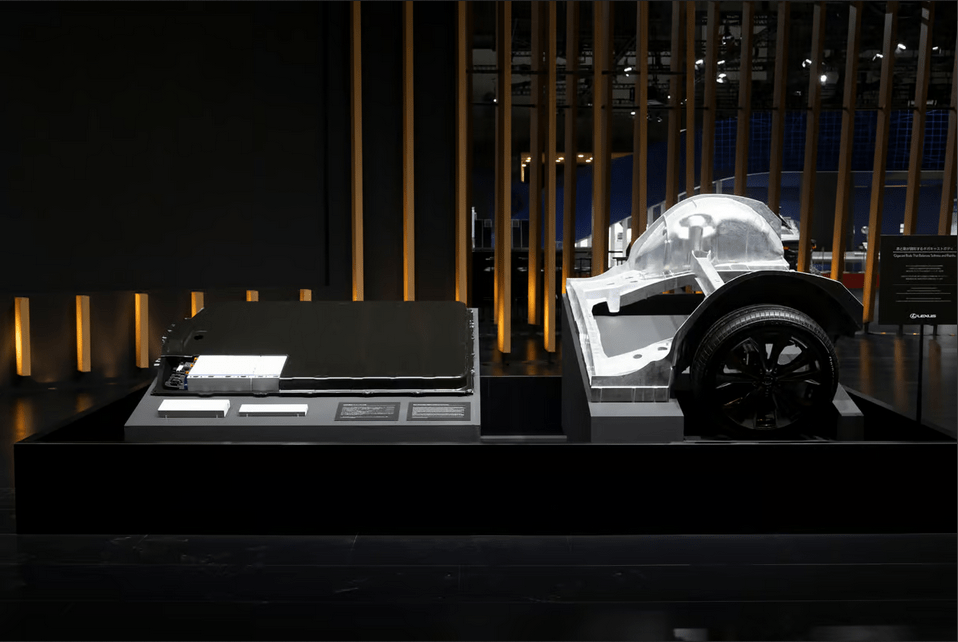

Lexus’s new electric cars will be built around a self-driving production line. These vehicles will have a unique chassis constructed from three parts using “gigacasting.” When these pieces come together, along with the installation of essential components like batteries, motors, wheels, and “wireless terminal components,” the car can autonomously navigate the rest of the production process. This means that conveyor belts, which have been a staple of car assembly lines for decades, become redundant.

What’s particularly exciting about this approach is the flexibility it offers. Since the chassis can be adapted for various body types, Lexus can configure the production stations differently for each model. This means a more efficient and versatile manufacturing process that can adapt to different car designs.

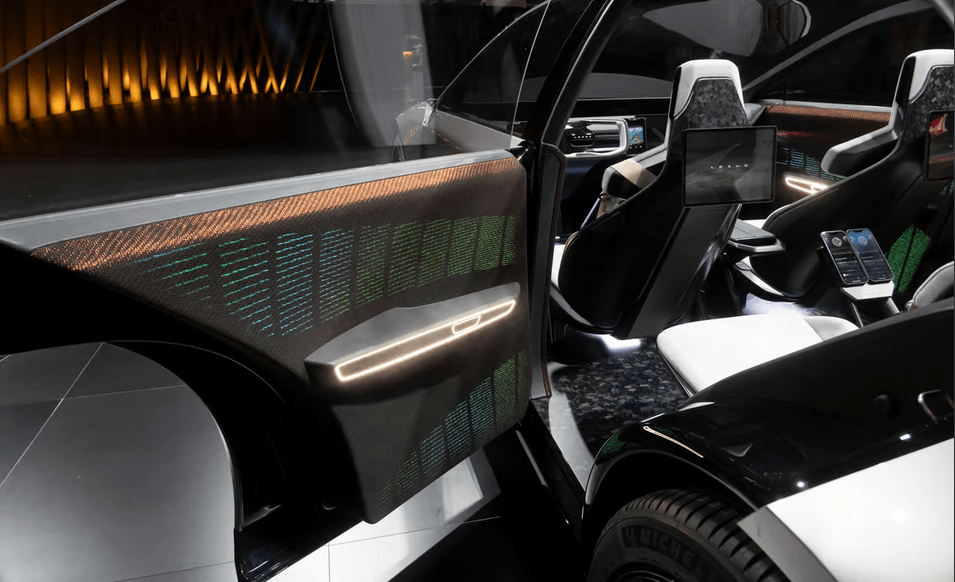

The LF-ZC itself boasts some impressive features, such as a steering-by-wire system, an AI voice interface akin to conversing with a helpful butler, and high-performance batteries aiming for double the range of conventional electric vehicles.

Perhaps the most intriguing aspect is the car’s ability to replicate various driving characteristics, sounds, and vibrations, tailored to individual preferences. It even allows for gaming, with players using the car’s controls as game controllers and then transferring that experience to the real road.

While concept cars have a history of being more about showmanship than substance, Lexus’s new production method steals the spotlight. It combines advanced technology with practical efficiency, setting a new standard for how cars are assembled.

Lexus’s transition to a self-driving production line not only marks an innovative approach in car manufacturing but also promises to streamline the process, reducing the need for traditional conveyor belts and providing a flexible platform for producing a variety of electric vehicles.