Apple’s strategy to reduce its dependence on China has caught global attention, particularly with the increased visibility of iPhones being assembled in India. Reports now suggest that a number of these devices sold in the U.S. originate from Indian facilities.

Over the past two financial quarters, Apple CEO Tim Cook has emphasized that iPhones sold in the United States are being assembled in India. On the surface, this change suggests a diversification of Apple’s manufacturing footprint and a push to reduce reliance on China. However, as Patrick McGee, Financial Times reporter and author of Apple in China: The Capture of the World’s Greatest Company, points out, the story doesn’t end at final assembly.

According to McGee, although the finishing touches on iPhones are now handled in India, the devices remain inextricably tied to Chinese manufacturing. “These iPhones are as dependent on the China-centric supply chain as every iPhone you’ve ever held,” he says. His commentary sheds light on a crucial yet often overlooked fact: the production of an iPhone involves thousands of intricate components, most of which are machined, fabricated, and assembled within China.

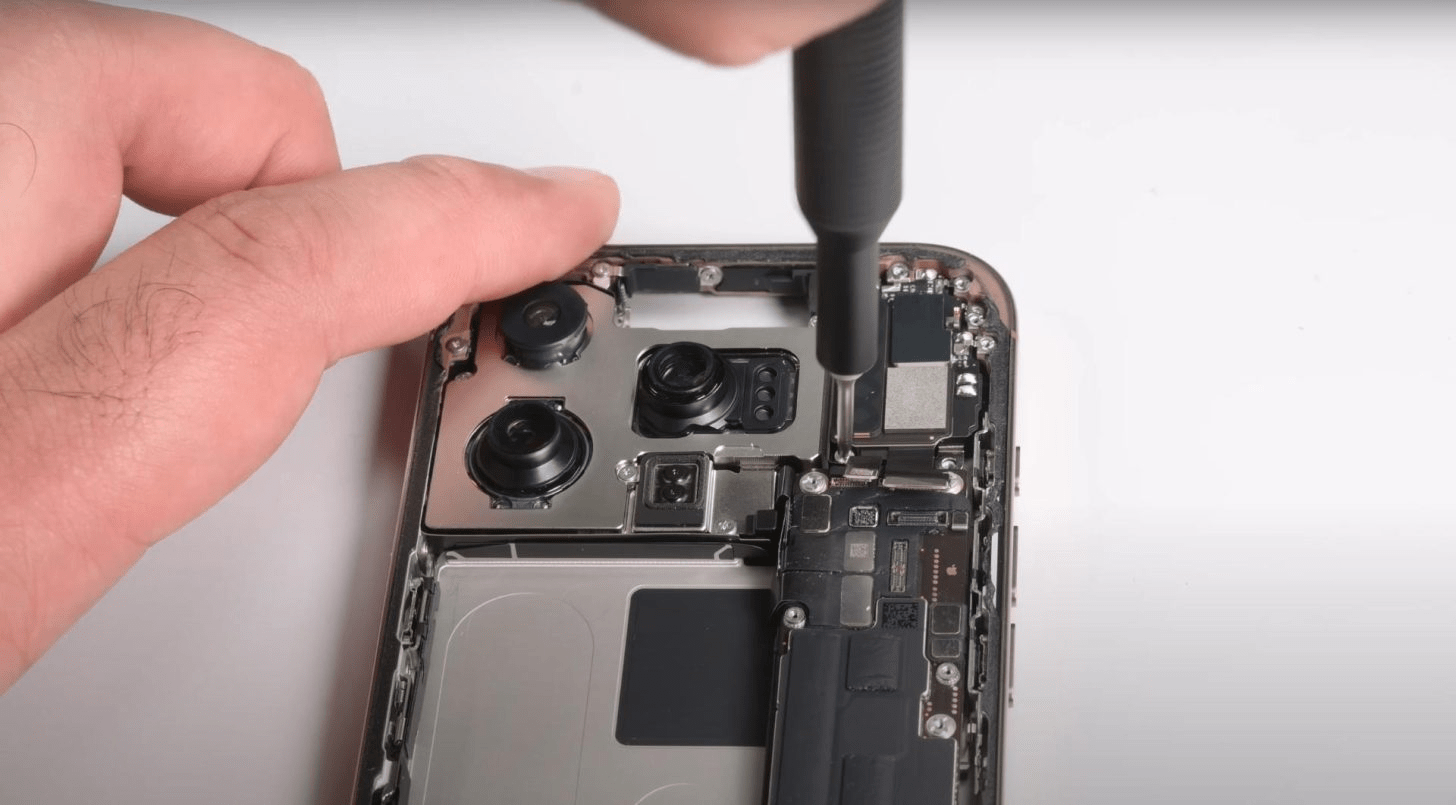

Each iPhone comprises roughly 1,000 tiny parts from semiconductors and sensors to haptics modules and display components that are processed through a sprawling network of Chinese suppliers and subcontractors. This supply chain employs as many as three million workers annually, supported by an infrastructure that has taken decades to build and optimize. Only after this elaborate process are the subassemblies shipped to India, where the final assembly and packaging take place.

McGee underscores that while this last step qualifies as a “substantive change” under trade laws allowing Apple to avoid tariffs in both the U.S. and Indian markets the broader manufacturing ecosystem hasn’t actually relocated. The logistical, financial, and political hurdles in attempting to replicate China’s capabilities elsewhere make such a shift a long-term, uncertain prospect. “Maybe, and hopefully, it will [shift],” McGee notes, “but that would take years, cost tens of billions of dollars, and cause Apple unwanted friction with Beijing and Chinese consumers.”

Bloomberg’s Mark Gurman adds to this skepticism, stating plainly that relocating iPhone production to the U.S. is essentially impossible. The cost and complexity of such a move are so prohibitive that it’s not even remotely considered within Apple’s strategic horizon.

Meanwhile, China is hardly passive in this scenario. Reports indicate that authorities have been actively obstructing shipments of manufacturing equipment from Apple suppliers attempting to move operations out of the country. These measures have reportedly forced companies to devise clever workarounds just to transport their equipment without detection or reprisal.

Ultimately, Apple’s India-made iPhones are less about independence and more about navigating geopolitical tariffs. For now, this shift is primarily a smart legal maneuver to avoid penalties imposed by leaders like Narendra Modi and Donald Trump not a full-fledged exodus from China.