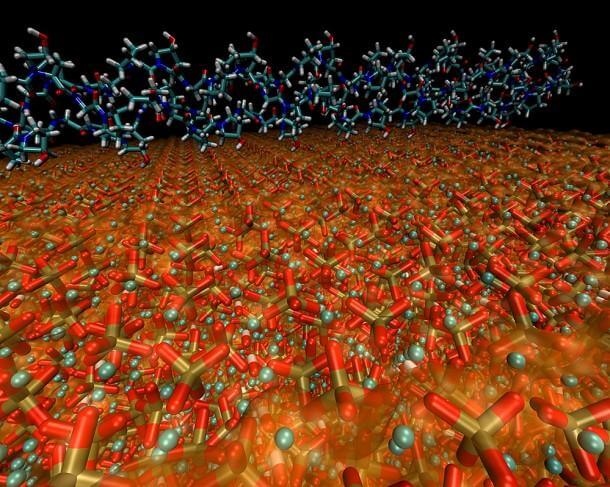

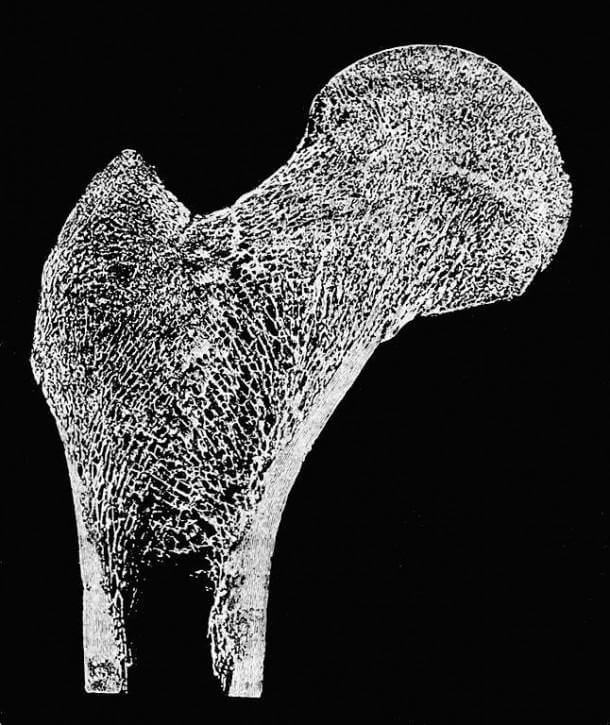

Artificial bone printing has also been made possible by experts at MIT. It is made of collagen protein, elastic in nature and hydroxyapatite minerals that give it the strength thus is making it flexible for movement, yet 22 times as strong as its constituent materials. The components are so well blended that they are perfect to support heavy loads.

Artificial bone printing has also been made possible by experts at MIT. It is made of collagen protein, elastic in nature and hydroxyapatite minerals that give it the strength thus is making it flexible for movement, yet 22 times as strong as its constituent materials. The components are so well blended that they are perfect to support heavy loads.

This research has been carried out by Markus Buehler MIT civil engineering professor and his team. He has been working on 3D printing techniques for quite some time and has worked with various polymers, synthetic materials, etc., and the geometric patterns are also inspired from the naturally occurring materials like real bones or nacre with some additions to the design. His work has been published in Advance Functional Materials.

What came out from the research, were three materials; first simulated mineral calcite, second replicated nacre and third a composite design that was assembled to enhance the human bone structure.

What came out from the research, were three materials; first simulated mineral calcite, second replicated nacre and third a composite design that was assembled to enhance the human bone structure.

After the new bone was created out of the new materials, multiple trials and tests were carried out on it to check its strength. The result showed that the new invention was highly resistant to fractures and thus could withhold great amount of stress.

As one of the team member said, “As engineers, we are no longer limited to the natural patterns. We can design our own, which may perform even better than the ones that already exist.” It is still unlikely that the 3D printed bone will be out in the market anytime soon, but we cannot ignore or underscore the significance it has brought to the field of 3D printing. Let’s hope such development keeps moving forward and we are able to find even better and efficient alternates to the already existing materials.

As one of the team member said, “As engineers, we are no longer limited to the natural patterns. We can design our own, which may perform even better than the ones that already exist.” It is still unlikely that the 3D printed bone will be out in the market anytime soon, but we cannot ignore or underscore the significance it has brought to the field of 3D printing. Let’s hope such development keeps moving forward and we are able to find even better and efficient alternates to the already existing materials.

If some one needs to be updated with most up-to-date technologies after that he must be visit this website

and be up to date all the time.