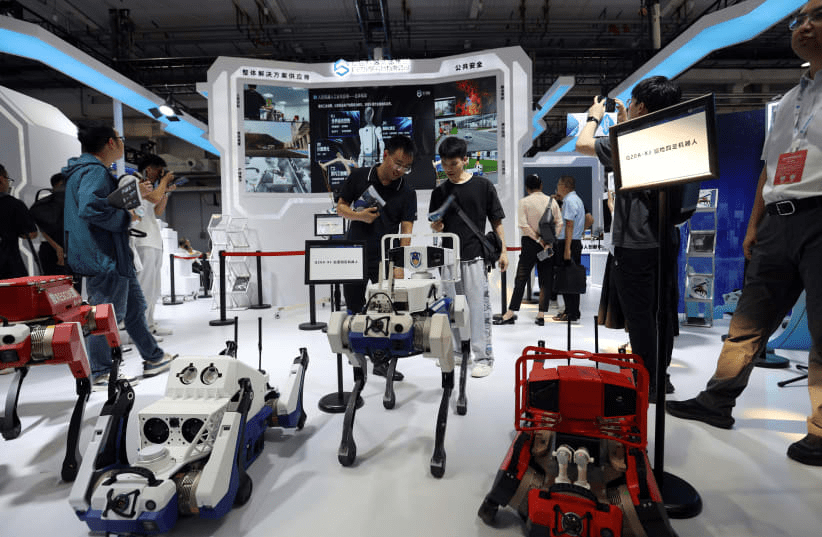

China’s endeavors to spearhead the development of humanoid robots were prominently showcased during the World Robot Conference held in Beijing. While the event highlighted creative and economical supply networks, industry insiders emphasized the need for increased product dependability.

Wisson Technology, a Shenzhen-based firm, is making waves with its flexible robotic manipulators. Unlike traditional robotics that rely on motors and reducers, Wisson uses 3D-printed plastics and pneumatic artificial muscles to power its robots. This low-cost production method allows Wisson to price its robotic arms at about one-tenth the cost of conventional ones, according to Cao Wei, an investor in the company through Lanchi Ventures. Wisson’s pliable arms, priced at around 10,000 yuan ($1,404), could play a pivotal role in the development of humanoid robots, with samples already sent to overseas manufacturers.

However, challenges remain. Yi Gang, founder of Shanghai-based Ti5 Robot, which specializes in integrated joints, highlighted supply chain reliability as a key issue. Due to defect rates, Yi’s company can only produce up to 1,000 units at a time. He identified harmonic gear, crucial for motion control, as a significant bottleneck.

China’s push for robotics innovation aligns with President Xi Jinping’s policies to develop “new productive forces” in technology. The nation’s advanced robotics technology is transforming industries such as manufacturing, autos, agriculture, education, and healthcare. Gao Jiyang, a former executive at autonomous driving start-up Momenta, noted that advancements in smart driving were also accelerating robotics progress, viewing AI-powered cars as a form of robot.

As the conference concluded, Premier Li Qiang emphasized the importance of adhering to Xi’s directives, underscoring the vast potential of the robot industry. He called for increased robot adoption across various sectors, highlighting the industry as a key measure of China’s technological and manufacturing prowess.