DVD’s have become all too common in our lives. These discs are used to watch movies, install software and transfer data among other everyday tasks. The pictures below provide a glimpse into the process that creates these staples of our daily lives. The images are from a DVD manufacturing plant in Kazakhstan.

The process is mainly automatics and requires only one engineer to keep an eye on it

The main raw material is polycarbonate which comes in large bags shown below

The discs start out as grains of polycarbonate

The grains are first sent to the drying machine

The crystals are melted together into a liquid mass

The liquid mass is crammed into press-form using a stamper inside

Stamper is a metal plate with precise information. The one shown below is a movie which will be on the DVD

The liquid polycarbonate is turned into a disc at 250 degrees and the info is stamped on to it

The workpieces are then cooled

The discs are then covered with a reflective surface so that lasers can read the info

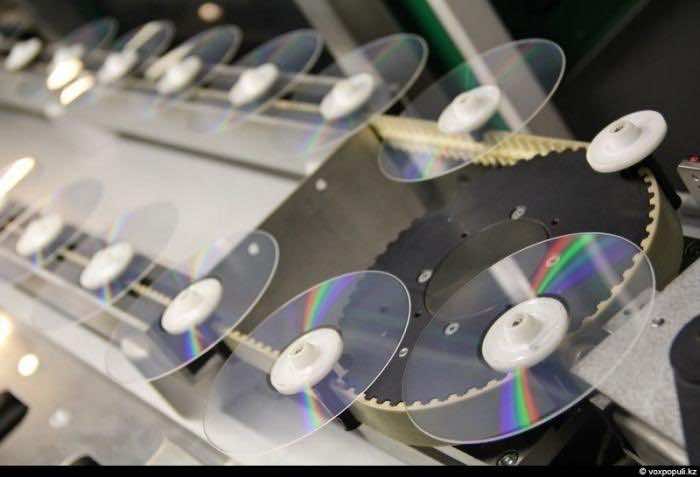

Half-finished DVD’s

Laser inspection is performed to remove bad discs

The discs are then painted

Temporary storage room

Preparing covers for the discs

Hologram to certify the DVD

Workers prepare DVD boxes

The boxes are then wrapped in cellophane film

The distribution center from where DVD’s are sent to different stores

The workers are checked for illegal possession of intellectual property

The DVD arrives at the store