The advent of technology, no doubt, has brought a lot of improvement and development to our world today.

As a result, it has led to the release of more inventions and discoveries that make our lives easy as humans.

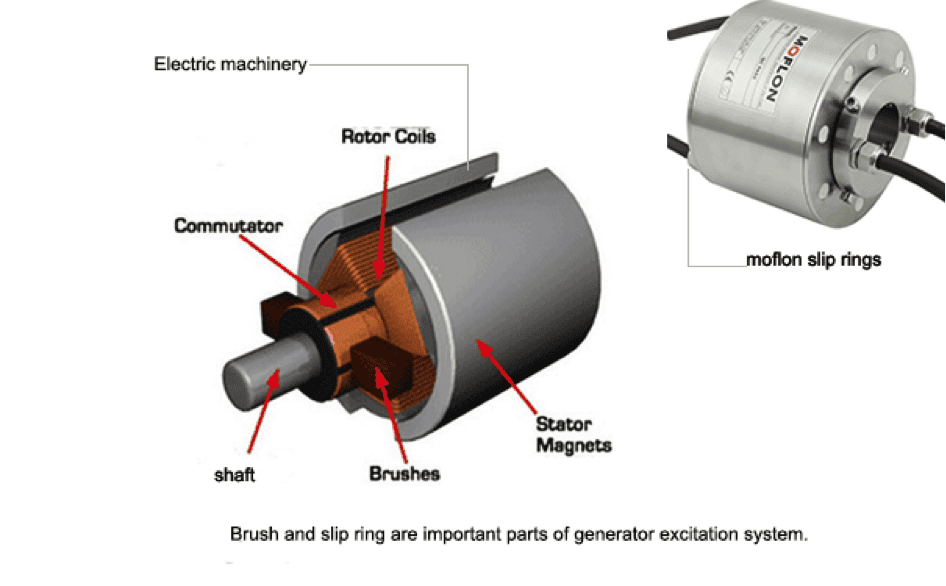

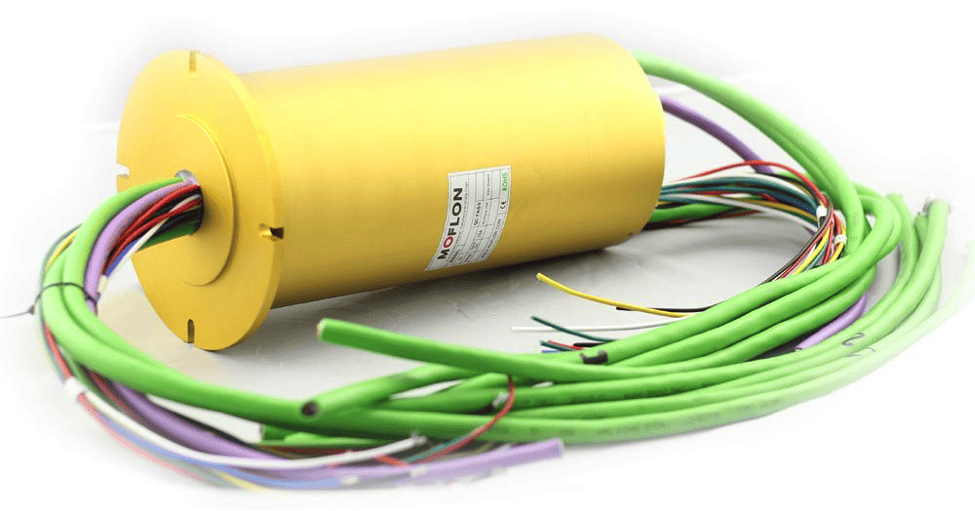

One of such is the slip ring found in AC motors. They enable the electric current to contact the brushes in the AC generator—which eventually supplies current to the coil.

Usually, these brushes maintain close contact with the slip rings to ensure that they work effectively without wearing out quickly.

In many cases, the brushes in the AC motor starts losing contact after working for some time—especially in a high-traffic environment. Unfortunately, this cuts the life span of the slip rings and the brushes in the long run.

But, what if we told you—there are guaranteed ways to extend the life span of the slip rings 10x more.

That’s what this article is all about. Hang in there, and you’ll find out how.

Inspect the Brush Regularly

It’s imperative for you to know the running condition of the slip ring and carbon brushes in the AC motors.

This practice is even more necessary if you’re running a 24/7 system. Thus, in such a scenario, it’s best you do a routine check at night—switch off all lights and carry out an inspection on the brushes and slip rings.

During your routine check, you can confirm if there are any sparks in the slip rings.

Also, it’s essential that you only employ the service of a skilled technician to do the inspection. For instance, it’s the responsibility of a qualified and experienced technician to ensure that the slip ring closes properly after assessment.

If an average company technician, who forgets to close the slip ring handles it, a significant issue may arise.

Thus, it’s essential for you to get a dedicated and skilled technician that will be responsible for inspecting the brushes.

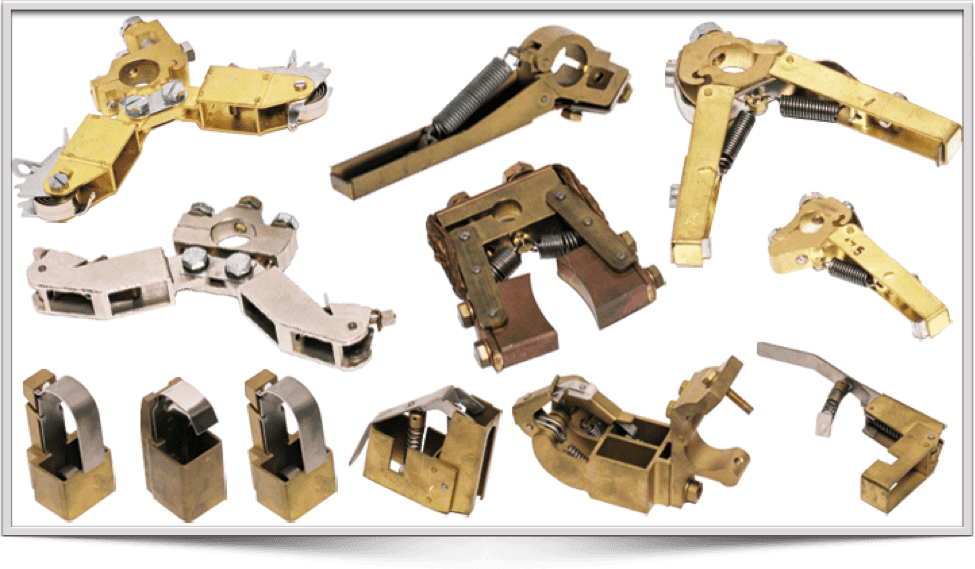

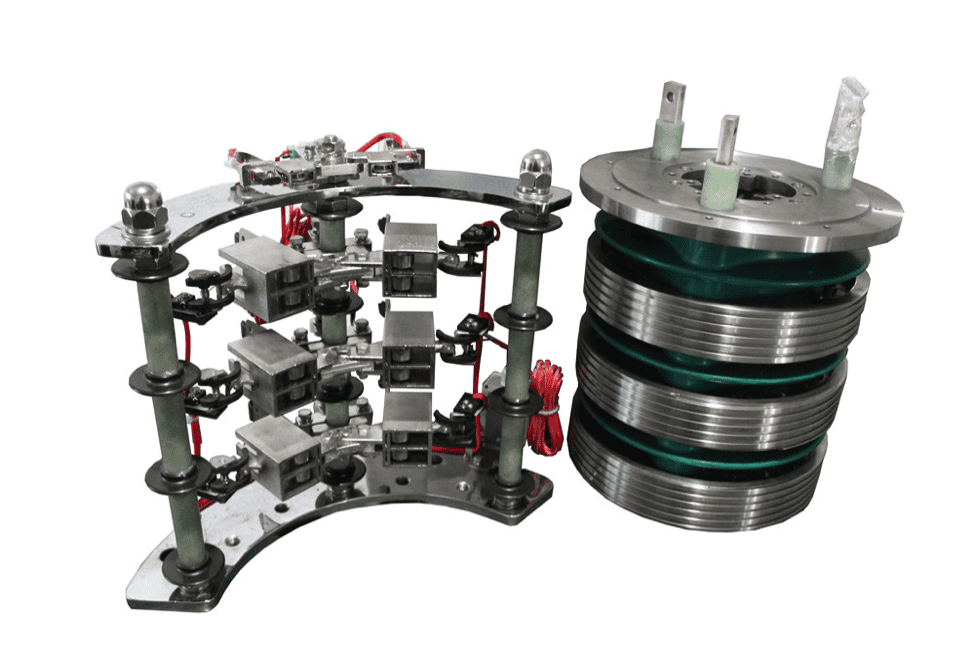

Be Mindful of the Kind of Brush Holder You Get

It’s critical for you to put a close eye on the brush holders. There is always more tension on the brush holder when it works 24/7.

Thus, you must always check for the tension. Less spring tension automatically means that the brush holder won’t press the brush on the slip ring properly.

While the seating of the brush on the slip ring is loose, a chattering occurs in the slip rings. It causes a certain spark and heating of the slip ring. Also, when there is a high brush pressure, it leads to wear and tear of the brush.

When checking the brush holder, ensure that it isn’t sticking anywhere within its movement path.

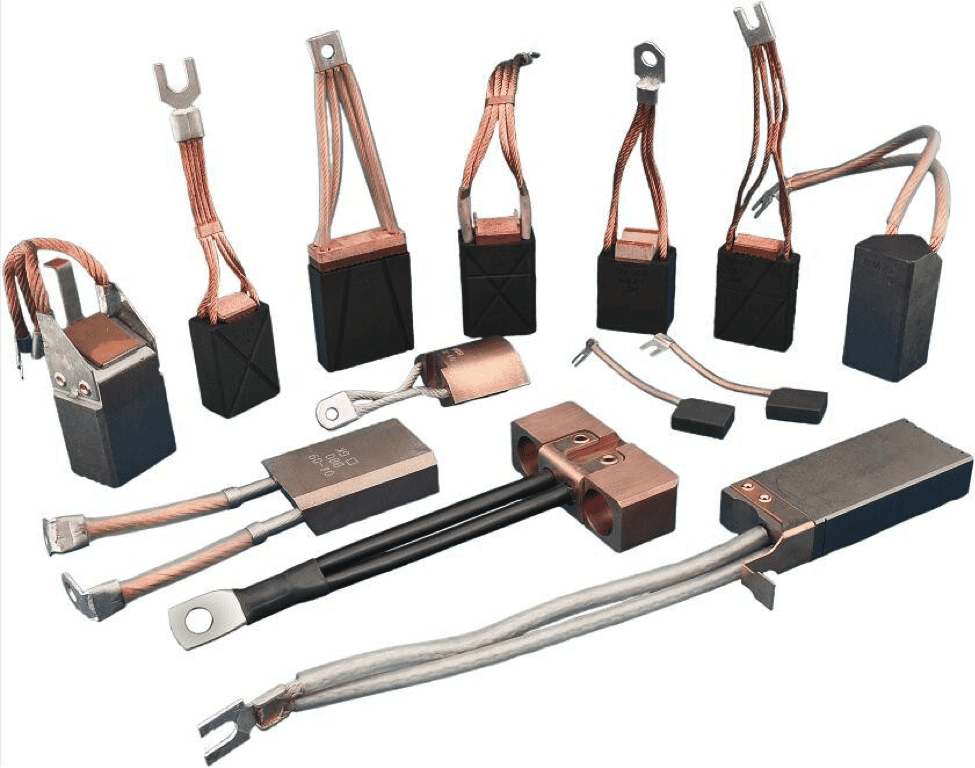

Do a Proper Check to Avoid Fake Carbon Brushes

These days, it’s almost difficult to detect the fakes from the originals in the market, since all the manufacturers are talking high of their products. To avoid such occurrences, go for OEM (Original Equipment Manufacturer) and ditch the cost.

Even if it’s a little bit above your budget, it’s worth every penny, because, in the long run, it will save you more money.

How? When you buy the right one, you save your company the stress and funds of repairs and maintenance over time, especially if your company run a 24/7 service.

That way, you’d have reduced your plant downtime and keep your equipment safe.

Another vital thing to put mind is that you must never use brushes from two different manufacturers in one machine. Such an act can cause an imbalanced share of current between the brushes and eventually lead to overheating.

But, you may ask, “what if the brushes are of the same grade?”

True, they may be of the same grade, but they can never have the same current, temperature handling capacity, and resistance.

The Surface of the Slip Ring

When you newly buy an authentic carbon brush, you’d notice that the slip ring’s seating will have a shiny surface.

During operation, the carbon brush releases the patina to smoothen the slip ring’s surface. Nonetheless, the same patina can leave marks on the surface of the slip ring if the carbon brush faces friction.

Another critical thing to put in mind; the slip ring and brush holder must have the same distance for all holders. Of course, over time, the slip ring will wear a bit because of the brush movements—but it shouldn’t be less than the manufacturer’s warranty period.

With a roughness meter, you can measure the roughness of the slip ring’s surface. Thus, it’s essential to purchase one of these intelligent tools. You can also size the diameter of the slip ring if it’s still round and confirm if the surface already has a runout.

Always Check and Carbon Dust filters

The carbon dust filter is responsible for keeping your slip ring chamber tidy. Carbon dust accumulates in the chamber when the filters are bad.

This carbon dust can stick to the holder and carbon brushes, which eventually limits the smooth operation of the brushes in the holder. As a result, the carbon brush on the slip ring begins to lose and cause some sparks.

Another thing the dust filters do is to disturb the flow of cooling air to the slip ring.

Hence, it’s essential to buy a dust filter that has the following features;

- Nominal Air Flow,

- Filter Class,

- Maximum allowable Pressure,

- Pressure Drop,

- Dust holding capacity

- Maximum Allowable Temperature.

Monitor the Cooling System of the Slip Rings

The contact between carbon brushes and slip ring during operation causes a relatively high temperature.

The reason is simple:

The friction and electrical connection between the brush and slip ring generates a lot of heat. Thus, it’s crucial to ensure the cooling fans, and air path in the slip ring are functional.

Also, it’s best that the slip ring has nothing to do with atmospheric air because it causes moisture—which could be detrimental in the long run.

There are air-flow monitoring sensors that enable the smooth flow of cooling air in the slip rings. It’s best to monitor these sensors and ensure their working perfectly—so you don’t lose your slip rings to over-heating.

Our Final Word

Your company must be able to cultivate a maintenance culture to be able to sustain and extend the life span of the slip rings in AC motors.

One great way to make that work is by doing the things you read in this article, and you can rest assured that you’ll be saving a ton of repair money for your company.