In the modern industry, any high-tech products are inseparable from precision manufacturing, which is particularly shown in automotive, artificial intelligence, consumer electronics, Internet of things, rockets, missiles and artificial satellites. It can be said that precision manufacturing represents the manufacturing technology level of a country and an enterprise. With successive generations, 5-axis CNC has become the main instrument for precision machining. In this article, we will briefly introduce the characteristics of CNC and 5-axis CNC, and what WayKen has done in precision CNC machining services.

Introduction to Precision Manufacturing

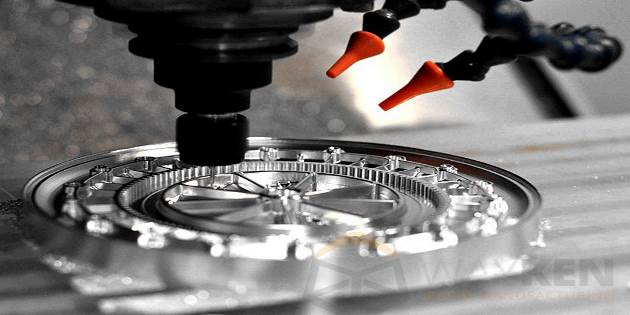

Since the industrial revolution, human beings have been pursuing scientific and technological progress, precision manufacturing main pursuit on the machining precision and surface quality, it is not only a quick response to market demand, improve productivity, and is an effective measure to guarantee the quality of the products. Generally speaking, the processing accuracy of 0.1-10um and the surface roughness Ra value of 0.3-0.8um are precision manufacturing. Precision machining usually includes precision cutting (turning, milling, engraving, etc.), precision grinding and polishing, etc.

As we all know, it’s necessary to have effective tools to do good work, so, many precision machining to rely on automation instrument to achieve expectations. Since the industrial revolution, countless workers in science and technology have been searching for a machine that can be precisely machined. With successive generations, 5-axis CNC has become the main instrument for precision machining.

The application of numerical control technology has not only brought revolutionary changes to the traditional manufacturing industry, making the manufacturing industry a symbol of industrialization, but also with the continuous development of numerical control technology and the expansion of the application field, the development of some important industries such as national defense, automobile, etc. for international people’s livelihood is playing an increasingly important role. More and more CNC is used for precision machining, especial the 5- axis CNC.

The Development and Character of CNC

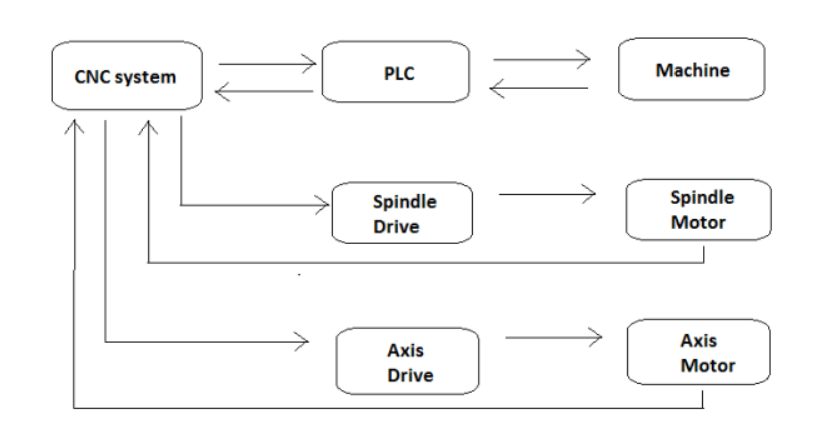

Early numerical control system is composed of hardware circuits called Hard NC, after the 1970s, hardware circuit components gradually replaced by a special computer and called computer numerical control system, generally using a special computer and equipped with interface circuit, can achieve the control of multiple CNC equipment action. So now the numerical control is generally CNC (computer numerical control). It is the technology that uses computer to realize digital program control. This technique USES a computer to perform logic control functions over the movement of a device and its peripherals using a previously stored control program. As the computer replaces the original numerical control device composed of hardware logic circuits, the storage, processing, operation, logic judgment of input operating instructions and other control functions can be realized by computer software. The tool used for CNC milling is called a CNC milling machine or CNC machining center. The lathe that performs CNC turning is called the CNC turning center. CNC machining G code can be programmed manually, but usually machining workshop with CAM (computer-aided manufacturing) software automatically read files and generate G code program, CNC machine control.

CNC play a very important role in precision machining, so it is very important for designer to understand the characteristics of CNC.

(1) Geatly reduce the number of tooling, processing complex shape parts do not need complex tooling. If you want to change the shape and size of the parts, you only need to modify the parts processing procedure, which is suitable for the development and modification of new products.

(2) Stable processing quality, high processing accuracy and repetition accuracy, to meet the requirements of precise instrument processing.

(3) Multiple varieties, small batch production of higher production efficiency, can reduce the production preparation, machine tool adjustment and process inspection time, and because of the use of optimal cutting and cutting time.

(4) Can process conventional methods difficult to process complex surface, even some processing parts can not be observed.

But the disadvantage of CNC machining is the high cost of machine tools, requiring maintenance personnel with a higher level

Development and Characteristics of 5-axis CNC

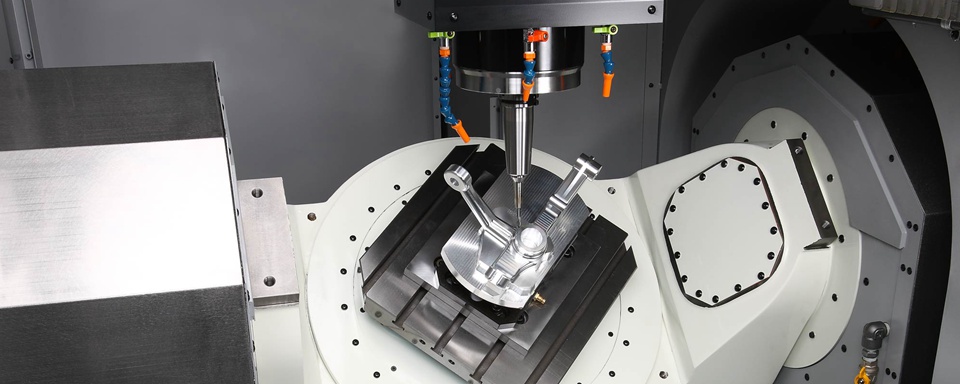

Traditional CNC machining generally uses 3-axis machining center and vertical machining center to complete the workpiece milling. with the development of manufacturing technology, the traditional CNC machining is widely used, but traditional CNC production efficiency is low, become poor precision seiko production precision and the main problems of science and technology innovation, make the weakness of traditional CNC machining is gradually revealed. In order to overcome the problems of traditional CNC machining accuracy, improve the precision machining level and production efficiency, 5-axis CNC overcomes these shortcomings and becomes the main instrument for precision machining.

Compared with traditional 3-axis CNC, 5-axis CNC machining has these advantages

1. Reduce processing time

In five-axis machining, horizontal end milling cutters are used to maintain the vertical state of the machining surface of complex molds, which can greatly reduce the processing time. The principle of five-axis machining center is also applicable to side milling with inclined surface, which can eliminate the ribbed line caused by ball-head milling cutter, making the surface effect of the mold more ideal, but also reduce the cause

Manual work required to clean the mold surface.

2. Improve machining accuracy

Through five-axis machining, the second clamping can be reduced, the possibility of error is greatly reduced, and the machining accuracy is guaranteed

3. High production efficiency

Five axis machining center can effectively reduce the parts processing time and auxiliary time, five axis linkage machining center spindle speed and feed range, allow machine into

Heavy cutting, five axis machining center is now entering the era of high-speed machining, five axis machining center moving parts of the rapid movement and positioning

High speed machining reduces the turnover time of semi-finished products and improves the production efficiency.

WayKen’s Contribution to Precision Manufacturing

5-axis CNC is the main instrument for precision machining. With more than 20 years’ experiences of prototype manufacturing, WayKen have 5-axis CNC for precision machining instrument, which can meet customers’ high precision requirements in production. More than 20 years of experience in precision machining is an important sell-point of WayKen, which have provided 5000+ high-precision products for enterprises that need high-precision prototype services. Not only save the cost of research and development, but also provide customers with precision parts, improve the development of the field of scientific and technological innovation.

WayKen will continue to uphold the trend of made in China 2025 and industry 4.0, and continue to contribute our wisdom and strength in the field of precision manufacturing. Try our best to help domestic and overseas scientific and technological innovation enterprises research and development. WayKen has always been a practitioner, contributor and striver in the field of precision manufacturing.