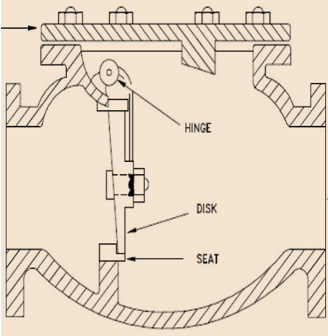

Check Valves or Non-Return Valves are automatic valves that are used mostly in pipelines where the medium flows only in one direction. These valves have a very simple construction and consist of a valve body, bonnet or cover, and a disc. The disc is attached to a hinge and swings away from the valve seat to allow fluid to flow in the forward direction and returns to the valve seat when the upstream flow is stopped. This prevents the reverse flow of fluid.

Depending upon the construction of the valve, check valves can be classified as

1. Swing Check Valve:

This type of valve should generally be installed horizontally in the pipeline, but it can also be installed vertically by keeping in mind that the disc cannot reach the stalling position where the disc stuck in an open position.

The primary advantage of these valves is their ability to allow a complete, unblocked flow – which is especially valuable in piping systems that may require line clean-up. These valves are also suitable for use with manual valves in low-cost systems, such as common-use gate valves.

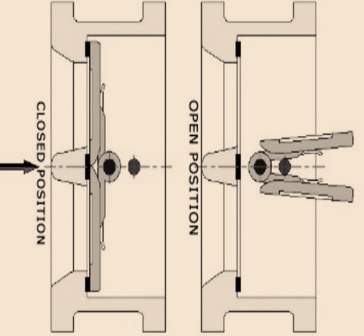

2. Dual Plate Check Valve:

They are also called butterfly check, folding disc check, double disk check, or split check type valve. As the name suggests, two halves of the disk fly towards the centreline with the forward flow and two halves open with the reverse flow and rest on the seat to avoid the flow (Flapping action).

Its lightweight and compact nature make it a preferred option when space and comfort are essential. Installation & maintenance costs are very low as compared to other forms. They are most prominently found in liquid and gaseous low-pressure services.

It is aspecifically designed valve that closes without slamming. The disk of this valve has an internal spring countering the flow pressure of the opening fluid. When a media flow is high enough, the spring compresses and the valve opens; the spring gently forces the disk back to the seating surface in the valve as the flow reduces and slows but reverses the direction of flow before flow.

One of the primary benefits of these valves is their ability to effectively prevent water hammer, thereby eliminating resulting pressure swings, vibrations, and damage.

4. Spring Loaded Check Valve:

These valves can be nozzle check type or silent check type. The quick reaction time of these valves is the most important advantage of this valve. The valve design prevents pressure surges in the line and prevents water hammer.

Some of the other commonly known check valves are

- Ball Check Valve

- Diaphragm Check Valve

- Lift Check Valve

- Stop Check Valve

- Wafer Check Valve

- Duckbill Valve

Check valves can be commonly found in the following applications:

- Gas and liquid pipelines

- Water and steam systems

- Cooling towers

- Water treatment

- Cryogenic applications

- Gas export facilities

- Product tank farms

- Gas storage caverns

- Mine dewatering

Check valves are mechanical devices with simple construction and automatic operation that permit liquids and gases to flow in only one direction, preventing fluid from flowing in the wrong direction.