Researchers found that 40% of routes today could be electrified in an economically viable manner, before considering environmental costs. They were able to come to this result after modeling 5 to 10 GWh electrified containerships.

This was found in research conducted by teams from the University of California, Berkeley, and Lawrence Berkeley National Laboratory. They have released a study that examines “the technical outlook, economic feasibility, and environmental impact of battery-electric containerships.”

The research shows that electrified containerships have an economic advantage over the internal combustion engine (ICE), even when the costs of environmental and health damages are excluded.

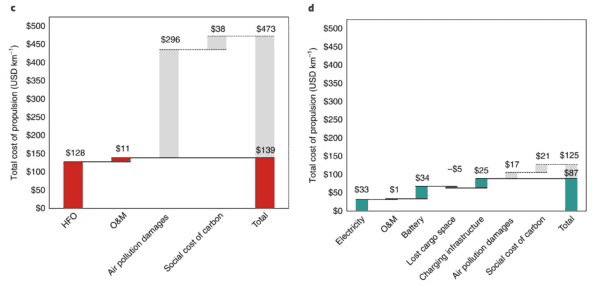

They discovered that ICE containerships cause damages equal to or greater than three times the ship’s costs.

An electrified containership will also cause some environmental damage, however, the estimates of an electrified ship’s air pollution, and the social cost of carbon, are only 1/12th that of an ICE ship.

It is expected that the costs of large ICE containerships will keep on increasing, as electrified containerships become increasingly cost-effective. Conventional ships will cost more than electrified ones.

The authors show that at current battery prices, the electrification of trade routes less than 1,500?km is economical and has minimal impact to ship carrying capacity. And when the authors include environmental costs, the economic range skyrockets to 5,000?km.

A 5,000 km containership would require around 6.5 GWh of LFP batteries.

The choice of batteries for multiple kinds of ships and journeys will also be a point of decision.

The Yara Birkeland is an 80m long, 7MWh electrified autonomous containership that can hold 120 twenty-foot equivalent units (TEU) and makes 12 nautical mile trips.

For ‘Neo-Panamax’ containerships, (sized to fit through the Panama Canal), routes less than 3,000km require less space for batteries and motors than the volume currently occupied by combustion engines and fuel tanks.

If this class of ship travels 20,000km on a single charge, the batteries and motor would require 32% of the ship’s carrying capacity or 2,500 TEU.

The charging infrastructure for a containership traveling less than 10,000km can be accomplished using less than 300 MW.

The infrastructure required to support such massive charging capacities is quite affordable, mainly because of the efficient logistics of ports, since berths are usually occupied more than 50% of the time. At 50% utilization, the researchers modeled that the cost of a 300MW charging station comes to just $0.03 per kWh.

The study has been published here.