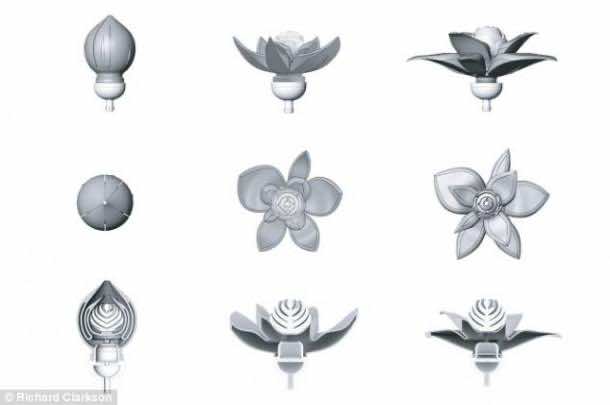

So far, 3D printing has been used to print solid single-shape objects that don’t change in any way. However, Richard Clarkson from the Victoria University of Wellington has become one of the first people to use multi-material 3D printing and create inflatable rubbery flowers.

Unlike previous structures which were rigid, these new models are made from next-generation materials which allow designers, such as Clarkson, to create morphing objects. Created as part of the “Seamless Blossom Project”, the flowers bloom when air is pumped into the inner chambers and reveal a colorful core. According to Clarkson, these flowers are the first ever inflatable objects to be created using 3D printing. He describes the working of the blooming flowers as, “Basically, it’s a curved hollow chamber with flexible rubber. As you inflate it, it creates a gap of air that pushes against the inner layer, forcing the outer layers open. It almost blooms, like a flower.”

The printer used for making the flowers was Objet’s multi-material printer which prints both flexible and rigid materials simultaneously at the point of print. Clarkson designed his project to operate using only air pressure, without the use of any electronics, sensors or computer control. This could be the first in a wave of 3D printed objects which have the capability to morph.

For example, last year an American architect, Skylar Tibbits, announced a project in collaboration with Stratasys, a Minneapolis based group, to create morphing materials. Tibbits has setup a laboratory at MIT to develop self-assembling materials. The concept behind the idea is that the materials will have varying water-absorbing properties that will activate a change in shape once the materials come into contact with moisture. This technology could lead to self-assembling furniture or water pipes that know when to expand to prevent themselves from bursting.