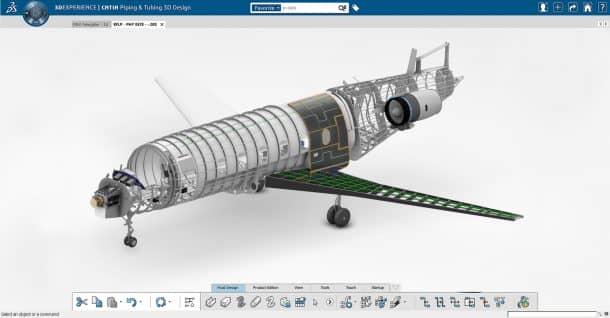

Boeing, the aerospace giant and Swiss technology group Oerlikon have come together in a partnership aimed at advancing 3D printing. The partnership will continue for 5 years and will focus on powder bed additive manufacturing of structural titanium components for the aerospace industry with the goal of standardizing everything from initial powder management to finished product.

There have been many advancements in the recent years in the field of metal-based additive printing. The technology is now moving out of the initial phases and into the mainstream as signified by the Boeing and Oerkilon partnership. Industrial talks about standardization mean that the technology is moving away from exotica and towards routine manufacturing.

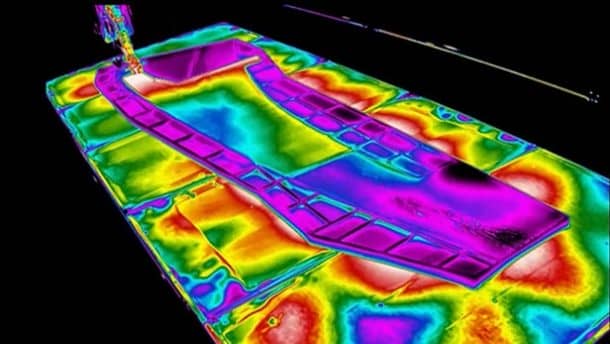

3D printing with metal requires a machine that lays down a layer of metallic powder. A design file is guided by a laser and it moves across the cross-section of the desired product in the bed of powder before another layer is added and the process goes on until the time of completion. The excess powder and any temporary support structures are removed before the final finishing of the component.

Aluminium is relatively easy to work with, but titanium is very difficult to work with no matter what process is used. 3D printing is not any different. The density of titanium is hard to control during the printing process and so is the temperature at which it melts. And, altering the design of the prototype during development becomes a really arduous job.

The agreement currently in place will initially be focused on standardizing titanium-based 3D printing and making sure that the printed components meet US Federal Aviation Administration (FAA) and Department of Defense (DoD) flight requirements as well as quality and cost targets.

“This program will drive the faster adoption of additive manufacturing in the rapidly growing aerospace, space and defence markets,” says Dr Roland Fischer, CEO Oerlikon Group. “Working together with Boeing will define the path in producing airworthy additive manufacturing components for serial manufacturing. We see collaboration as a key enabler to unlocking the value that additive manufacturing can bring to aircraft platforms and look forward to partnering with Boeing.”

This partnership marks a new age of development in 3D technology and we can expect it to bear fruit in the near future.