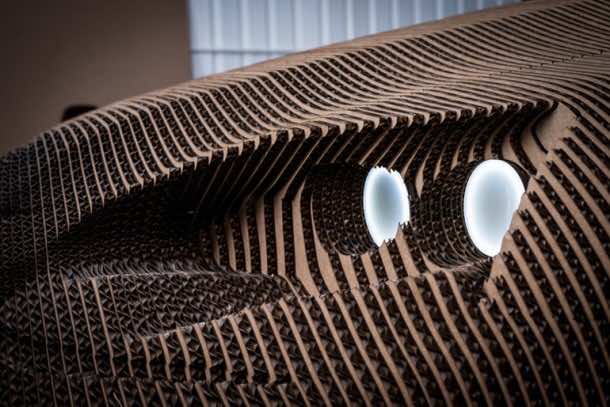

Cardboard and its uses have never failed to surprise us, however, when Lexus creates a cardboard that can be driven; mind = blown! Meet the Origami Car that is a life-size version of the Lexus IS saloon and has been created using cardboard.

The project has been executed as a publicity stunt of course, however, it does celebrate the Lexus’ “takumi craftsmen and women”. The finished model can be driven and that’s what makes it so special. It was created in collaboration with LaserCut Works and Scales and Models with a team comprised of five professional designers and modelers. A total of 1,700 cardboard sheets each measuring in at 10mm thick were employed and were laser cut to the required sizes.

It was built on a steel and aluminum frame and has been powered by an electric motor to make it move forward and backward. Apart from this, it comes with an interior and functional doors, headlights and rolling wheels that have been created using layered sheets of cardboard.

The design was based on a 3D model that was given by Lexus. The team proceeded by dividing the model into a number of sections that included the dashboard, main body, seats and the wheels. The sheets of cardboard were then cut and numbered to facilitate the assembly. These pieces were then layered by hand via water-based glue.

Ruben Marcos, Scales and Models Company founder and director, said, “The seats took a few attempts to get just right and the wheels required a lot of refining. Once we could see the physical pieces taking shape, we could identify where we needed to make improvements – as with anything, there were some elements of trial and error, but as we had all the resources we needed in-house, this made the changes easier to produce.”

It was completed within three months. Check out the video below.