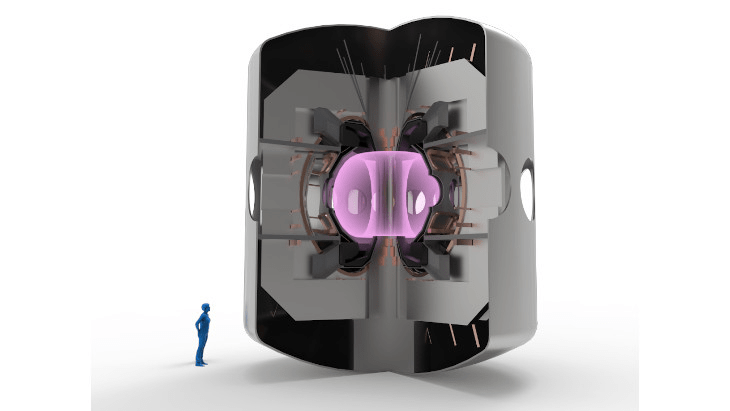

Tokamak Energy, a private fusion energy company, has revealed the initial design of its pilot plant, which promises to deliver 800 megawatts (MW) of fusion power and 85MW of net electricity. The plant, when operational, is projected to power and heat over 70,000 American homes.

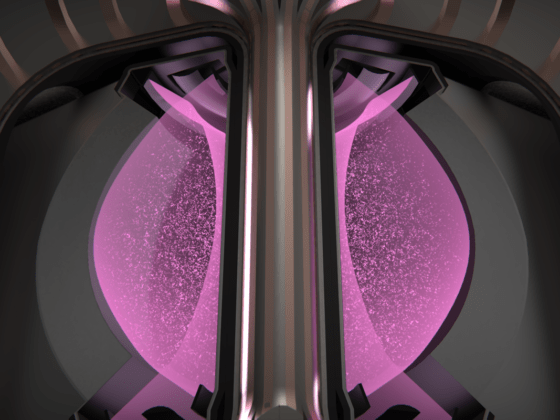

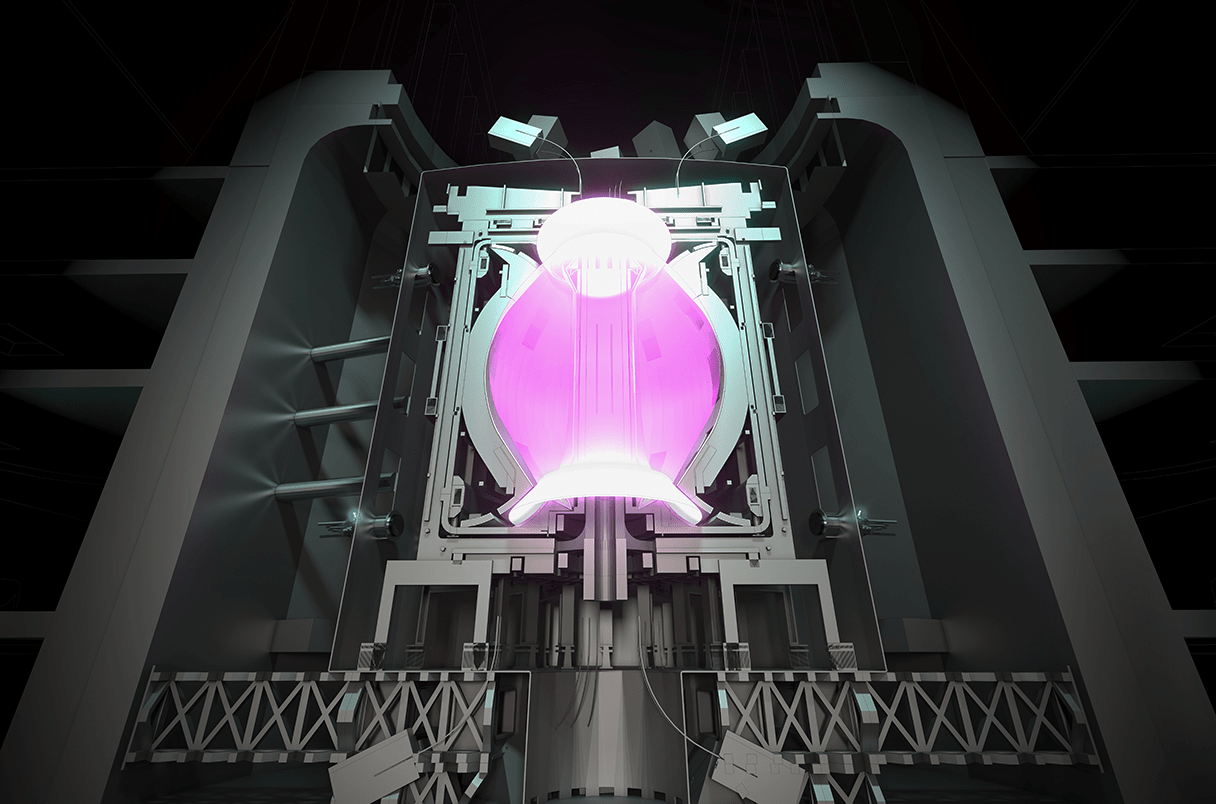

The new design specifies an aspect ratio of 2.0, a plasma major radius of 4.25 meters, and a magnetic field strength of 4.25 Tesla. It also features a liquid lithium tritium breeding blanket—a crucial component for sustained fusion reactions. According to Michael Ginsberg, president of Tokamak Energy, this high-field spherical tokamak has generated “great excitement” within the scientific community, particularly at the prestigious 66th Annual Meeting of the American Physical Society’s Division of Plasma Physics.

Ginsberg emphasized the company’s mission to demonstrate net power generation from the pilot plant by the mid-2030s, to produce globally deployable, carbon-free fusion energy.

Fusion energy is widely regarded as a potential solution to the world’s growing energy needs, offering a clean, safe, and nearly limitless power source. The energy produced by fusion is astonishingly efficient—one kilogram of fusion fuel can release the same amount of energy as burning 10 million kilograms of coal, without harmful emissions.

Tokamak Energy claims a unique position in the private sector, boasting over a decade of experience in designing, building, and operating tokamaks. It is also the first private company to achieve plasma temperatures of 100 million degrees Celsius in a spherical tokamak which is a critical milestone for fusion energy. The company’s design for the fusion pilot plant incorporates high-temperature superconducting (HTS) magnets, which are essential for confining and controlling the hydrogen fuel, in the form of deuterium and tritium, within a plasma that reaches temperatures hotter than the sun’s core.

The development of the fusion pilot plant has been informed by an innovative, iterative workflow. Tokamak Energy utilizes its proprietary PyTOK whole plant systems code to find optimal design points across a range of parameters. This system ensures engineering consistency throughout the process. The designs are then subjected to rapid engineering and physics workflows, allowing for more detailed assessments over two weeks. These evaluations include analyses of neutronics for nuclear heating, tritium breeding ratios, magnet optimization, and plasma exhaust scenarios.

Involving the full team from the early design stage has been essential, according to the company. “By involving the entire team at this early stage, and not fully relying on an integrated code to analyze the design points, we ensure that an integrated and coherent device is carried forward to the next level of fidelity,” a statement from Tokamak Energy reads.

This collaborative approach has positioned the firm as a key player in the U.S. Milestone-Based Fusion Development Program.